Preparation method for slow-release-type nanometer zero-valent iron particles

A nano-zero-valent iron, slow-release technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of easy agglomeration, high equipment requirements, slow release, etc., to achieve good results Dispersion and reactivity, simple preparation process, long-term effective control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

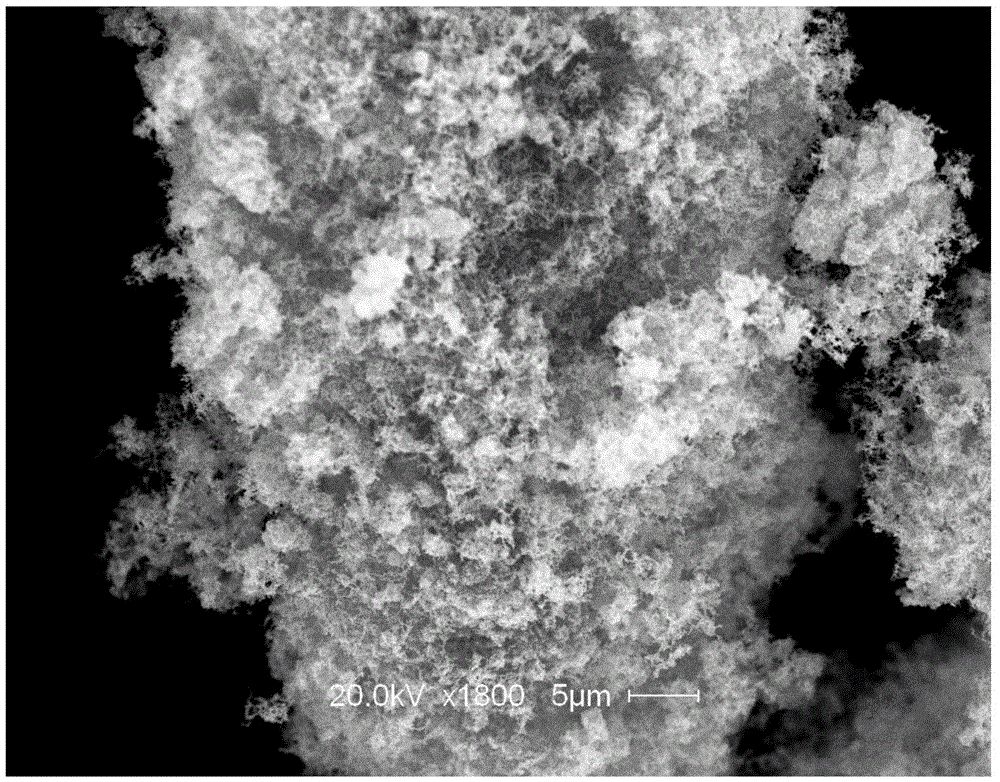

[0022] A method for preparing slow-release nano-sized zero-valent iron particles. The material uses nano-sized zero-valent iron particles as the core and covers PASP on the surface. The specific preparation steps are as follows: add PASP particles with a molecular weight of 20,000 to deionized water , heated to make it fully dissolved, added deionized water to constant volume, and obtained a PASP solution with a mass fraction of 0.1%; weighed 0.5g of FeSO 4 ·7H 2 O is added in the described PASP solution of 50mL, mechanical stirring makes it fully mix, pass into nitrogen during the mixing process, remove the dissolved oxygen in the solution, obtain the mixed solution of ferrous sulfate / PASP; Weigh 0.4g of NaBH 4 Powder, added to the mixed solution of ferrous sulfate / PASP, 2mL of NaOH solution with a concentration of 0.5mol / L was added dropwise, mechanically stirred to make it fully mixed and reacted for 30min to obtain a nanometer zero-valent iron solution; the nanometer The ...

Embodiment 2

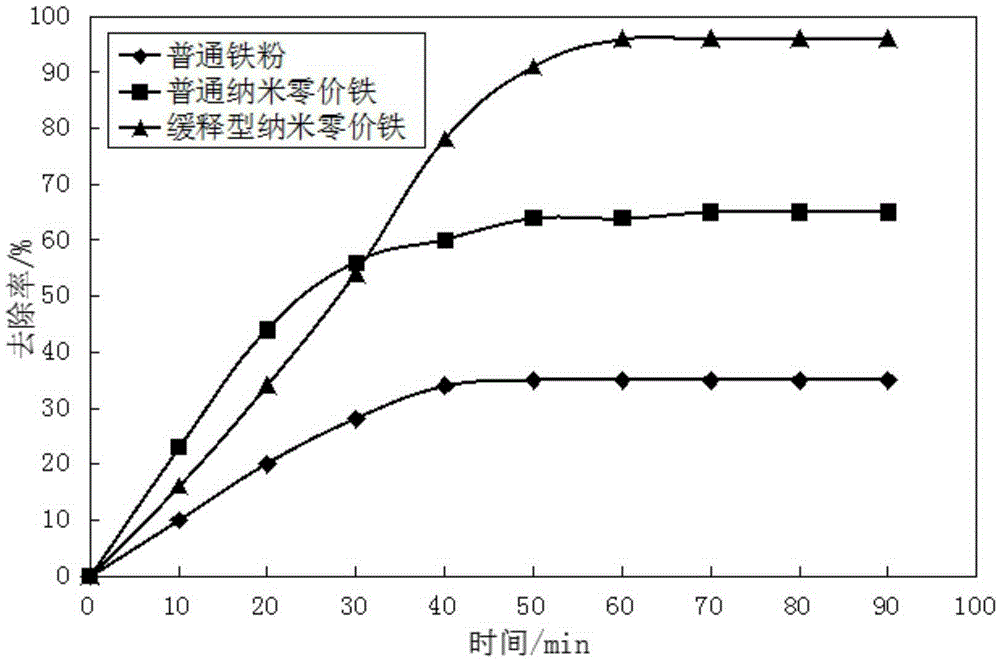

[0024] Cr 6+ The removal rate experiment. Get 0.5g of the nano zero-valent iron prepared by this patent and add it to 100mL of Cr 6+ In the simulated weakly acidic heavy metal polluted wastewater with a concentration of 100mg / L, put it in a constant temperature shaking box at 25°C for reaction, and use an ion electrode to measure Cr in the water at regular intervals. 6+ Concentration, to get the Cr of the material 6+ Remove curves.

Embodiment 3

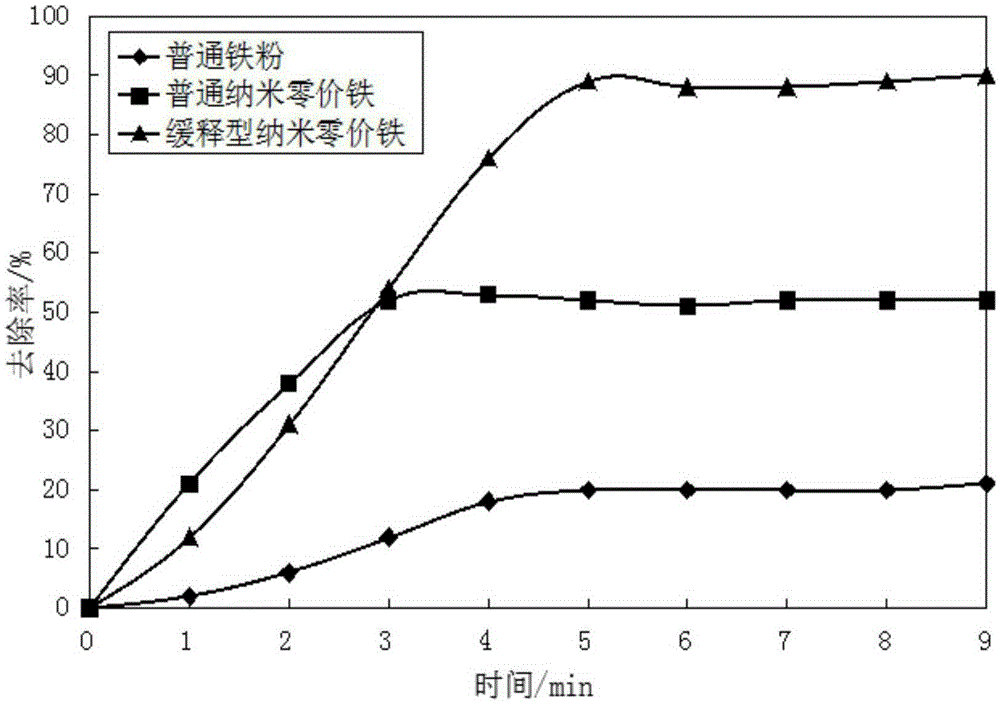

[0026] The nano zero-valent iron particles prepared by the present invention are subjected to the removal rate experiment of chlorobenzenes. Take 0.05g of the nanometer zero-valent iron prepared by this patent and add it to 150mL of simulated weakly acidic chlorobenzene polluted wastewater with a hexachlorobenzene concentration of 200 μg / L, and put it into a constant temperature oscillation box at 25°C for reaction. Samples are taken at regular intervals, the sample is extracted with n-hexane, and the concentration of hexachlorobenzene in the sample is measured by gas chromatography to obtain the hexachlorobenzene removal curve of the material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com