Preparation and application of soluble polymer microneedle for enhancing light transparency of skin

A polymer and soluble technology, applied in the measurement of color/spectral characteristics, fluorescence/phosphorescence, scattering characteristics, etc., can solve the problems of limiting the application range of optical imaging technology, complicated operation of physical methods, and toxic and side effects of human body, etc. Transparency, non-toxic and side effects, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Another embodiment of the present invention provides a method for preparing a soluble polymer microneedle for enhancing skin light transparency, the method comprising: containing one or more of hydroxyl, amido, carboxyl, amino Dissolving the soluble polymer into a solvent to obtain a polymer solution, pouring the polymer solution onto a microneedle mold, removing air bubbles in a vacuum, drying and peeling off, to obtain the soluble polymer microneedle.

[0038] Wherein, the mass fraction of the soluble polymer in the polymer solution is 1%-70%. The solvent is one or more of deionized water, ethanol, ethylene glycol, propanol, acetic acid, acetone, and anhydrous dichloromethane.

[0039] Yet another embodiment of the present invention provides a method for preparing a soluble polymer microneedle for enhancing skin light transparency. The method further includes adding one or more The soluble polymer and optical transparent agent are dissolved in a solvent to obtain a p...

Embodiment 1

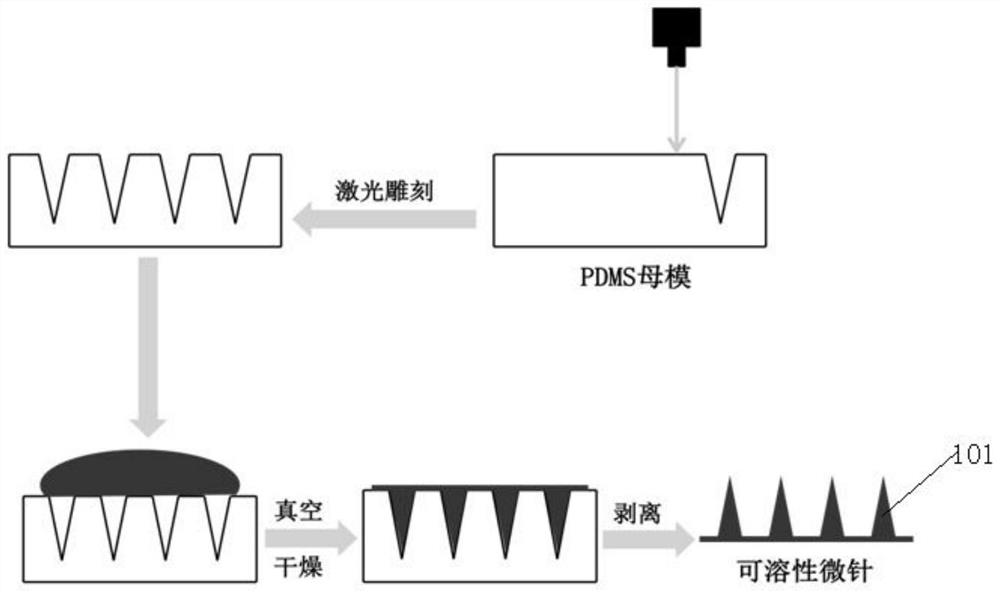

[0044] This example provides a method for preparing a soluble polymer microneedle. see figure 1 , the method includes the following steps:

[0045] (1) Mix the PDMS prepolymer and the curing agent at a ratio of 10:1w / w, stir well, then vacuumize, and put it in a vacuum oven at 80°C for 2 hours to obtain a PDMS die. Then the laser beam is drilled on the flat and hardened 1cm×1cm PDMS module to form a series of neatly arranged tapered holes. The depth of the holes is 300 μm. Thus, four PDMS microneedle molds with different numbers of holes were obtained.

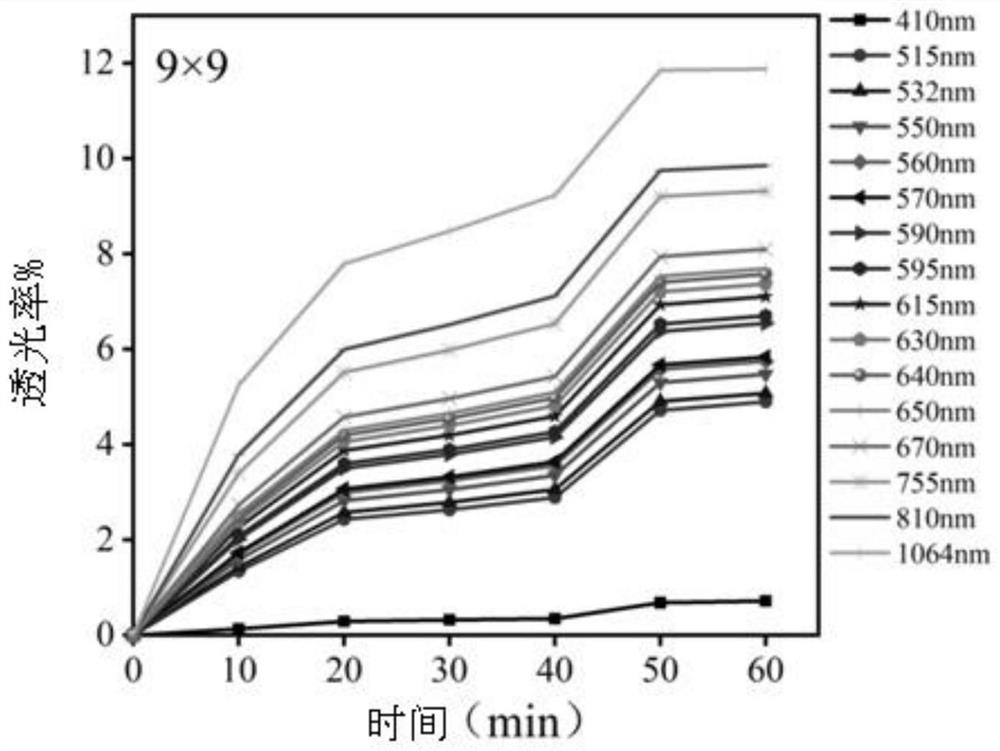

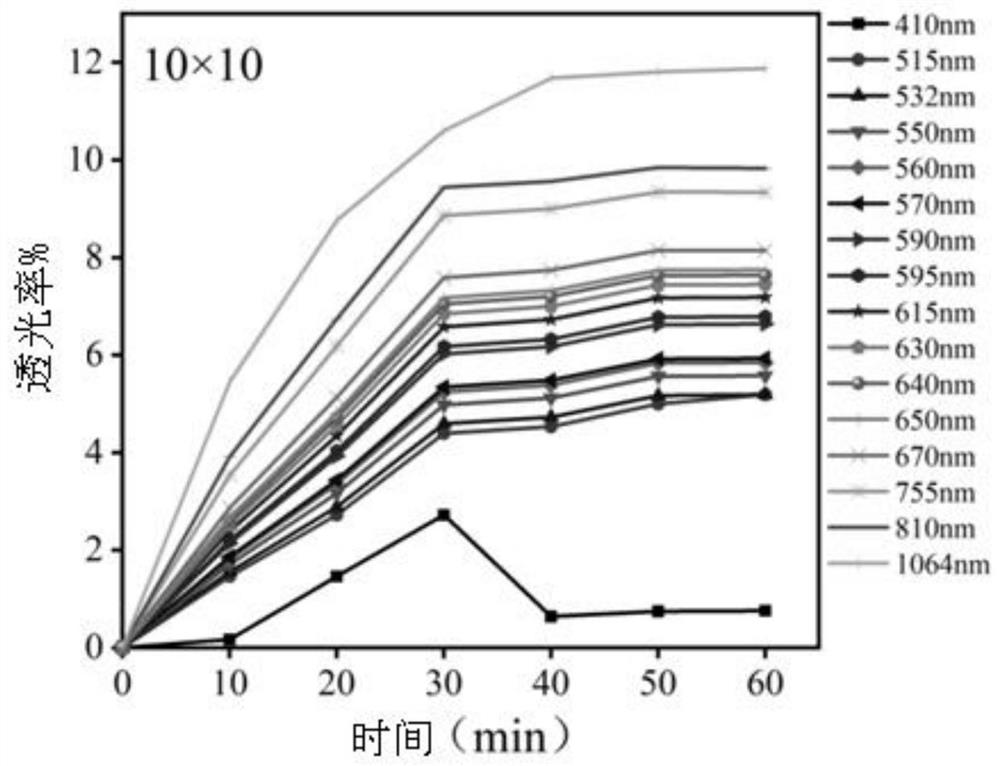

[0046] (2) Add 100 mg of hyaluronic acid (20-40 kDa) powder gradually into 1000 μL of deionized water, stir well, and prepare a uniform polymer solution. Pour the prepared solution into 4 PDMS microneedle molds with different numbers of holes, and then put it into a vacuum drying oven and use 85KPa to evacuate for 10min twice to remove air bubbles and allow the solution to better enter the PDMS mold. in the pores. After ...

Embodiment 2

[0053] This example provides a method for preparing a soluble polymer microneedle. The method includes the following steps:

[0054] (1) Mix the PDMS prepolymer and the curing agent at a ratio of 10:1w / w, stir well, then vacuumize, and put it in a vacuum oven at 80°C for 2 hours to obtain a PDMS die. Then the laser beam is drilled on the flat and hardened 1cm×1cm PDMS module to form a series of neatly arranged tapered holes. The depth of the holes is 300 μm. Thus, four PDMS microneedle molds with different numbers of holes were obtained.

[0055] (2) Add 0.9 mg of dextran (50-70 kDa) and 89.1 mg of polyvinyl alcohol (100-110 kDa) gradually into 210 μL of deionized water, stir on a magnetic stirrer and heat to boiling to obtain a polymer mixed solution. After cooling to room temperature, pour the prepared solution into 4 PDMS microneedle molds with different numbers of holes, and then put it into a vacuum drying oven and use 85KPa to evacuate for 10min twice to remove air bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com