Graphene-containing solar cell and preparation method thereof

A technology of solar cells and graphene, which is applied in the field of solar cells containing graphene and its preparation, can solve the problems of low manufacturing cost, achieve the effects of increasing conversion rate, improving conversion efficiency, and improving time stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

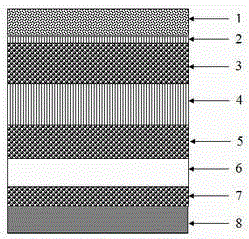

[0032] 1) Low-iron glass is used as the light-transmitting layer;

[0033] 2) Aluminum zinc oxide AZO conductive glass is used as the transparent electrode layer;

[0034] 3) Prepare a NiO layer on the surface of conductive glass by spraying thermal decomposition technology, with a thickness of 35nm;

[0035] 3) A mixed solution of nickel hexanoate acetone, lithium acetate, and magnesium acetate tetrahydrate was prepared according to the molar ratio of 1:1:3, spin-coated on the transition layer, and dried at 400°C to prepare the electron transport layer; thickness 64nm;

[0036] 4) Prepare light absorbing layer:

[0037] a. Prepare PbI2 solution, the concentration is 0.5Mol / L, and the solvent is dimethylformamide;

[0038]b. Prepare CH3NH3I solution: the concentration is 10 mg / mL, and the solvent is isopropanol;

[0039] In-situ synthesis of perovskite materials by solution method: spin-coat PbI2 solution on the electron transport layer first, dry it and soak it in CH3NH3I...

Embodiment 2

[0047] 1) Low-iron glass is used as the light-transmitting layer;

[0048] 2) Aluminum zinc oxide AZO conductive glass is used as the transparent electrode layer;

[0049] 3) Prepare a NiO layer on the surface of conductive glass by spraying thermal decomposition technology; the thickness is controlled at 15nm;

[0050] 4) According to the molar ratio of 2:1:3, a mixed solution of nickel acetone caproate, lithium acetate, and magnesium acetate tetrahydrate was prepared, spin-coated on the transition layer, and dried at 360°C to prepare the electron transport layer; thickness 53nm;

[0051] 5) Prepare light absorbing layer:

[0052] a. Prepare PbI2 solution, the concentration is 2.0Mol / L, and the solvent is dimethylformamide;

[0053] b. Prepare CH3NH3I solution: concentration 8mg / mL, solvent is isopropanol;

[0054] In-situ synthesis of perovskite materials by solution method: spin-coat PbI2 solution on the electron transport layer first, dry it and soak it in CH3NH3I solu...

Embodiment 3

[0064] 1) Low-iron glass is used as the light-transmitting layer;

[0065] 2) Use fluorine tin oxide (FTO, fluorinated opedtinoxide) conductive glass as the transparent electrode layer;

[0066] 3) Prepare a NiO2 layer on the surface of conductive glass by spraying thermal decomposition technology; the thickness is 50nm;

[0067] 4) According to the molar ratio of 1:1:10, a mixed solution of nickel acetone hexanoate, lithium acetate, and magnesium acetate tetrahydrate was prepared, spin-coated on the transition layer, and dried at 350°C to prepare the electron transport layer; thickness 99nm;

[0068] 5) Prepare light absorbing layer:

[0069] a. prepare PbI2 solution, concentration is 2.3Mol / L, and solvent is dimethylformamide;

[0070] b. Prepare CH3NH3I solution: the concentration is 7.5mg / mL, and the solvent is isopropanol;

[0071] In-situ synthesis of perovskite materials by solution method: spin-coat PbI2 solution on the electron transport layer first, dry it and so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com