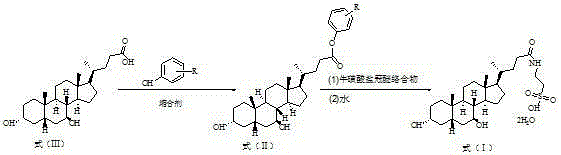

Preparing method for tauro ursodesoxy cholic acid

A technology of tauroursodeoxycholic acid and ursodeoxycholic acid, which is applied in the field of preparation of tauroursodeoxycholic acid, can solve the problems of inapplicability to industrial production, low purity of crude products, inconvenient use, etc., and achieve The effect of low cost, simple operation and post-processing, and increased controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

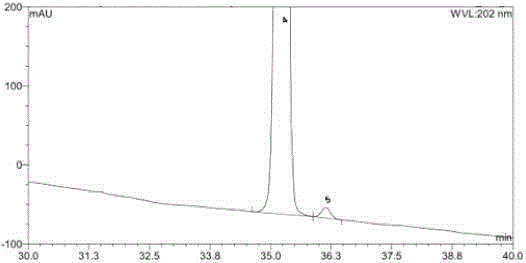

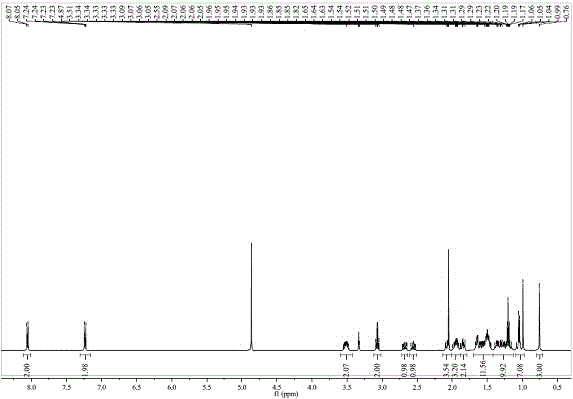

Examples

Embodiment 1

[0040] Preparation of Taurate Complex

[0041] At room temperature, dissolve 100.00 g (0.61 mol) of potassium taurine in water, then add complexing agent 18-crown-6161.92 g, and stir to dissolve. The above clear liquid was concentrated at 60°C to obtain 260.59 g of potassium taurate 18-crown-6 complex as a white solid.

Embodiment 2

[0043] Preparation of Taurate Complex

[0044] At room temperature, dissolve 100.00 g (0.68 mol) of sodium taurine in water, then add complexing agent 15-crown-5149.53 g, and stir to dissolve. The above clear liquid was concentrated at 60°C to obtain 248.52 g of sodium taurate 15-crown-5 complex as a white solid.

Embodiment 3

[0046] Preparation of Tauroursodeoxycholic Acid

[0047] At room temperature, add 10.0 g (25.4 mmol) of ursodeoxycholic acid and 2.39 g (25.4 mmol) of phenol into 100 mL of dichloromethane, stir and cool down to 10-20°C. Add 5.25g (25.4mmol) of N,N'-dicyclohexylcarbodiimide solution in dichloromethane dropwise. After the dropwise addition, react at 5-20°C for 2 hours, filter to remove insoluble matter, and concentrate the filtrate to obtain a light yellow oil The product was 11.45g, and the yield was 96.0%.

[0048] The above oil was recrystallized from acetonitrile to obtain a white sticky substance, which was directly used in the next reaction.

[0049] At room temperature, 15.68 g (36.7 mmol) of potassium taurate 18-crown-6 complex and the above-mentioned oily substance were added to dichloromethane, and stirred. After reacting at room temperature for 5 hours, TLC (ethyl acetate:petroleum ether=1:1) monitored that the reaction was complete. Add 0.19 g of glacial acetic aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com