Positive material for super capacitor, preparation method of positive material and super capacitor employing positive material

A technology for supercapacitors and positive electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, and can solve the problems of low life expectancy of specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043]The preparation method of the supercapacitor positive electrode of the present invention comprises the following five steps respectively: the first step is to make the electrode active material NiL 2 (H 2 O) 4 , conductive agent and binder are mixed in a beaker according to the mass ratio of 75:20:5; the second step is to add absolute ethanol to the above beaker, so that the absolute ethanol is immersed in the beaker; the third step is to put the above beaker Place on a magnetic heating stirrer and stir for 1 hour; the fourth step is to use a scraper to coat the material in the beaker on the positive electrode current collector; the last step is to place the coated positive electrode current collector in an electric heating constant temperature blast drying oven, Place at constant temperature at 100°C for 1 hour.

[0044] In the supercapacitor of the present invention, the electrolytic solution is KOH or NAOH with a concentration of 6 mol / liter.

[0045] The specific ...

Embodiment 1

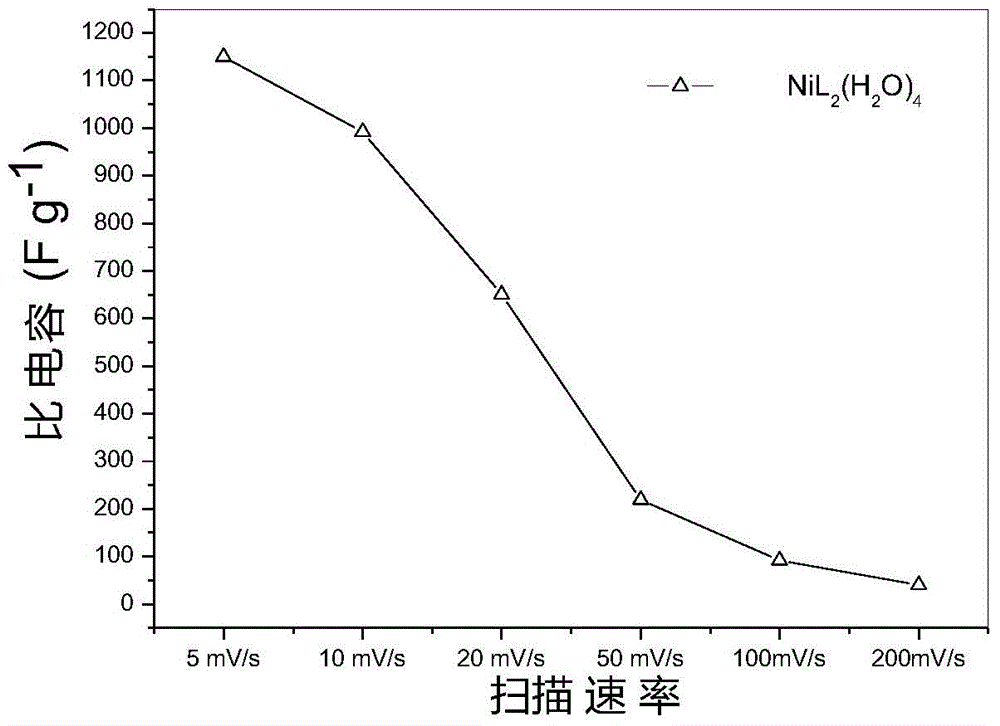

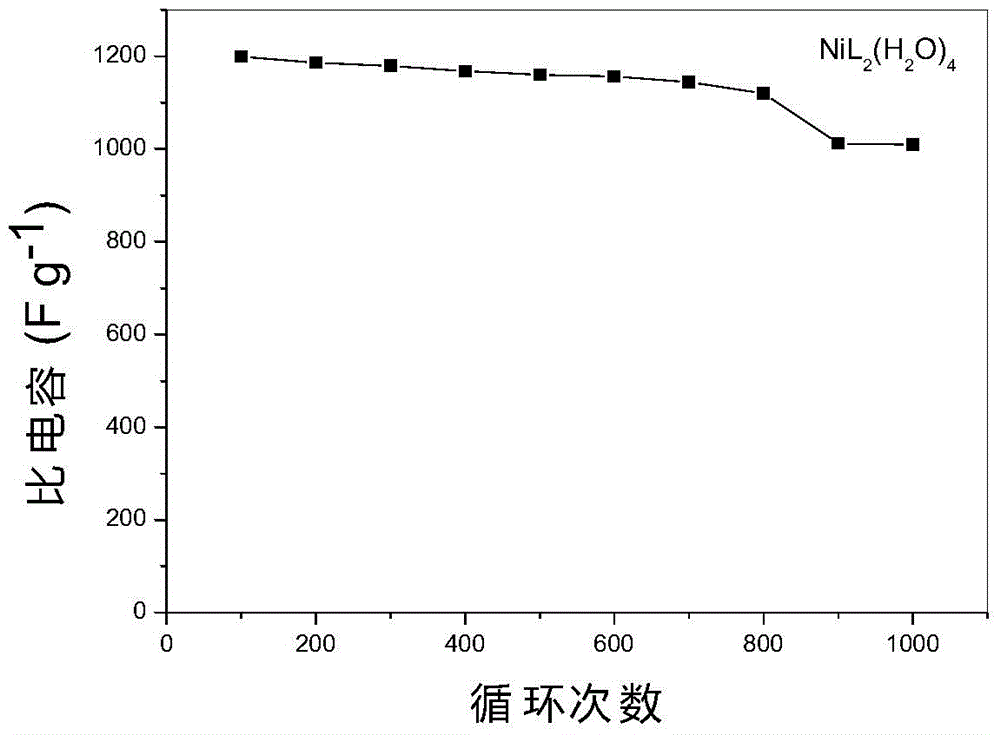

[0047] Weigh 15 grams of NiL separately 2 (H 2 O) 4 (L=4-pyridinecarboxylate), 4 grams of superconducting carbon black and 1 gram of polytetrafluoroethylene are put into a beaker, after mixing evenly, add an appropriate amount of absolute ethanol until the substance in the beaker is submerged, and then place the beaker under magnetic heating After stirring on the stirrer for 1 hour, use a spatula to coat the material in the stirred beaker on the nickel foam of the positive current collector, and the nickel foam size is 1 × 1cm 2 , thus making the positive electrode material of the supercapacitor. We use a three-electrode system for cyclic voltammetry test to test the specific capacitance of the positive electrode material, choose 3 × 5cm 2 The size of the platinum sheet and the saturated calomel electrode (SCE) were used as the auxiliary electrode and the reference electrode, and the positive electrode material made by us was used as the working electrode. The test system w...

Embodiment 2

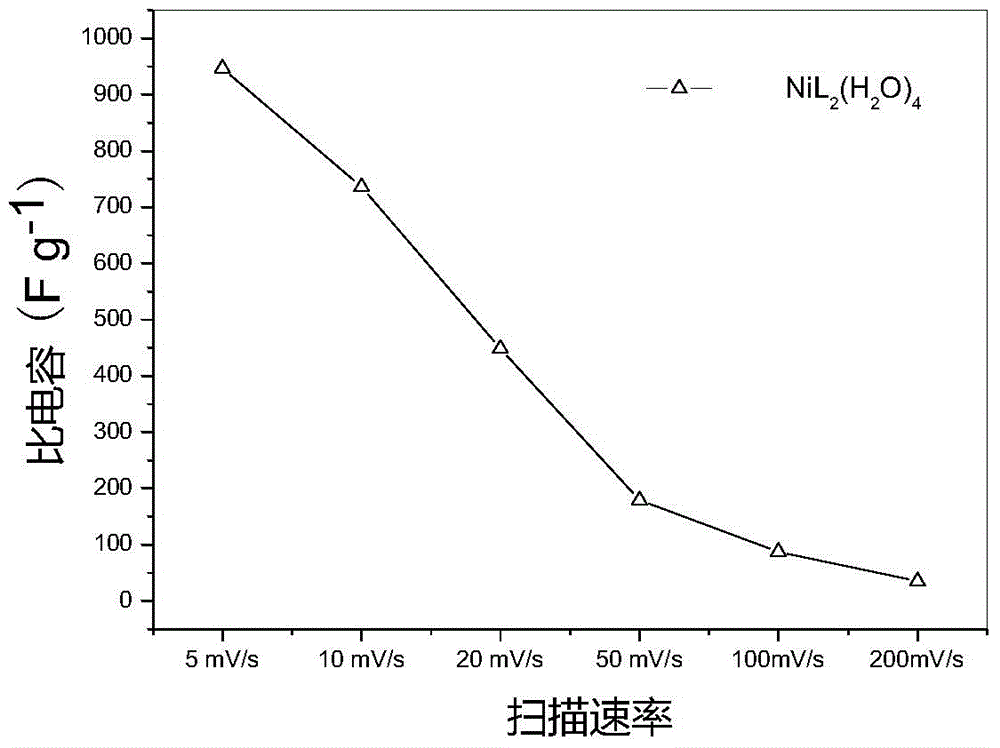

[0049] Weigh 15 grams of NiL separately 2 (H 2 O) 4 (L=4-pyridinecarboxylate), 4 grams of acetylene black and 1 gram of polyvinyl alcohol are put into a beaker, after mixing evenly, add an appropriate amount of absolute ethanol until the substance in the beaker is submerged, and then place the beaker on a magnetic heating stirrer After stirring for 1 hour, use a spatula to coat the contents of the stirred beaker on the copper foil of the positive electrode current collector, and the size of the copper foil is 1×1cm 2 , thus making the positive electrode material of the supercapacitor. We adopt three-electrode system to carry out cyclic voltammetry test, to test the specific capacitance of positive electrode material of the present invention, select 3 * 5cm for use 2 The size of the platinum sheet and the saturated calomel electrode (SCE) were used as the auxiliary electrode and the reference electrode, and the positive electrode material made by us was used as the working e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com