Antimicrobial coating composition, medical implant material containing antimicrobial coating and preparation method of medical implant material

A technology for antibacterial coatings and implant materials, applied in coatings, medical science, prostheses, etc., can solve problems such as human toxicity, and achieve the effects of reduced biological toxicity, low manufacturing cost, and strong coating adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] Further, the preparation method comprises the following steps:

[0041] S1: immersing the substrate of the implant material in an aqueous solution of mussel adhesion protein, cleaning and drying to obtain a substrate containing a film layer of mussel adhesion protein;

[0042] S2: immerse the base material obtained in step S1 in a silver ion solution, wash and dry.

[0043]In step S1, the concentration and immersion time of the mussel adhesive protein aqueous solution can be adjusted according to the required protein film layer. In a preferred embodiment of the present invention, the concentration of the mussel adhesive protein aqueous solution can be 0.05-5mg / ml , the soaking time can be 5-120 minutes.

[0044] In step S1, the pH value of the mussel adhesion protein aqueous solution can be acidic or alkaline, and the preferred pH value is 3.0-9.0, which can be adjusted to the required pH value by commonly used dilute acid, dilute alkali solution or buffer solution. p...

Embodiment 1

[0050] Embodiment 1 contains the preparation of the metal titanium sheet of antibacterial coating

[0051] (1) Prepare Mefp-1 aqueous solution, adjust protein concentration to 0.5 mg / ml, and pH value to 4.0. Soak a clean titanium sheet (purity>99%) in the Mefp-1 aqueous solution for 2 hours, take out the titanium sheet, wash and dry it, and obtain a titanium sheet loaded with a Mefp-1 protein film layer.

[0052] (2) After immersing the titanium sheet loaded with the Mefp-1 protein film layer in 0.01M silver nitrate solution for 6h, take it out, clean it ultrasonically and dry it, that is, evenly distributed mussel adhesion protein / nano Silver particle antibacterial coating, the coating thickness is about 30nm.

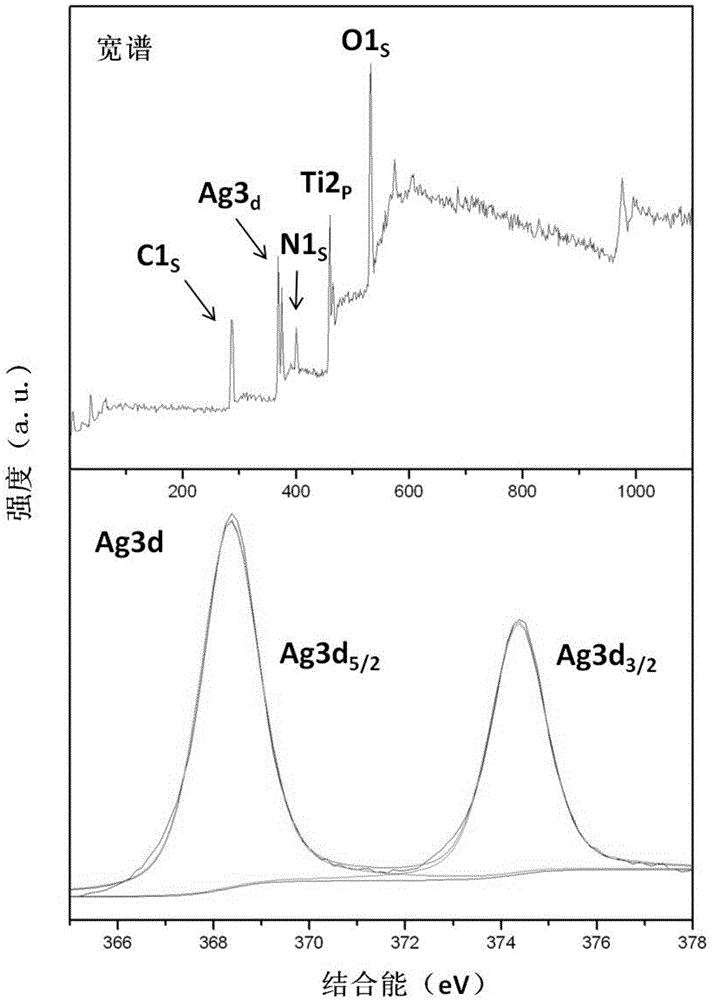

[0053] The X-ray photoelectron energy spectrogram of the titanium sheet that gained contains antibacterial coating is as figure 1 As shown, it indicates that mussel adhesion protein components and elemental silver exist on the surface of the titanium sheet.

[0054...

Embodiment 2

[0055] Embodiment 2 Preparation of titanium alloy sheet containing antibacterial coating

[0056] (1) Prepare Mefp-2 aqueous solution, adjust protein concentration to 1 mg / ml, and pH value to 6.0. The clean titanium alloy sheet (Ti6Al4V) was immersed in the Mefp-2 aqueous solution for 1 h, the titanium alloy sheet was taken out, washed and dried, and the titanium alloy sheet loaded with the Mefp-2 protein film layer was obtained.

[0057] (2) Immerse the titanium alloy sheet loaded with the Mefp-2 protein film layer in a 0.005M silver nitrate solution for 8 hours, take it out, clean it ultrasonically and dry it, so that evenly distributed mussel adhesion protein is obtained on the surface of the titanium alloy sheet / Nano silver particle antibacterial coating, the coating thickness is about 50nm.

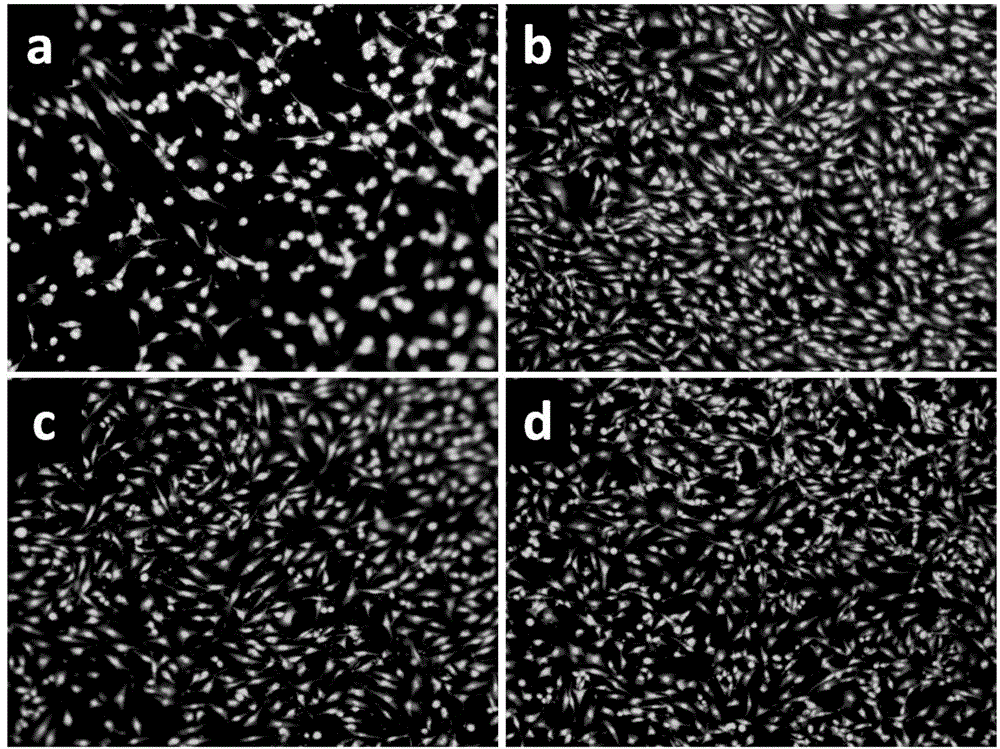

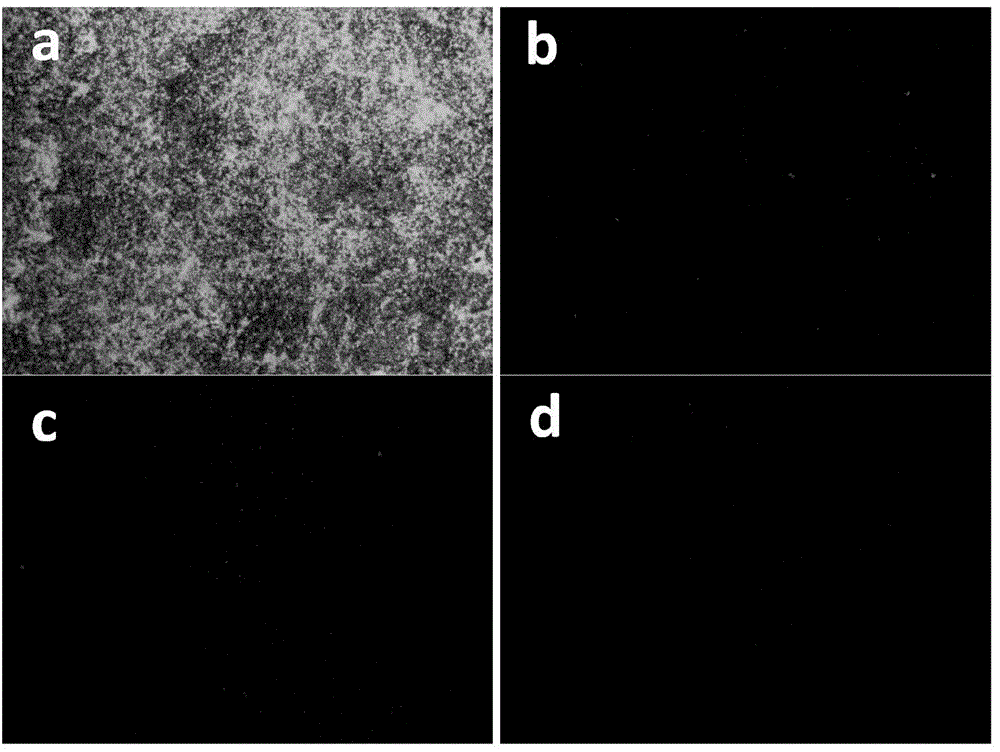

[0058] The obtained titanium alloy sheet containing antibacterial coating has good biocompatibility ( figure 2 c) and antibacterial properties ( image 3 c. Figure 4 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com