Calcium phosphate whisker frame and porous composite scaffold and their preparation methods

A composite scaffold and calcium phosphate technology, which is applied in the field of biomedical materials, can solve the problem of low reinforcement ratio of calcium phosphate porous composite materials, achieve high strength, increase strength, and increase fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

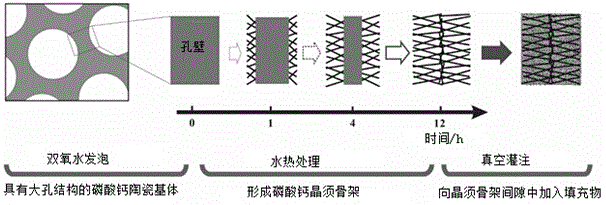

[0037] Preparation of High Strength Macroporous Calcium Phosphate Bioactive Ceramic Scaffolds Composite with Biphasic Calcium Phosphate Particles with Hydroxyapatite Whisker Framework:

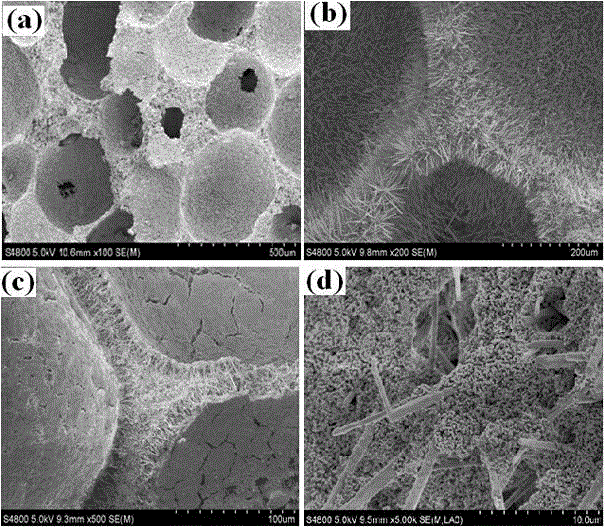

[0038]⑴ Customized macroporous biphasic calcium phosphate (BCP, HA / β-TCP=2:8) ceramic scaffold. The porosity of the macroporous biphasic calcium phosphate ceramic scaffold is 70%±2%, the diameter of the macropores is 200-500 μm, and the diameter of the through-holes between the macropores is 50-100 μm: the biphasic calcium phosphate (BCP) powder prepared by wet reaction is dried , followed by the hydrogen peroxide foaming method to prepare the porous ceramic green body. After the ceramic green body was sintered at 1100 °C for 2 hours, it was cut into a cylindrical block with a size of Φ5×10 mm to obtain a BCP macroporous scaffold. The microstructure of the cross section is as follows: figure 2 (a) shown.

[0039] (2) Immerse the BCP macroporous scaffold prepared in (1) in an acid solution wi...

Embodiment 2

[0046] The procedure is the same as in Example 1, except that the porosity of the porous BCP ceramic scaffold used in this example is 76%±3%. The results show that the composite scaffold still has a multi-level interconnected pore structure and the porosity is still about 76% when the filler fills the whisker gap of the mesopore wall. The test results of the mechanical test are shown in Table 2: Compared with the untreated BCP (A2), the whisker skeleton itself (B2) has an increase of about 82% in compressive strength and about 1 times the compression modulus; HA whisker Compared with the same batch of unreinforced calcium phosphate porous scaffolds (A2), the skeleton-based calcium phosphate ceramic composite scaffold (C2) has about 3.1 times higher compressive strength and about 3.9 times higher compressive modulus. The effect is also very significant.

[0047] The mechanical test result of each sample in table 2 embodiment 2

[0048] Sample serial number A2 B2 ...

Embodiment 3

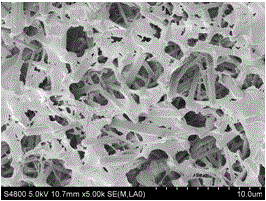

[0050] The calcium phosphate whisker framework was filled with collagen to prepare a macroporous calcium phosphate whisker framework-collagen composite scaffold. The porosity of the porous BCP ceramic support used in this example is 76% ± 3%. The preparation method of the calcium phosphate whisker skeleton is the same as in Example 2, except that the collagen solution of 5 mg / ml is used instead of Example 1. The BCP nanoslurry vacuum-filled HA whisker-skeletal scaffolds. Immerse the collagen-infused whisker skeleton in 0.5% glutaraldehyde aqueous solution to cross-link the collagen to obtain a macroporous calcium phosphate whisker skeleton-collagen composite scaffold, whose microstructure is as follows: image 3 As shown, the filler filled the whisker gap of the mesopore wall, and the obtained composite scaffold still had a multi-level interconnected pore structure, and the porosity was still about 76%. The mechanical test results show that: compared with the same batch of un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com