Nano-meta-material full-color-gamut palette

A metamaterial and palette technology, applied in the fields of nanophotonics and ion photonics, can solve the problems of non-adjustable color, affect color fastness, chemical instability of pigment substances, etc., and achieve precise adjustment of color output, color Environmentally friendly, pollution-free, colorful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

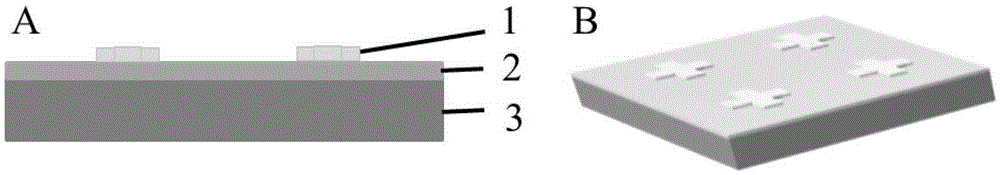

[0024] (1) thermal oxidation passivation layer: utilize thermal oxidation growth on the surface of silicon (Si) substrate 1 Thick SiO 2 as a passivation layer.

[0025] (2) Photolithography patterning: in Si / SiO 2AR-N7520.18 negative photoresist with a thickness of 100nm was spin-coated on the surface at a speed of 5000 revolutions per second, pre-baked in an oven at 85°C for 5 minutes, and the photoresist was subjected to an acceleration voltage of 80kV using a NanoBeam electron beam etching system. Expose, develop in tetramethylammonium hydroxide (TMAH) developing solution for 1 minute and rinse with deionized water to obtain an imaged nanostructure array;

[0026] (3) Dielectric layer formation: use silicon oxide as a mask, etch the silicon substrate with a reactive ion etching machine, the power of the etching machine is 400W, SF 6 and C 4 f 8 The flow rates were 40 and 90 sccm / min, respectively, and the etching time was 50 seconds. Due to the scallop effect of the e...

Embodiment 2

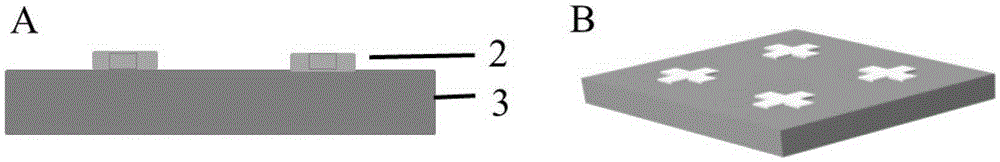

[0029] (1) Chemical vapor deposition mask layer: grown on the surface of silicon (Si) substrate by chemical vapor deposition (CVD) Thick SiO 2 as a mask layer.

[0030] (2) Photolithography patterning: in Si / SiO 2 AR-N7520.18 negative photoresist with a thickness of 100nm was spin-coated on the surface at a speed of 5000 revolutions per second, pre-baked in an oven at 85°C for 5 minutes, and the photoresist was subjected to an acceleration voltage of 80kV using a NanoBeam electron beam etching system. Expose, develop in tetramethylammonium hydroxide (TMAH) developing solution for 1 minute and rinse with deionized water to obtain an imaged nanostructure array;

[0031] (3) Dielectric layer formation: use photoresist and silicon oxide as a mask, and use a reactive ion etching machine to perform isotropic etching on the silicon substrate. The power of the etching machine is 400W, SF 6 and C 4 f 8 The flow rates are 40 and 90 sccm / min respectively, and the etching time is 50...

Embodiment 3

[0035] (1) Photolithographic patterning: Spin-coat AR-N7520.18 negative photoresist with a thickness of 100nm on the surface of the glass substrate at a speed of 5000 revolutions per second, pre-bake in an oven at 85°C for 5 minutes, and use NanoBeam The electron beam etching system exposes the photoresist with an accelerating voltage of 80kV, develops it in tetramethylammonium hydroxide (TMAH) developer solution for 1 minute, and rinses it with deionized water to obtain an imaged nanostructure array;

[0036] (2) Dielectric layer formation: using photoresist as a mask, use a reactive ion etching machine to etch the glass substrate isotropically, the power of the etching machine is 400W, SF 6 and C 4 f 8 The flow rates are 40 and 90 sccm / min, respectively, and the etching time is 50 seconds to form nanopillars with a height of 100nm and the suspended silicon nanostructure array supported by them;

[0037] (3) Metal-medium-metal three-dimensional structure: a 30nm gold nanola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com