Novel composite material, and polymer coating material precursor produced using same

A composite material and polymer technology, applied in the direction of natural resin coating, coating, etc., can solve the problems of preparation cost, unconfirmed applicability of thermosetting resin, troublesome time, etc., and achieve the effect of firm bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

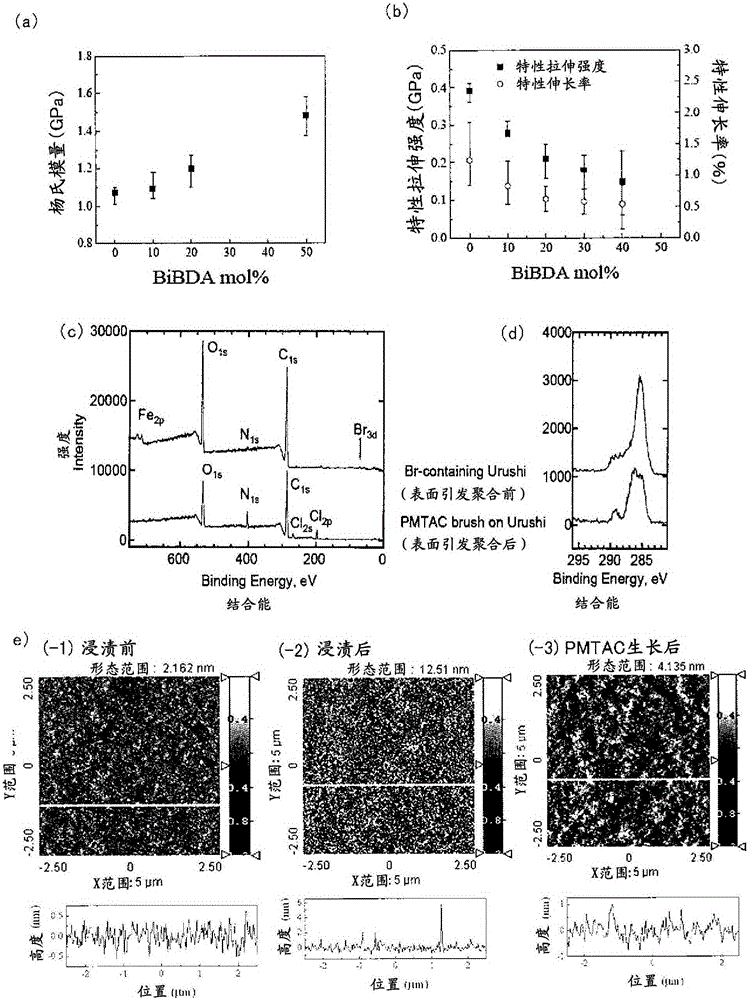

[0108] Compounds having a polymerization initiation site containing a halogen group (IA 1 -SP 1 -PI 1 ) synthesis (1)

[0109] As a compound having a polymerization initiation site containing a halogen group (IA 1 -SP 1 -PI 1 ) to synthesize 4-(2-(2-bromoisobutyryl)aminoethyl)benzene-1,2-diol (BiBDA) represented by formula (IV) in which X is a bromine atom (Br).

[0110] First, dopamine hydrochloride (2.0 g, 10.5 mmol) was put into 20 ml of methanol to obtain a cloudy suspension. A clear solution was obtained by adding 1.46 ml of triethylamine (10.5 mmol) thereto. After the solution was cooled to 0° C., a THF solution (2 ml) of 2-bromoisobutyryl bromide (1.3 ml; 10.5 mmol) and a methanol solution of triethylamine (2.19 ml: 15.8 mmol) were alternately added a small amount at a time ( 2ml). At this point, the pH of the solution was maintained at 9. Thereafter, the solution was warmed to room temperature and stirred for 1 hour. Next, a crude product of the target compou...

Embodiment 2

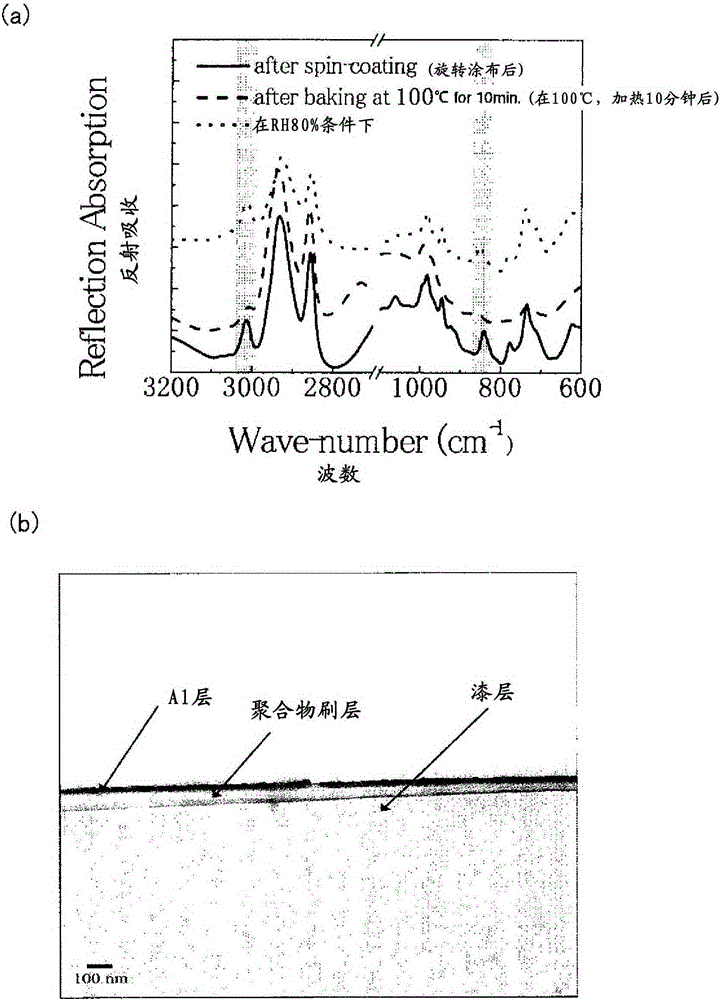

[0112] Production of polymer coating precursor containing polymerization initiator

[0113] As urushiol, a group in which R in the above formula (III) is represented by the above (iii) is used. First, iron (II) acetate (0.75 mmol) was mixed with ethanol dilute solution of urushiol (1.2 mmol), and the solution changed from brown to black at this time. Next, the bromine group-containing catechol compound (0.3 mmol) synthesized in Example 1 was added to this urushiol. The obtained mixed solution was subjected to ultrasonic homogenizer (Branson Sonifier ultrasonic cell disruptors) treatment. The obtained solution was coated (applied) on a silicon substrate as a base material by a spin coating method (3000 rpm) to form a thin film. Thereafter, a coating film having a thickness of about 1 micron was obtained by heating at 100° C. for 10 minutes. The thickness of the coating film was observed with an atomic force microscope (AFM) and measured using an Agilent 5500 microscope manuf...

Embodiment 3

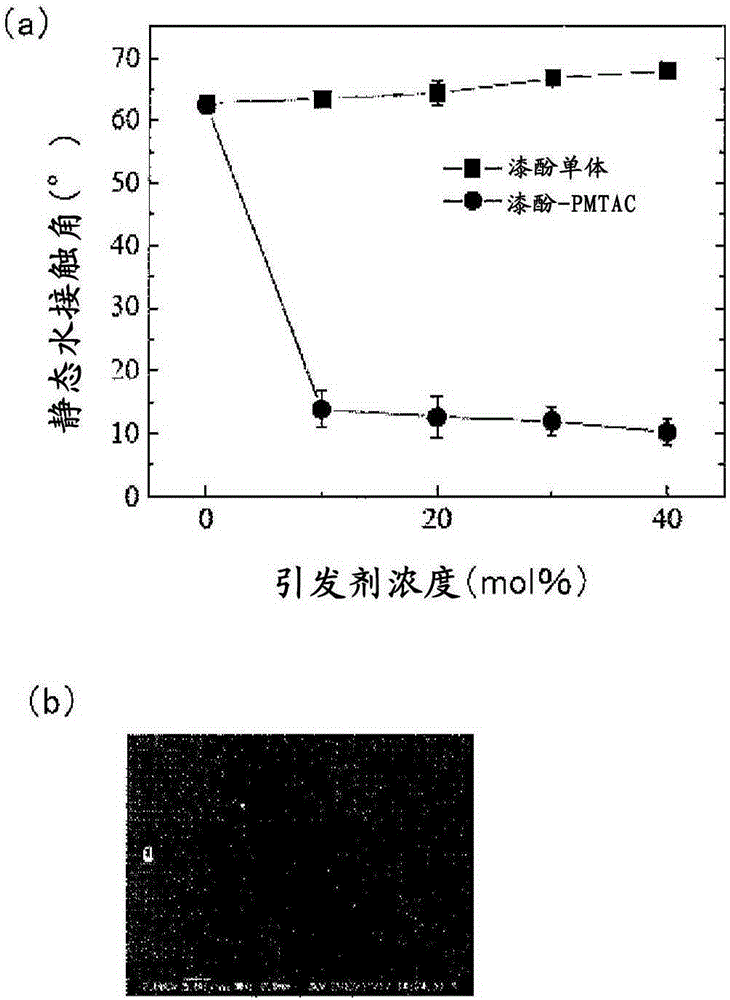

[0142] Production of polymer coating materials (surface modification materials)

[0143] Using the cured film (polymer coating material precursor) produced in Example 2, the 2-(methacryloyl group represented by the above formula (V) is carried out using the bromine group contained in the cured film as a polymerization initiation point. ) The surface of ethyltrimethylammonium chloride (MTAC) initiates polymerization, and the polymer electrolyte (PMTAC) as the polymer is grafted on the surface of the cured film.

[0144] This precursor, 0.1 mmol of CuBr, and further 4,4-dimethyl-2,2-bipyridine (0.2 mmol) were placed in a flask, and replacement with argon and degassing were alternately repeated three times. Thereafter, a 1.01M methanol solution of MTAC polymer was added, and argon replacement and degassing were alternately repeated three times. Polymerization was then performed at 30°C under argon substitution. After 12 hours, the reaction was stopped by exposing the solution t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com