Star type polysulfone resin industrial synthesis method

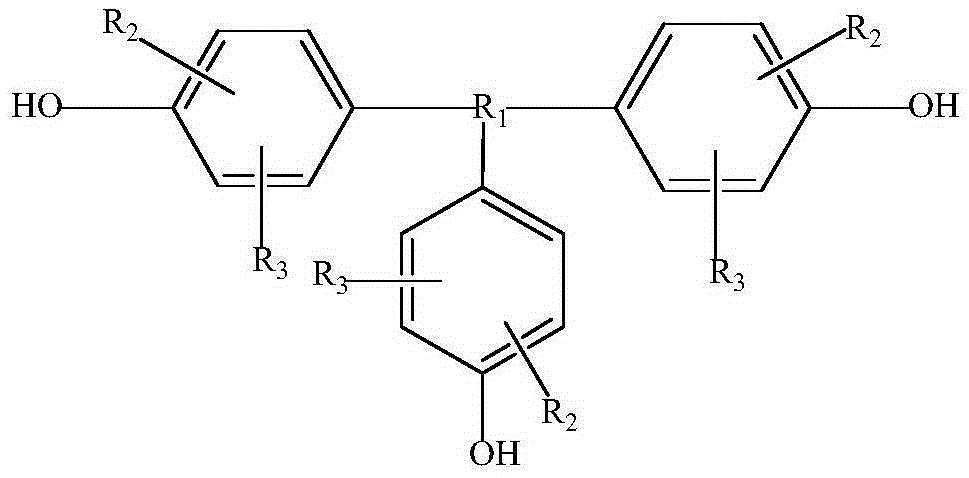

A polysulfone resin and a synthesis method technology are applied in the field of industrialized high-pressure synthesis of a new type of enhanced polysulfone resin, and can solve the problems of low light transmittance of polyethersulfone, shortened service life of plastics, and reduced impact strength of light-transmitting resins. , to achieve the effect of saving procurement costs, saving costs and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

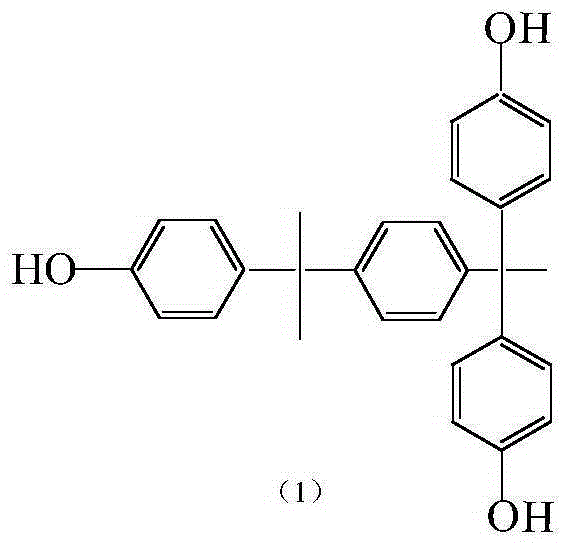

[0027] In a 300-liter stainless steel reaction kettle equipped with a nitrogen pipe, a condensing water separator and a high-efficiency stirrer, add 35.0kg of 4,4'-dichlorodiphenyl sulfone, 29.5kg of bisphenol A, and 14.0kg of sodium carbonate in sequence, and then add 100.00kg N,N'-dimethylacetamide. After pumping air to reduce the pressure inside the kettle to -0.09MPa, introduce nitrogen to raise the pressure inside the kettle to 0.01MPa, repeat this process five times to vacuumize and introduce nitrogen to replace the air in the kettle, and finally introduce nitrogen to reduce the pressure in the kettle to 0.01MPa. The pressure was raised to 2.0MPa. Heat to make the temperature in the kettle reach 170°C to form salt at constant temperature for 1 hour, then raise the temperature to 200°C for constant temperature polymerization for 3 hours, then add 200.4g of aromatic triphenols (1) to the system, increase the stirring speed to 80 rpm, continue Constant temperature for 0.5 ...

Embodiment 2

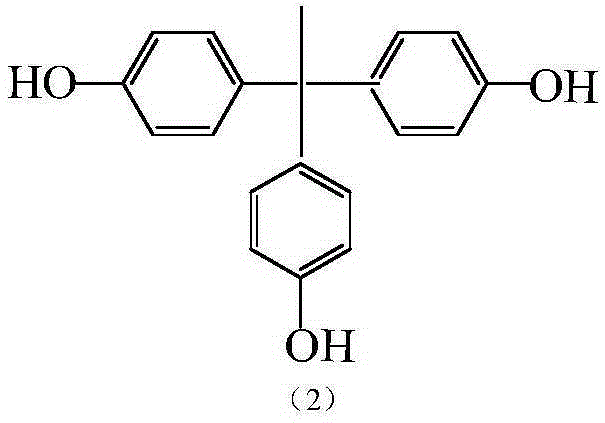

[0032] In a 300-liter stainless steel reaction kettle equipped with a nitrogen pipe, a condensing water separator and a high-efficiency stirrer, 35.0kg of 4,4'-dichlorodiphenyl sulfone, 32.32kg of bisphenol S, 14.0kg of sodium carbonate were added in sequence, and then 100.00kg N,N'-dimethylformamide. After pumping air to reduce the pressure inside the kettle to -0.09MPa, introduce nitrogen to raise the pressure inside the kettle to 0.01MPa, repeat this process five times to vacuumize and introduce nitrogen to replace the air in the kettle, and finally introduce nitrogen to reduce the pressure in the kettle to 0.01MPa. The pressure was raised to 3.0MPa. Heat to make the temperature in the kettle reach 200°C to form salt at constant temperature for 1 hour, then raise the temperature to 240°C for constant temperature polymerization for 3 hours, then add 144.6g of aromatic triphenols (2) to the system, increase the stirring speed to 80 rpm, Continue to keep the temperature const...

Embodiment 3

[0037]In a 300-liter stainless steel reaction kettle equipped with a nitrogen pipe, a condensate separator and a high-efficiency stirrer, 35.0kg 4,4'-dichlorodiphenyl sulfone, 24.05kg 4,4'-biquinone, and 14.0kg Sodium carbonate, then add 80.00kg N,N'-dimethylformamide. After pumping air to reduce the pressure inside the kettle to -0.09MPa, introduce nitrogen to raise the pressure inside the kettle to 0.01MPa, repeat this process five times to vacuumize and introduce nitrogen to replace the air in the kettle, and finally introduce nitrogen to reduce the pressure in the kettle to 0.01MPa. The pressure was raised to 3.0MPa. Heat to make the temperature in the kettle reach 200°C to form salt at constant temperature for 1 hour, then raise the temperature to 240°C for constant temperature polymerization for 3 hours, then add 144.6g of aromatic triphenols (3) to the system, increase the stirring speed to 80 rpm, Continue to keep the temperature constant for 0.5 to 1.0 hours until th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com