Hydrogenation and dehydrogenation furnace and preparation method of low-oxygen-content titanium powder

A technology for hydrogenation and dehydrogenation and titanium powder is applied in the field of hydrogenation and dehydrogenation furnace and the preparation of titanium powder with low oxygen content. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

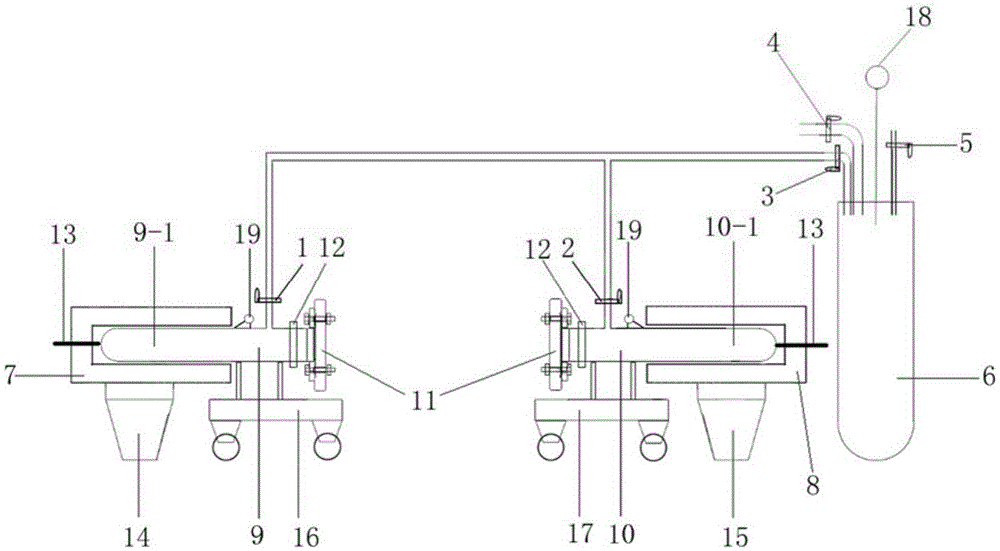

[0045] In this embodiment, the structure of the hydrodehydrogenation furnace is as figure 1 As shown, it includes a horizontally placed heating furnace, a horizontally placed reactor, a gas storage tank 6, a first support 14, a second support 15, a movable third support 16 and a movable fourth support 17, the The heating furnace comprises a first heating furnace 7 and a second heating furnace 8, and the reactor comprises a first reactor 9 and a second reactor 10,

[0046] The first heating furnace 7 and the second heating furnace 8 are equipped with thermocouples 13, and the first reactor 9 and the second reactor 10 are cylinders with both ends closed, and one end of the cylinder is provided with a material Inlet and outlet, there is a sealing cover 11 at the material inlet and outlet, and a water cooling jacket 12 is provided on the cylinder close to the sealing cover. The water cooling jacket is used to reduce the temperature at the sealing cover during the use of the reacto...

Embodiment 2

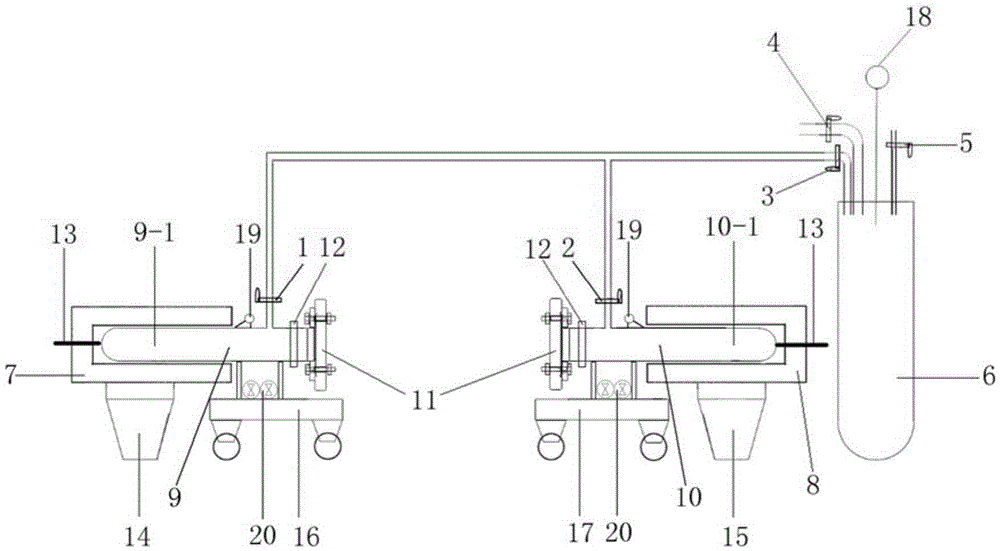

[0049] In this embodiment, the structure of the hydrodehydrogenation furnace is as figure 2 As shown, it includes a horizontally placed heating furnace and a horizontally placed reactor, a gas storage tank 6, a first support 14, a second support 15, a movable third support 16, a mobile fourth support 17 and a fan 20 , the heating furnace comprises a first heating furnace 7 and a second heating furnace 8, and the reactor comprises a first reactor 9 and a second reactor 10,

[0050] The first heating furnace 7 and the second heating furnace 8 are equipped with thermocouples 13, and the first reactor 9 and the second reactor 10 are cylinders with both ends closed, and one end of the cylinder is provided with a material Inlet and outlet, there is a sealing cover 11 at the material inlet and outlet, and a water cooling jacket 12 is provided on the cylinder close to the sealing cover. The water cooling jacket is used to reduce the temperature at the sealing cover during the use of ...

Embodiment 3

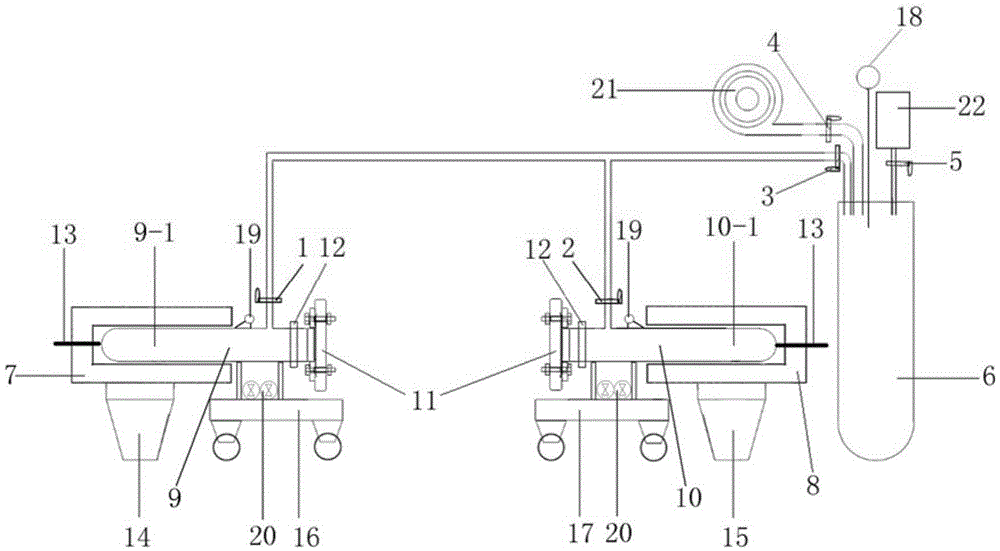

[0053] The present embodiment improves the preparation method of low oxygen content titanium powder, as image 3 As shown, the method uses the hydrodehydrogenation furnace described in Example 2 and is equipped with a vacuum pump 21 and a storage tank 22 storing high-purity hydrogen, and the vacuum pump 21 and the storage tank 22 storing high-purity hydrogen are respectively connected with the hydrogenation dehydrogenation furnace through pipe fittings. The vacuum joint of the gas storage tank 6 of the hydrogen furnace is connected with the hydrogen source joint, and the steps are as follows:

[0054] ① Loading

[0055] The hydrogen storage alloy vanadium titanium chromium iron is placed in the reaction section 9-1 of the first reactor, and the 0-grade sponge titanium with a particle size of no more than 25 mm is placed in the reaction section 10-1 of the second reactor. The mass ratio of hydrogen alloy vanadium-titanium-chromium-iron to 0-grade sponge titanium is 2:1, close ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com