Hyaluronic acid-methyl cellulose composite hydrogel as well as preparation and application thereof

A technology of methyl cellulose and composite hydrogel, which is applied in the field of biomedical materials and tissue engineering, can solve problems such as lack of binding and controlled release of growth factors, non-degradable or poor degradation performance, and biocompatibility problems. Prolong the retention time in vivo, improve the mechanical properties, and have good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Under magnetic stirring (speed 300rpm), add 50mL of pre-prepared artificial cerebrospinal fluid into the Erlenmeyer flask, heat it to 90°C in a constant temperature oil bath, add 4g of sodium chloride to it; after it is completely dissolved, Add 11g of methylcellulose and continue heating; after the methylcellulose powder is evenly dispersed and completely wetted, take out the Erlenmeyer flask, add 50mL of artificial cerebrospinal fluid, place it in an ice-salt bath at -4°C, and stir at 200rpm for 40min , to obtain a methylcellulose solution, which was refrigerated overnight at 4°C.

[0034] (2) After 24 hours, slowly add 1 g of hyaluronic acid powder to the methylcellulose solution, stir to dissolve, and add 2 mL of 0.4 g / L PEG solution dropwise; adjust the pH to about 7.4 with 1M NaOH solution, Stirring was continued for 2 hours to obtain a gel-like substance; the substance was refrigerated overnight at 4° C., and subjected to vacuum freeze-drying to obtain a hyal...

Embodiment 2

[0041] (1) Under magnetic stirring (speed 300rpm), add 50mL of pre-prepared artificial cerebrospinal fluid into the Erlenmeyer flask, heat it to 90°C in a constant temperature oil bath, add 4g of sodium chloride to it; after it is completely dissolved, Add 9g of methylcellulose and continue heating; after the methylcellulose powder is evenly dispersed and completely wetted, take out the Erlenmeyer flask, add 50mL of artificial cerebrospinal fluid, place it in an ice-salt bath at -4°C, and stir at 200rpm for 40min , to obtain a methylcellulose solution, which was refrigerated overnight at 4°C.

[0042] (2) After 24 hours, slowly add 1 g of hyaluronic acid powder to the methylcellulose solution, stir to dissolve, add 2 mL of 0.4 g / LPEG solution dropwise; adjust the pH to about 7.4 with 1M NaOH solution, and continue stirring After 2 hours, a gel-like substance was obtained; the substance was refrigerated overnight at 4° C., and subjected to vacuum freeze-drying to obtain a hyalu...

Embodiment 3

[0045] (1) Under magnetic stirring (speed 300rpm), add 50mL of pre-prepared artificial cerebrospinal fluid into the Erlenmeyer flask, heat it to 90°C in a constant temperature oil bath, add 4g of sodium chloride to it; after it is completely dissolved, Add 5g of methylcellulose and continue heating; after the methylcellulose powder is evenly dispersed and completely wetted, take out the Erlenmeyer flask, add 50mL of artificial cerebrospinal fluid, place it in an ice-salt bath at -4°C, and stir at 200rpm for 40min , to obtain a methylcellulose solution, which was refrigerated overnight at 4°C.

[0046] (2) After 24 hours, slowly add 1 g of hyaluronic acid powder to the methylcellulose solution, stir to dissolve, add 2 mL of 0.4 g / LPEG solution dropwise; adjust the pH to about 7.4 with 1M NaOH solution, and continue stirring After 2 hours, a gel-like substance was obtained; the substance was refrigerated overnight at 4° C., and subjected to vacuum freeze-drying to obtain a hyalu...

PUM

| Property | Measurement | Unit |

|---|---|---|

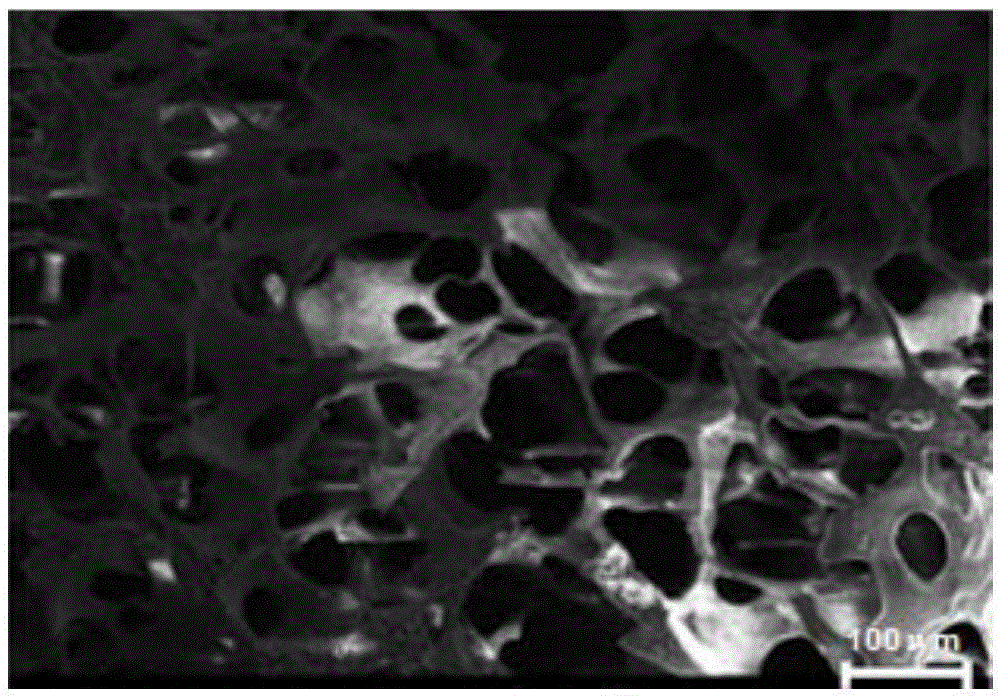

| Aperture | aaaaa | aaaaa |

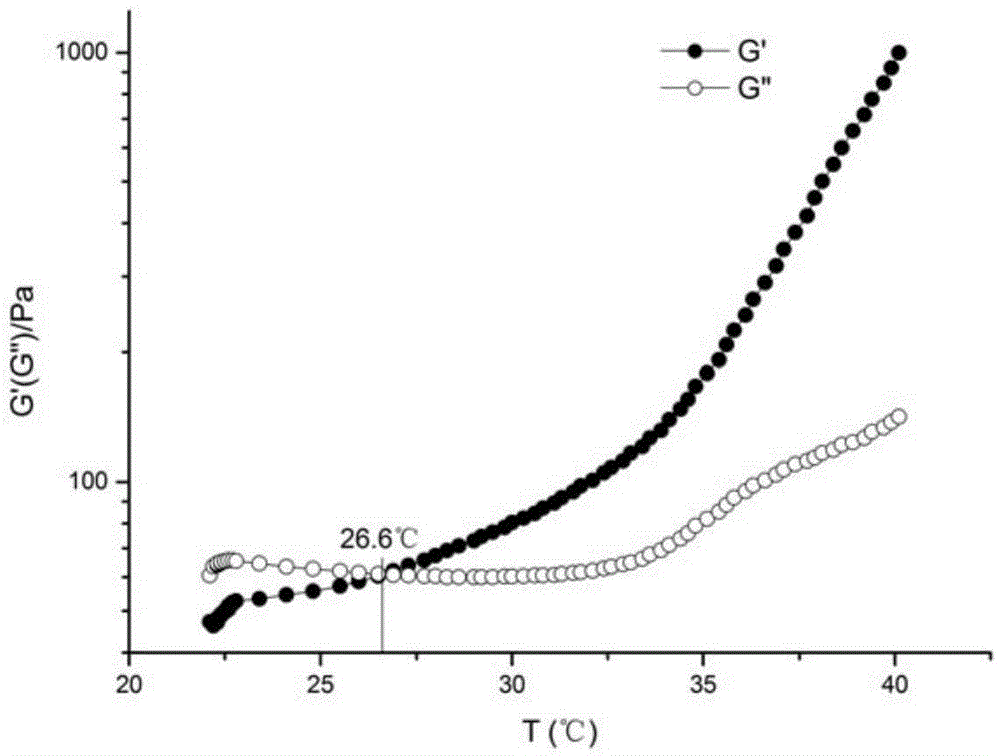

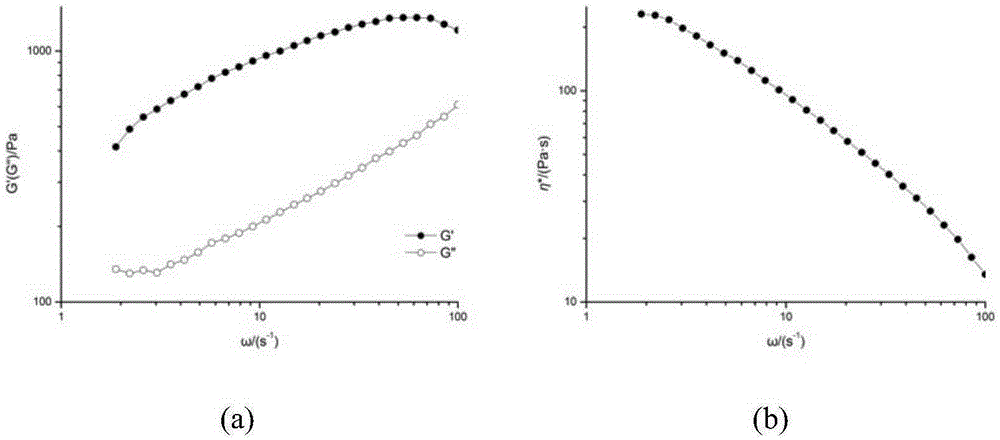

| Storage modulus | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com