A kind of rare earth nanocomposite catalyst and its preparation method and application

A nanocomposite and catalyst technology, applied in the direction of catalyst activation/preparation, preparation with chloride, chemical instruments and methods, etc., can solve the problems of expensive catalyst preparation, reduced industrial application value, loss of active components, etc., to avoid sintering Effect of inactivation phenomenon, improvement of utilization rate and responsiveness, and increase of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: Preparation and Application of Unloaded Particulate Rare Earth Nanocomposite Catalysts

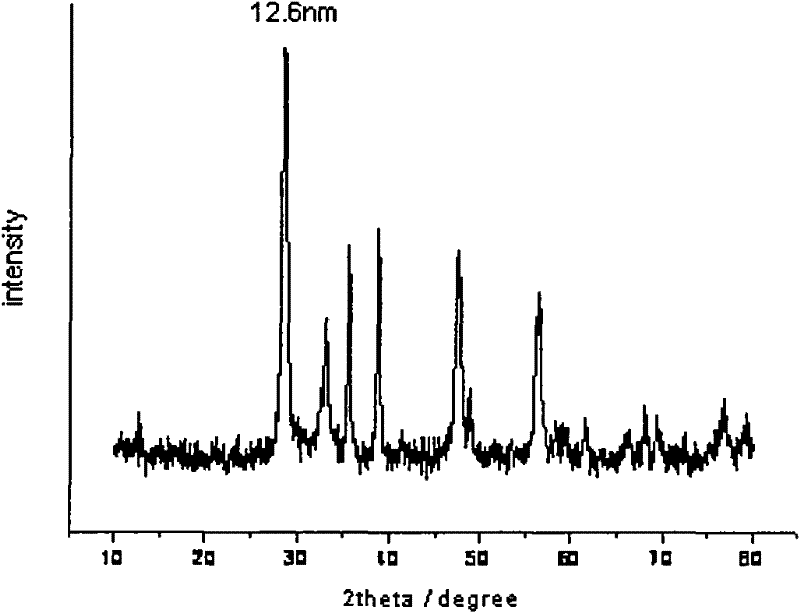

[0038] 17.5g (0.04mol) Ce(NO 3 ) 3 .6H 2 O, 13.5g (0.08mol) CuCl 2 .2H 2 O. 5.5g (0.07mol) of KCl was added to 490g (27mol) of deionized water, fully dissolved, then 61g (0.32mol) of citric acid was added, and vigorously stirred for 12h to obtain solution A. After preparing solution A, stir vigorously in a constant temperature water bath at 60°C until a gel is formed, put the gel into an oven at 120°C to foam for 12 hours, and then bake it at 450°C for 4-6 hours to obtain unsupported particles Type rare earth nanocomposite catalyst powder, that is, hydrogen chloride oxidation catalyst type I. Its XRD spectrum is shown in figure 1 .

[0039] In a 60mL three-phase slurry reactor, 8g of the above-mentioned catalyst type I are loaded, and the reaction medium is composed of 54g of inert molten salt composed of zinc chloride, potassium chloride and sodium chloride, and t...

Embodiment 2

[0040] Example 2: Preparation and Application of Supported Rare Earth Nanocomposite Catalysts

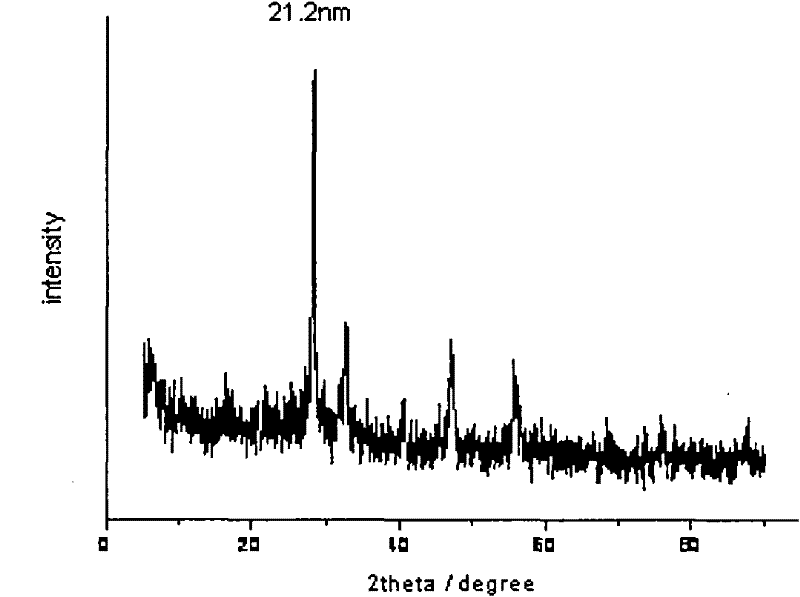

[0041] The catalyst preparation method described in Example 1 was adopted, except that after the solution A was obtained, 50 g of ReY molecular sieve carriers with a particle size of 110 mesh were added, and stirring was continued in a constant temperature water bath at 60° C. until a dense gel was formed. Put the gel in an oven at 120°C for 12 hours, and then bake it at 450°C for 4 hours to obtain a supported rare earth nano-catalyst powder; mix the nano-catalyst powder with 20 g of silica sol; extrude it with an extruder , cut into lengths of 1-3 mm, dried in an oven at 120°C for 12 hours, and then calcined in a muffle furnace at 450°C for 4 hours to obtain a supported rare earth nanocomposite catalyst, that is, hydrogen chloride oxidation catalyst type II. The circumferential crushing strength of the catalyst is 76.6N / cm, and the particle diameter of the supported active componen...

Embodiment 3

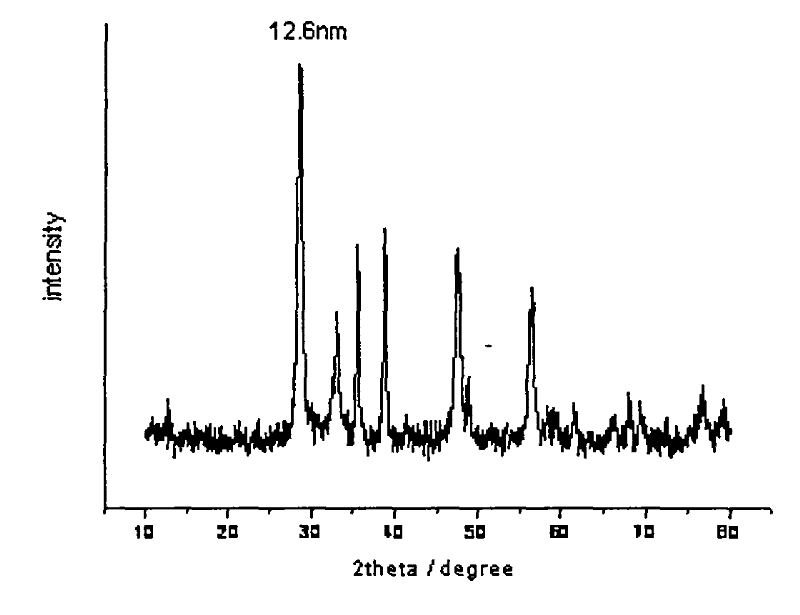

[0043] Example 3: Preparation and Application of Supported Rare Earth Nanocomposite Catalysts

[0044] Using the catalyst preparation method described in Example 2, the difference is that the carrier is replaced by silica to prepare a supported rare earth nanocomposite catalyst. 8 g of the above-mentioned catalysts were loaded into the fixed-bed reactor, and the conversion rate of hydrogen chloride was 84.3% under the condition that the volume flow ratio of hydrogen chloride to oxygen was 1.5:1 at normal pressure of 360°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com