Titanium dioxide-coated lithium-sulfur battery positive electrode material and preparation method thereof

A cathode material, titanium dioxide technology, applied in the preparation of cathode materials for lithium-sulfur batteries, in the field of cathode materials for lithium-sulfur batteries coated with titanium dioxide, can solve the problems of irreversible loss of positive active materials, low electronic conductivity, and reduced battery capacity, etc., to achieve Effects of reduced shuttle effect, discharge specific capacity, and improved cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

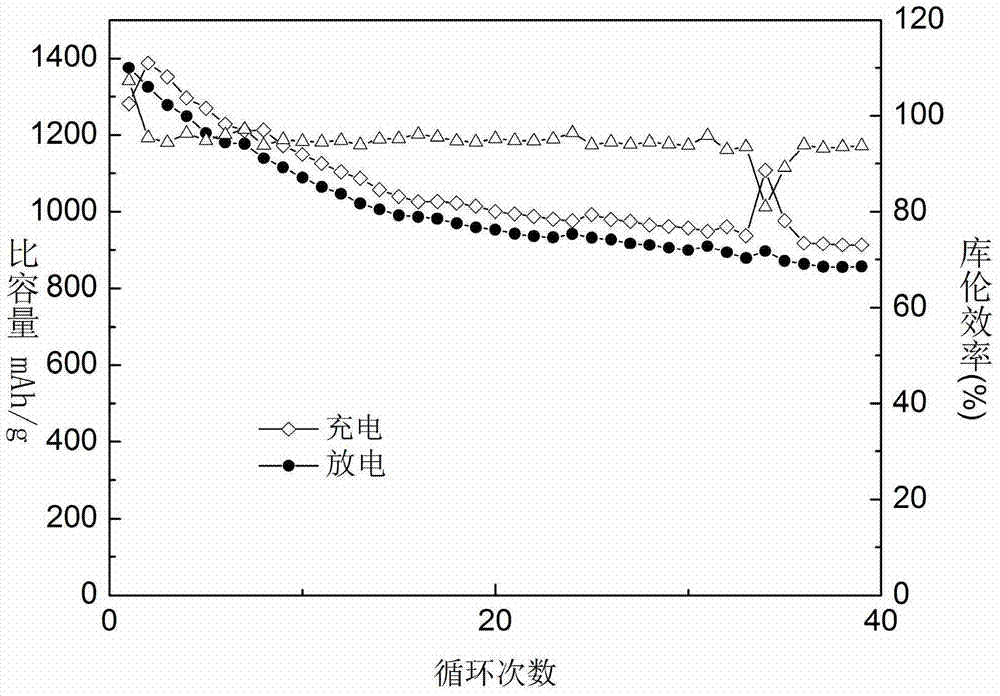

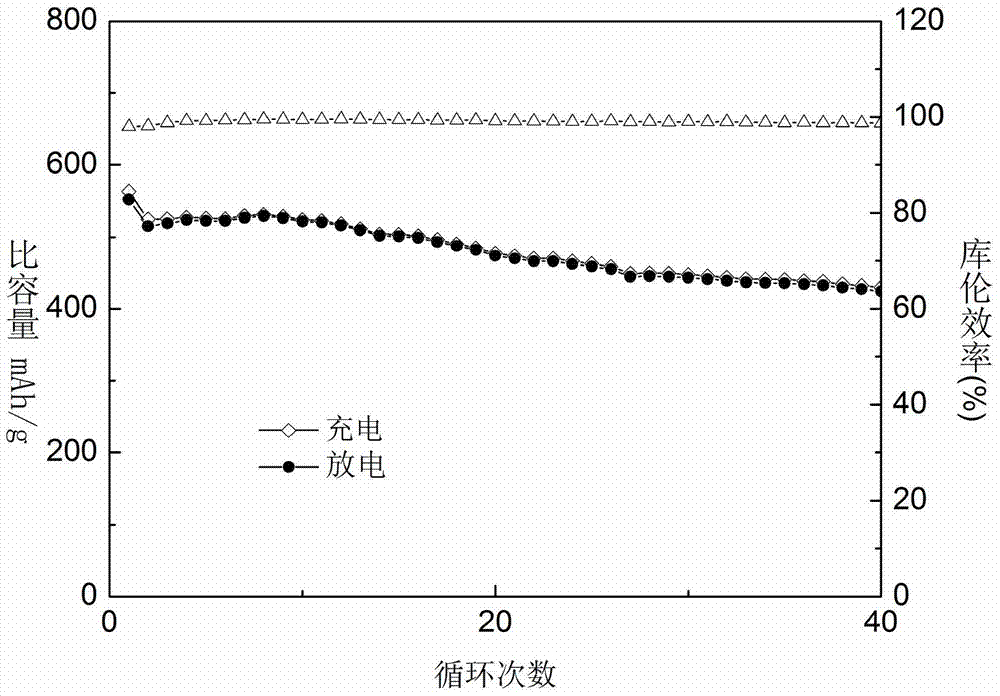

[0022] Take the sublimated sulfur of the size of carbon fiber cloth of the positive electrode material and put it in a graphite crucible, cover it with a layer of carbon fiber cloth, and compact it with a heavy object. Put it in a tube furnace, heat the crucible to 155°C in a nitrogen atmosphere, and keep it warm for 6 hours to sublimate the sulfur. Under the adsorption of the micropores on the carbon fiber cloth, the sulfur is attached to the carbon fiber cloth, and a carbon fiber cloth with good S coating is obtained.

[0023] 98% TiCl 4 The solution was diluted to a 5% ethanol solution, and further diluted to a 2% dilute solution with a mass fraction of water.

[0024] The prepared sulfur-containing carbon fiber cloth was made into the size of a battery pole piece and placed in 2% TiCl 4 After 0.5h in the aqueous solution, take it out, wash and dry, and obtain a titanium dioxide-coated lithium-sulfur battery positive electrode material. The battery is then assembled and t...

Embodiment 2

[0026] Take the sublimated sulfur of the size of carbon fiber cloth of the positive electrode material and put it in a graphite crucible, cover it with a layer of carbon fiber cloth, and compact it with a heavy object. Put it in a tube furnace, heat the crucible to 155°C in a nitrogen atmosphere, and keep it warm for 7 hours to sublimate the sulfur. Under the adsorption of the micropores on the carbon fiber cloth, the sulfur is attached to the carbon fiber cloth, and a carbon fiber cloth with good S coating is obtained.

[0027] 98% TiCl 4 The solution was diluted to a 5% mass fraction of an ice-water solution, and further diluted with water to a 2% mass fraction of a dilute solution.

[0028] The prepared sulfur-containing carbon fiber cloth was made into the size of a battery pole piece and placed in 2% TiCl 4 In the aqueous solution, take it out after 3 hours, wash and dry, and obtain the titanium dioxide-coated lithium-sulfur battery positive electrode material. The batt...

Embodiment 3

[0030]Take the sublimated sulfur of the size of carbon fiber cloth of the positive electrode material and put it in a graphite crucible, cover it with a layer of carbon fiber cloth, and compact it with a heavy object. Put it in a tube furnace, heat the crucible to 155°C in a nitrogen atmosphere, and keep it warm for 9 hours to sublimate the sulfur. Under the adsorption of the micropores on the carbon fiber cloth, the sulfur is attached to the carbon fiber cloth, and a carbon fiber cloth with good S coating is obtained.

[0031] Keep the temperature at 0℃~10℃ under the condition of ice water bath, add ice water to dilute 98% TiCl 4 solution to a solution with a mass fraction of 50%.

[0032] The carbon fiber cloth after absorbing sulfur was put into the solution, vigorously stirred for 10 minutes, washed and dried, and a titanium dioxide-coated lithium-sulfur battery positive electrode material was obtained. The battery is then assembled and tested. Scanning electron microsco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com