Ganoderic acid high-producing engineering strain kmust-VGB-1

A technology for engineering strains and ganoderma lucidum acid, applied in the fields of genetic engineering and metabolic engineering, can solve the problem of low production of ganoderma lucidum acid, and achieve the effects of saving labor, shortening production cycle, and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

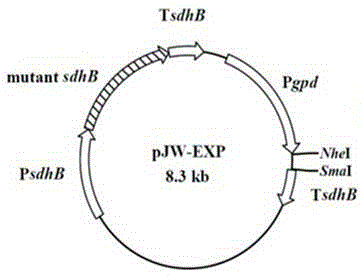

[0046] Embodiment 1: Construction of pJW-EXP vector

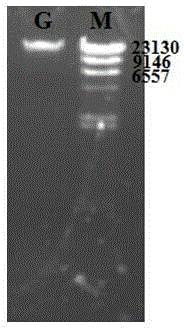

[0047] 1. Extraction of Ganoderma lucidum genomic DNA

[0048] Weigh about 0.2 g of mycelium of freeze-dried wild-type Ganoderma lucidum (CCGMC5.0616), grind it into powder in liquid nitrogen, and transfer the powder into 1.5 mL of CTAB (cetyltrimethyl bromide) preheated at 65 °C. Ammonium) in the extraction buffer, keep warm at 65°C for 30min, then centrifuge at 10,000g for 20min at 4°C, take the supernatant and add an equal volume of chloroform:isoamyl alcohol (24:1) mixture, shake gently for more than 30min, Centrifuge at 10,000g for 20min at 4°C; transfer the supernatant into a 1.5mL centrifuge tube, add 2 / 3 volume of isopropanol pre-cooled at -20°C, shake gently for 5min, remove the DNA with a glass rod, and use 75 % ethanol was washed 2-3 times, dried at room temperature, dissolved in an appropriate amount of TE containing 20 μg / mL RNase, digested RNA at 37°C for 30 min, and then the genomic DNA of Ganoderma lucidu...

Embodiment 2

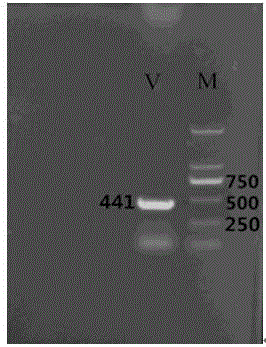

[0072] Example 2: Construction of pJW-EXP-tVGB vector

[0074]Using the plasmid PUC8:16 provided by Professor B.C. Stark of the IIT Center Illinois Institute of Technology in Chicago, USA, the gene of Vitiligo hyaline hemoglobin was cloned (the primers used were VGB-Nhe-F and VGB-Sma-R), and the primers

[0075] VGB-Nhe-F: 5'-GCTAGCCTAGCTAGCATGTTAGACCAACAAACCGT-3'

[0076] VGB-Sma-R: 5'-GGGCCCGATTTGTACGCTCAAGACGCTGAATAAGA-3'

[0077] Perform PCR to obtain the VGB gene, the nucleotide sequence of which is shown in SEQ ID NO: 1, encoding Vitreum hyaline hemoglobin shown in SEQ ID NO: 2; the PCR conditions are: 95°C for 10min, 95°C for 30s, 60°C for 30s, and 72°C for 30s , 72℃10min (see image 3 ).

[0078] 2. Insert the VGB gene into the pJW-EXP vector

[0079] The pJW-EXP vector was double-digested with SmaI and NheI, and the digested fragment was recovered. Using T4 ligase at 16°C, the VGB gene was inserted between the NheI and SmaI of th...

Embodiment 3

[0080] Example 3: Transformation of pJW-EXP-tVGB into wild-type Ganoderma lucidum cells by PEG-mediated protoplast fusion

[0081] 1. Preparation and transformation of Ganoderma lucidum protoplasts

[0082] First, wild-type Ganoderma lucidum mycelium was prepared into protoplasts with lysozyme, and then Ganoderma lucidum protoplasts were suspended in 100 μL of STC (0.55M sorbitol, 10 mM CaCl 2 , 10mM Tris-HCl buffer, pH 7.5), then add 1 μg of plasmid DNA and PTC buffer (60% PEG4000 (W / V), 10mM Tris-HCl buffer, pH 7.5, 50mM CaCl 2 ); incubate on ice for 10 min, then add 1 mL of PTC buffer, mix well and incubate at room temperature for 20 min; use 10 mL of melted CYM solid medium to mix with transformed protoplasts, pour the plate and add carboxin to make the final concentration of carboxin 2 mg / L; Several single colonies can grow after cultured at 30°C for 10 days.

[0083] 2. Subculture on plates containing carboxin resistance

[0084] Transfer a single colony to a CYM ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com