Mesoporous iridium pyridine heterogeneous catalyst, its preparation method and application

A heterogeneous catalyst, catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve the problem of low chemical and thermal stability, waste of resources environment , difficult to recycle and other problems, to achieve high chemical and thermal stability, wide application, the effect of eliminating the diffusion of reaction substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Example 1: Preparation of mercapto-functionalized mesoporous silica foam matrix (SH-MCF):

[0060] Mix P123 (4.000g) and hydrochloric acid solution (150mL 1.6mol / L), then stir at 37°C for 2h until the solution becomes clear, then add 1,3,5-trimethylbenzene (4.6 mL), ammonium fluoride (0.0460g), then stirred at a temperature of 37°C for 1h; then added TEOS (7.34mL) dropwise to the solution, and then stirred at a temperature of 40°C for 4h; MPTMS (1.15mL) was added dropwise to the mixture, and aged for 20h under medium-speed stirring; then the mixture was poured into a polytetrafluoroethylene-lined autoclave, and then aged at a temperature of 100°C 24h; then the mixture was separated by filtration, washed with ethanol, and then dried in vacuum at 80°C for 12h to obtain a white powder; finally, the white powder was dispersed in a mixture of hydrochloric acid and ethanol (200mL, volume ratio 2:100) solution, and then refluxed at a temperature of 80° C. for 4 h; centrifuged...

Embodiment 2

[0061] Embodiment 2: the preparation of homogeneous iridium pyridine catalyst (IrL):

[0062] Diisopropylammonia (0.8mL), n-butyllithium n-hexane (3.5mL, 1.6mol / L) and anhydrous tetrahydrofuran (10mL) were mixed, then stirred at -78°C under nitrogen protection for h; Add 4,4'-dimethyl-2,2'-bipyridine (1g) and anhydrous tetrahydrofuran (45mL) to the mixed solution, then stir for 15min at -78°C; then Stir at 0°C for 1h; then add allyl bromide (0.72g) and anhydrous tetrahydrofuran (15mL) to the mixed solution, then stir for 12h at a temperature of 25°C; then add methanol ( 5mL), then vacuum dried to obtain the crude product; then the crude product was dissolved in dichloromethane, and washed with deionized water, brine, MgSO 4 The solid was dried, and finally the oily substance 4-(3-butenyl)-4'-methyl-2,2'-bipyridine was obtained by column chromatography; then 4-(3-butenyl)-4' -Methyl-2,2'-bipyr (0.0986g), chlorotetrakis[2-(2-pyridyl)phenyl]diiridium(III)(0.214g), ethylene glyc...

Embodiment 3

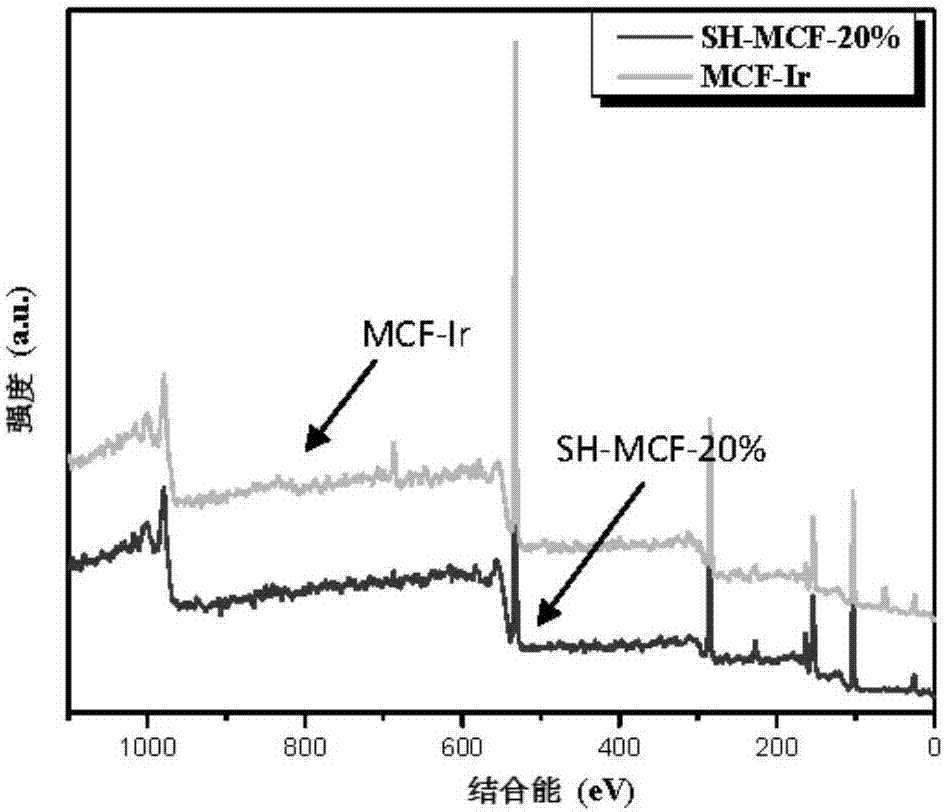

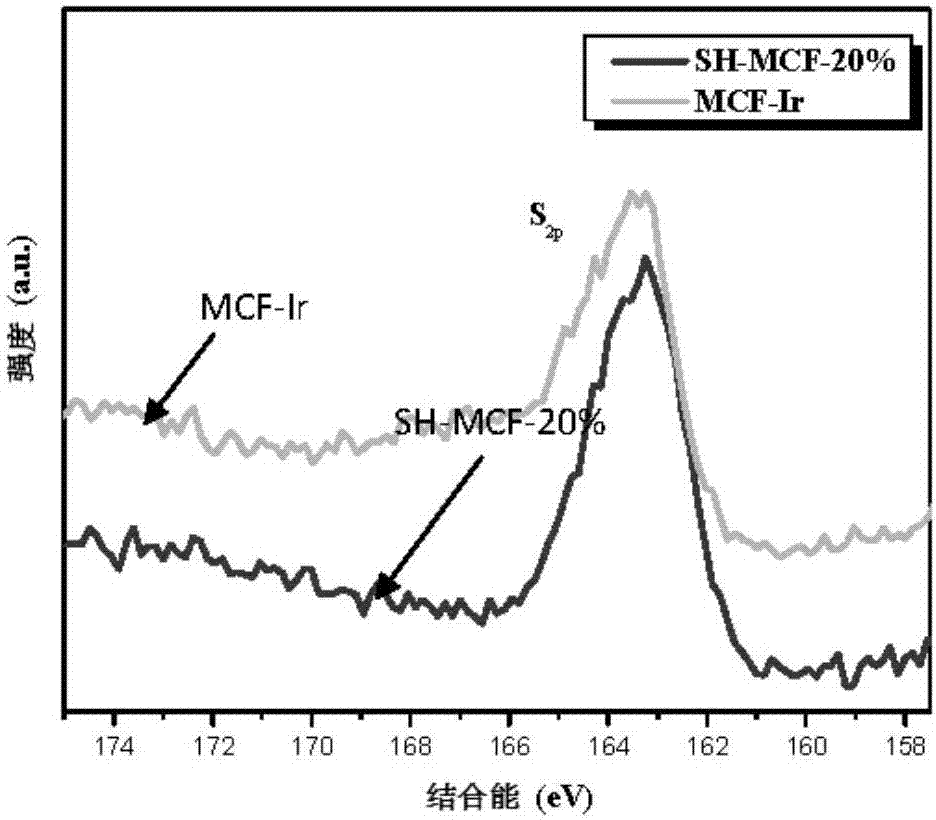

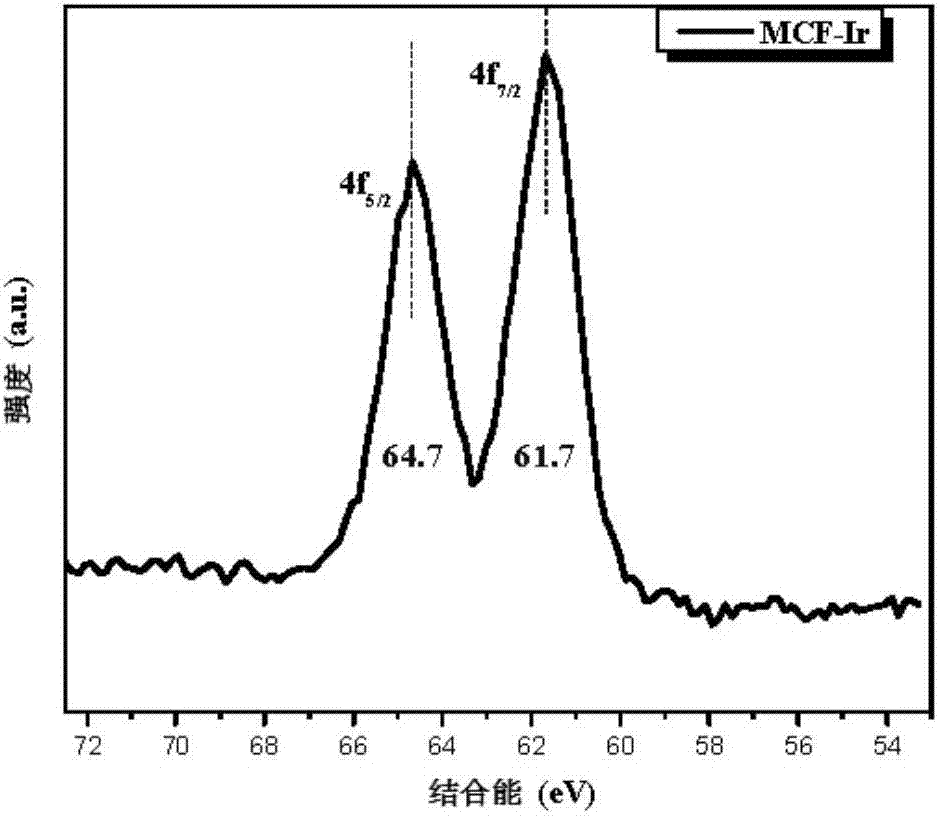

[0063] Embodiment 3: the preparation of mesoporous iridium pyridine catalyst (MCF-Ir):

[0064] First iridium pyridine catalyst (0.0500g), SH-MCF (0.1000g), AIBN (0.0200g) CHCl 3 (10mL) were mixed, and then refluxed in a nitrogen atmosphere for 24h; finally filtered, washed, and dried (80°C) to obtain a mesoporous iridium pyridine heterogeneous catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com