Fluorosurfactants free of PFOA and its salts

A surfactant and perfluorooctanoic acid technology, applied in the field of fluoropolymers and fluorosurfactants, can solve the problems of being amplified, chemical characteristics that cannot be characterized by any molecular chain or group in its structural formula, and vast differences. , to achieve the effect of reducing surface tension, good surface activity characteristics, and good surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

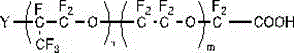

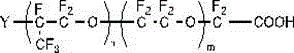

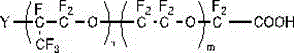

Image

Examples

Embodiment 1

[0045] This example proposes a fluorine-containing surfactant that does not contain perfluorooctanoic acid and its salts. After the fluorine-containing surfactant is continuously fed with perfluoroolefin, oxygen and a third monomer at a temperature of 0°C and a pressure of 0.1Mpa , prepared by photooxidation, hydrolysis, and salt formation. The third monomer is an alkene or alkyne containing at least one non-fluorine atom, such as chloroacetylene. The fluorine-containing surfactant satisfies:

[0046] Acid value: 148mg / g;

[0047] Peroxygen value: 0.001%;

[0048] Boiling point: 130°C;

[0049] Surface tension: 10mN / m;

[0050] Critical micelle concentration: 0.8%;

[0051] Perfluorooctanoic acid and its salts: 0.

Embodiment 2

[0053] The fluorine-containing surfactant involved in this example is prepared by continuous feeding of perfluoroalkene, oxygen and the third monomer at a temperature of 20°C and a pressure of 0.5Mpa, followed by photooxidation, hydrolysis, and salt formation. The third monomer is an alkene or alkyne containing at least one non-fluorine atom, such as vinyl chloride, and the fluorine-containing surfactant satisfies:

[0054] Acid value: 120mg / g;

[0055] Peroxide value: 1%;

[0056] Boiling point: 370°C;

[0057] Surface tension: 30mN / m;

[0058] Critical micelle concentration: 5%;

[0059] Perfluorooctanoic acid and its salts: 0.

Embodiment 3

[0061] The difference between this example and Example 1 is that the peroxygen value of the fluorine-containing surfactant in this example satisfies 0.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com