Shell material of electronic equipment and preparation method thereof

A technology for shell materials and electronic equipment, applied in the field of materials, can solve problems such as reduced strength, high cost, and low linear expansion coefficient, and achieve the effects of improving environmental adaptability, solving shell cracks and deformation, and reducing thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

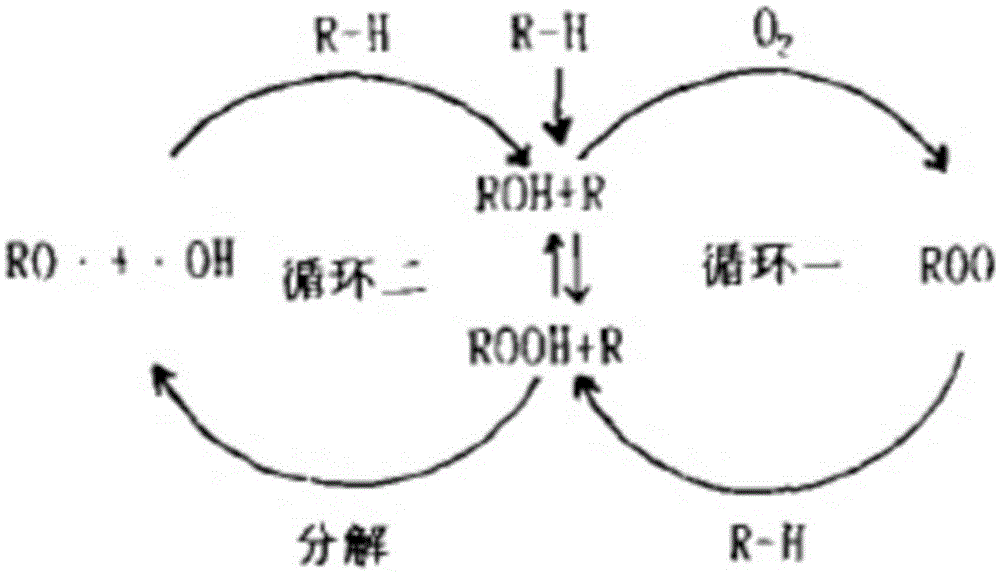

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the shell material is:

[0029] 1) Put glass fiber, HIPS and lubricant into a high-speed mixer, stir evenly, then add flame retardant, antioxidant and carbon black powder in turn, and stir evenly;

[0030] 2) Transfer the uniformly mixed materials above to the hopper of the twin-screw extruder, turn on the twin-screw extruder, and control the temperatures of the front, middle, rear and head of the barrel to 165-170°C, 180-190°C, 195-205°C, 210-230°C, wherein the head screw speed is controlled at 200-230rpm / min, extruded to obtain molten material;

[0031] 3) The above molten material is water-cooled, pelletized, sieved, and dried to obtain the HIPS composite shell material of the present invention.

[0032] The flame retardant is one or a mixture of bisphenol A-bis(diphenyl phosphate) (BDP), decabromodiphenylethane, antimony trioxide and bromotriazine.

[0033] The antioxidant is tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pen...

Embodiment 1

[0035]The shell material of an electronic device of the present invention has the following components and parts by weight: 70 parts of polystyrene, 20 parts of glass fiber, 5 parts of flame retardant, 5 parts of antioxidant, and 1 part of paraffin wax as lubricant. The flame retardant includes 1 part of BDP, 2 parts of antimony trioxide and 2 parts of bromotriazine; the antioxidant includes 2 parts of (antioxidant 1010), 1 part of (antioxidant 1076) and (antioxidant 168) 2 servings.

[0036] The preparation method is to put glass fiber, HIPS and lubricant into a high-speed mixer, stir evenly, then add flame retardant system and antioxidant in turn, and stir evenly. Transfer the uniformly mixed material above to the hopper of the twin-screw extruder, turn on the twin-screw extruder, and control the temperatures of the front, middle, rear and head of the barrel to 168°C, 185°C, and 200°C respectively. ℃, 220℃, wherein the head screw speed is controlled at 220rpm / min; the molte...

Embodiment 2

[0038] A shell material for electronic equipment of the present invention, its components and parts by weight are: 80 parts of polystyrene, 10 parts of glass fiber, 8 parts of flame retardant, 4 parts of antioxidant, and the lubricant is polyethylene wax and stearin There are 2 parts of the mixture of acid zinc and 1 part of carbon black powder. The flame retardant includes 5 parts of BDP and 3 parts of bromotriazine; the antioxidant includes 0.5 parts of (antioxidant 1010), 2 parts of (antioxidant 1076) and 1.5 parts of (antioxidant 168).

[0039] The preparation method is to put glass fiber, HIPS and lubricant into a high-speed mixer, stir evenly, then add flame retardant system, antioxidant and carbon black powder in sequence, and stir evenly. Transfer the uniformly mixed material above to the hopper of the twin-screw extruder, turn on the twin-screw extruder, and control the temperatures of the front, middle, rear and head of the barrel to 165°C, 180°C, and 195°C respectiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com