Supersaturated brazing filler metal and preparation method thereof

A technology of solder and silver-based solder, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems affecting the popularization and application of silver-based solder, the difficulty of processing the solder, and the difficulty in meeting the needs of beneficial elements in microstructure and properties. problems, to achieve the effect of saving content, short implementation time, and reducing raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

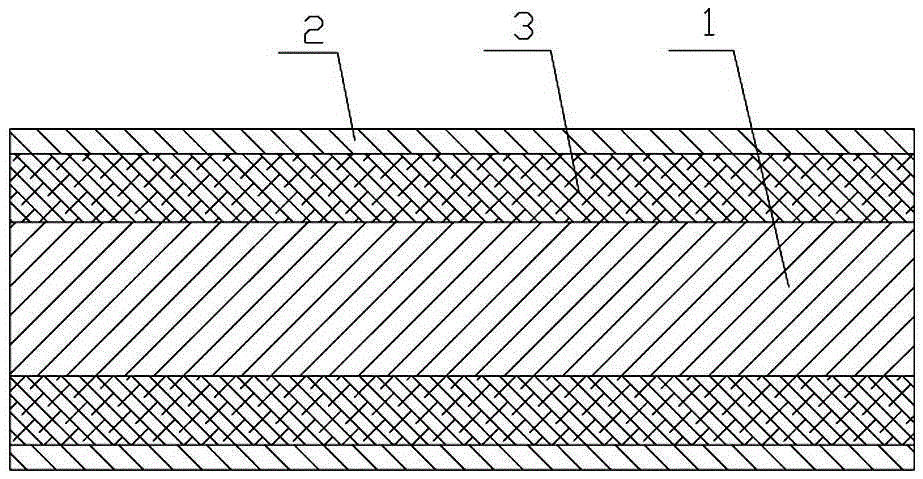

Image

Examples

preparation example Construction

[0019] The preparation method of supersaturated solder of the present invention is:

[0020] First put the metal material of the base solder into the HRJ-13 smelting furnace, and prefabricate the base solder through casting, annealing, extrusion, rolling or drawing; then use the conventional electroforming process on the surface of the base solder Electroforming metal layer (electroforming equipment model EFT6300), after the electroforming process is completed, the metal layer is infiltrated into the base solder by using the temperature gradient diffusion method of the protective atmosphere. The specific operation steps are: first put it into 25~250 °C VDF-7160 vacuum drying oven for 0.5~10min (the reaction principle is the thermal motion of atoms), and then put it into the HTL-30 heat treatment furnace at 20~230°C for 2~30h (metallurgical reaction, forming a compound phase) ), and then cooled with the furnace to obtain supersaturated solder.

Embodiment 1

[0023] A supersaturated silver-based solder is prepared, the base solder is BAg60Cu, the metal layer is an indium electroforming layer, and the transition layer is composed of an AgIn compound phase and a CuIn compound phase. The weight percentages of the base solder, the transition layer and the metal layer are as follows, the base solder is 87.5%, the transition layer is 11.9%, and the metal layer is 0.6%.

[0024] First put 600g of metal silver and 400g of copper into the melting furnace, and prefabricate it into a sheet-shaped matrix solder BAg60Cu with a thickness of 0.35mm through casting, annealing, extrusion, rolling or drawing; The front and back sides of the solder are electroformed with indium (the thickness of one side is 21 μm); after the electroforming process is completed, the indium metal layer is infiltrated into the BAg60Cu matrix solder by using the temperature gradient diffusion method of the protective atmosphere. The BAg60Cu solder of the indium electrofo...

Embodiment 2

[0027] A supersaturated silver-based solder is prepared, the base solder is BAg50Cu, the metal layer is an indium-tin alloy electroforming layer, and the transition layer is composed of AgCuSn compound phase, AgCuIn compound phase, CuIn compound phase and CuSn compound phase. The weight percentages of the base solder, the transition layer and the metal layer are as follows: 90.0% of the base solder, 9.5% of the transition layer, and 0.5% of the metal layer.

[0028] First put 500g of metallic silver and 500g of copper into the melting furnace, and form it through casting, annealing, extrusion, rolling or drawing, and prefabricate it into a sheet-shaped matrix solder BAg50Cu with a thickness of 0.30mm; then use the alloy electroforming indium tin process Electrocast indium tin on the front and back of the BAg50Cu matrix solder (thickness on one side is 16 μm); after the alloy electroforming process is completed, use the temperature gradient diffusion method of the protective atm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com