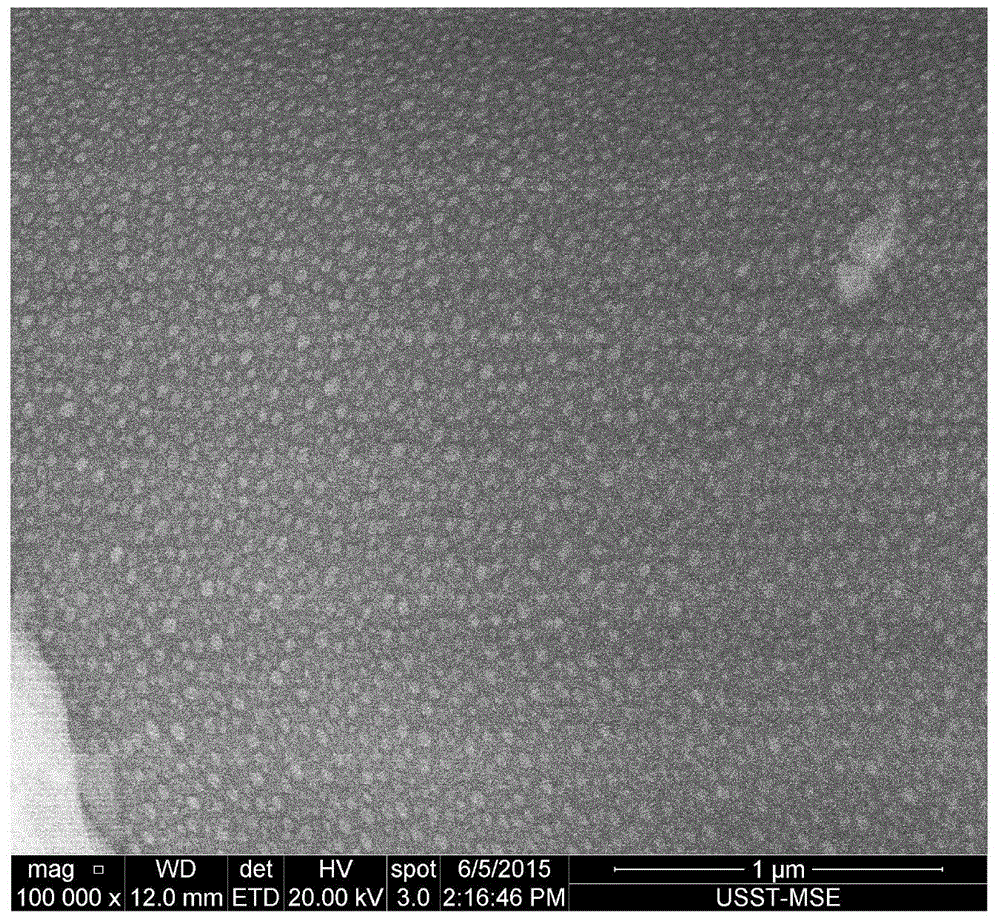

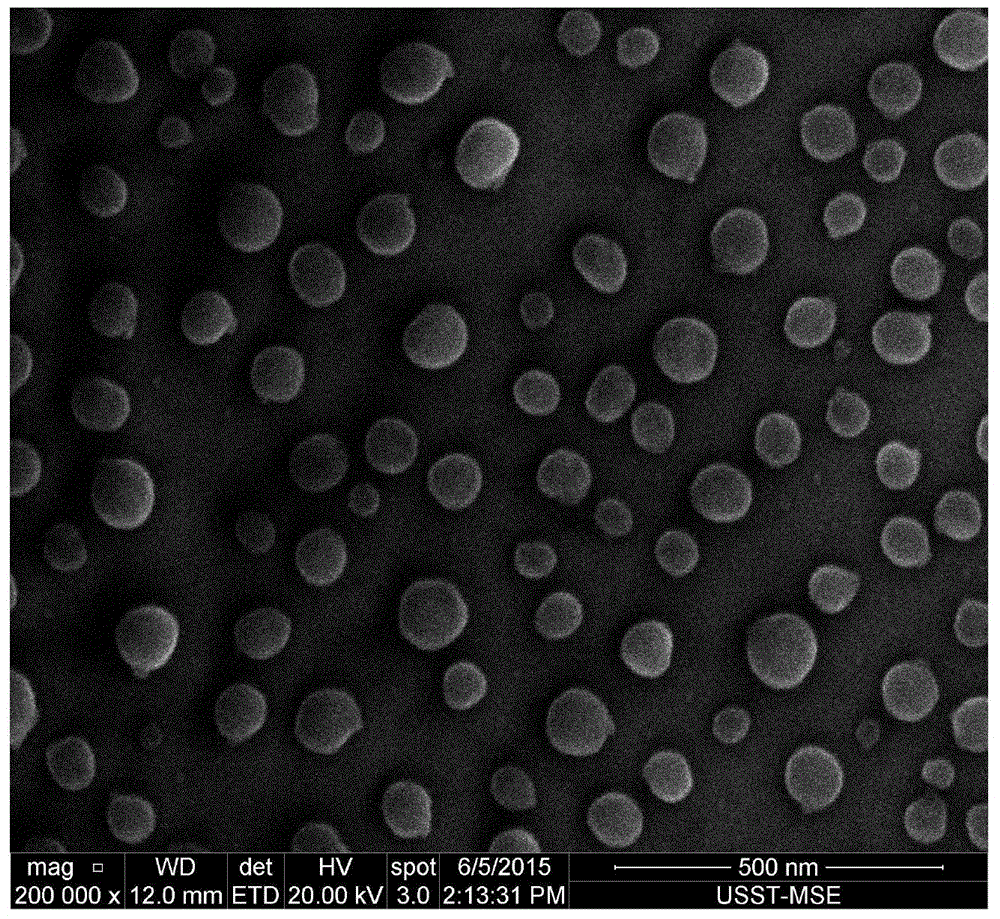

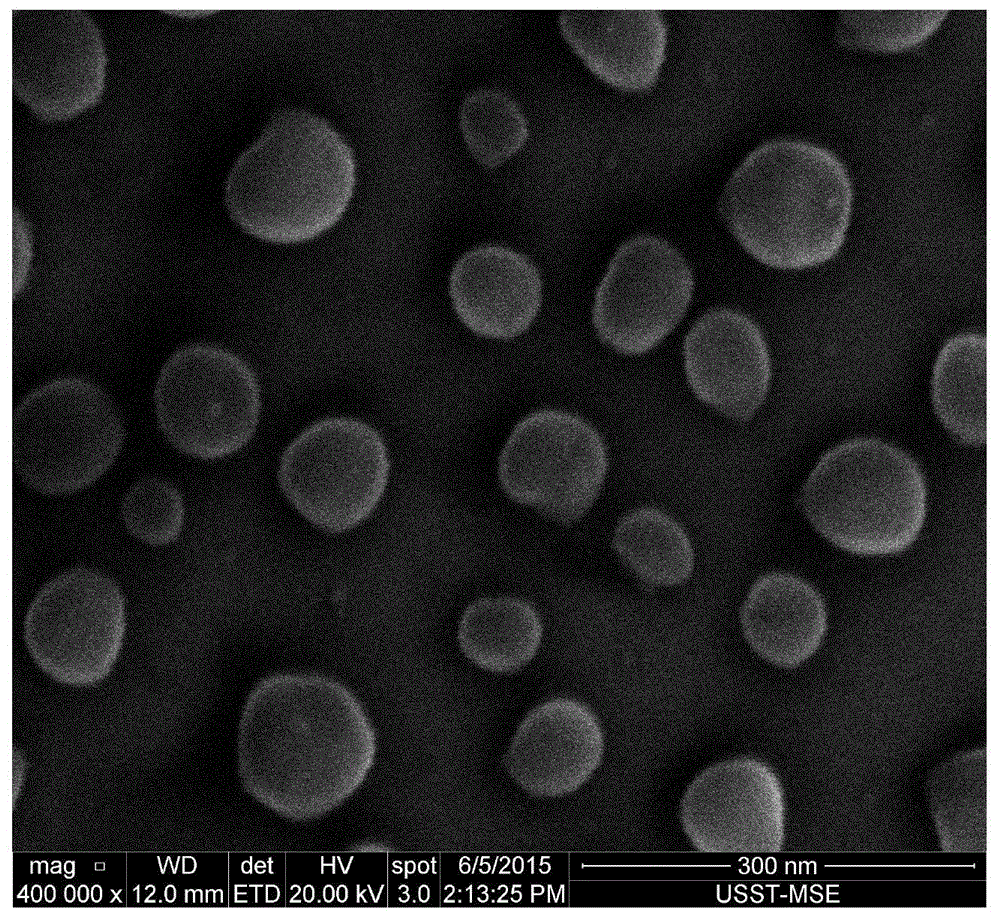

Preparation method capable of continuously adjusting particle size of silver nanospheres

A silver nanometer and pellet technology, applied in nanotechnology and other directions, can solve the problems of inability to large-scale production, complicated procedures, and yield control, and achieve the effects of convenient particle size, stable chemical properties, and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In the first embodiment, the incident method adopts the magnetron sputtering method.

[0029] i) Install the ultrasonically cleaned quartz substrate on the substrate fixture with an inclination of 5°, and place the movable baffle between the substrate fixture and the sputtering target;

[0030] ii) vacuumize the vacuum chamber, the vacuum degree of the vacuum chamber reaches 5×10 -4 Above Pa, then pass argon into the vacuum chamber (you can choose argon, or a mixed gas of argon and oxygen, etc. according to the needs), so that the air pressure in the vacuum chamber reaches the working pressure, and the working pressure is 0.8Pa;

[0031] iii) Heating the quartz substrate, reaching the set temperature of 50° and injecting metallic silver particles;

[0032] iv) After the metal silver particles are evenly incident, rotate the substrate fixture, and then remove the movable baffle, and the metal silver particles (the purity of the metal silver particles is above 99.99%, th...

Embodiment 2

[0037] The incident method in the second embodiment adopts the magnetron sputtering method.

[0038] i) Install the ultrasonically cleaned K9 substrate on the substrate fixture with an inclination of 30°, and place the movable baffle between the substrate fixture and the sputtering target;

[0039] ii) vacuumize the vacuum chamber, the vacuum degree of the vacuum chamber reaches 4.5×10 -4 Above Pa, then pass argon into the vacuum chamber (you can choose argon, or a mixed gas of argon and oxygen, etc. according to the needs), so that the air pressure in the vacuum chamber reaches the working pressure, and the working pressure is 0.8Pa;

[0040] iii) Heating the K9 substrate, reaching the set temperature of 300°, injecting metallic silver particles;

[0041] iv) After the metal silver particles are uniformly incident, the substrate fixture is rotated, and then the movable baffle is removed, and the metal silver particles are deposited on the K9 substrate;

[0042] v) After 20 ...

Embodiment 3

[0046] In this embodiment, the incident mode adopts thermal evaporation mode.

[0047] i) Install the ultrasonically cleaned silicon wafer substrate on the substrate fixture at an angle of 85°, and place the movable baffle between the substrate fixture and the sputtering target;

[0048] ii) vacuumize the vacuum chamber, the vacuum degree of the vacuum chamber reaches 4.5×10 -4 Above Pa, then pass argon into the vacuum chamber (you can choose argon, or a mixed gas of argon and oxygen, etc. according to the needs), so that the air pressure in the vacuum chamber reaches the working pressure, and the working pressure is 0.8Pa;

[0049] iii) Heating the silicon wafer substrate to inject metallic silver particles after reaching the set temperature of 400°;

[0050] iv) After the metal silver particles are uniformly incident, the substrate fixture is rotated, and then the movable baffle is removed, and the metal silver particles are deposited on the silicon wafer substrate;

[0051]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com