Spherical nano-porous hydroxylapatite prepared through shells and preparation method thereof

A hydroxyapatite and nanoporous technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of waste and utilization of shell resources, and achieve uniform particle size, cheap and easy-to-obtain raw materials, and mild preparation conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

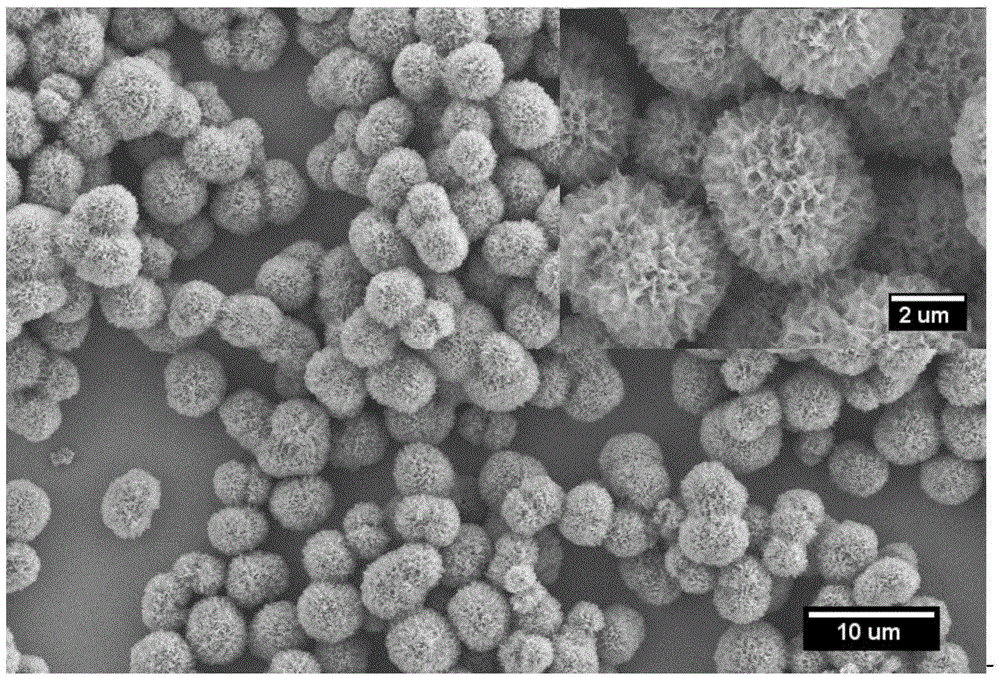

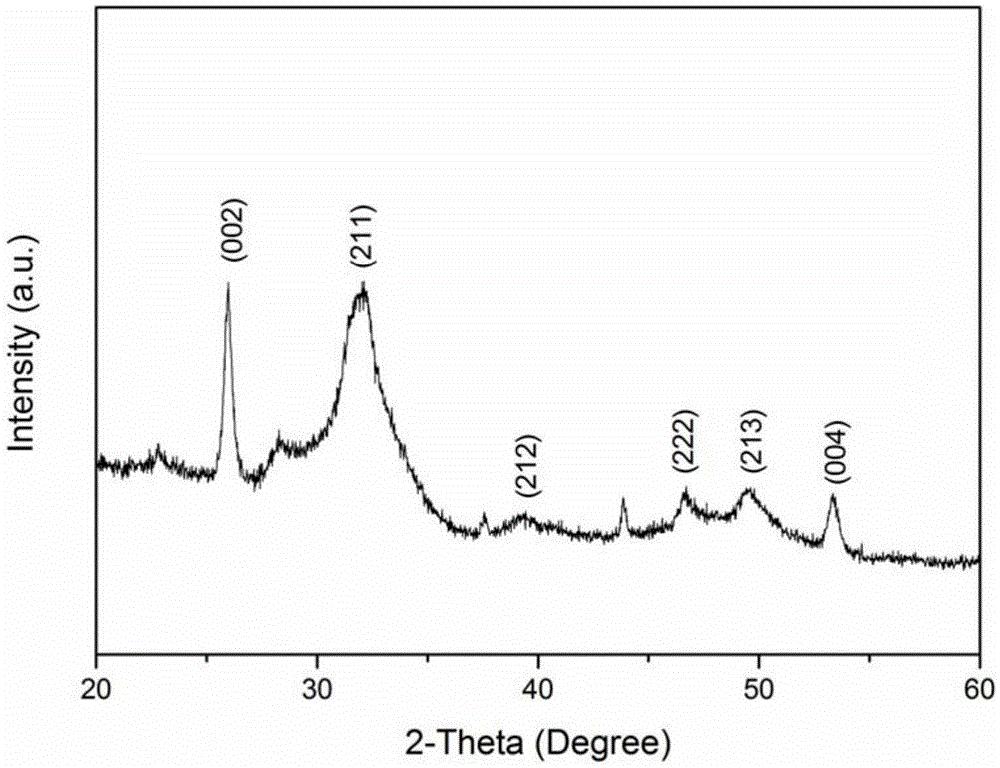

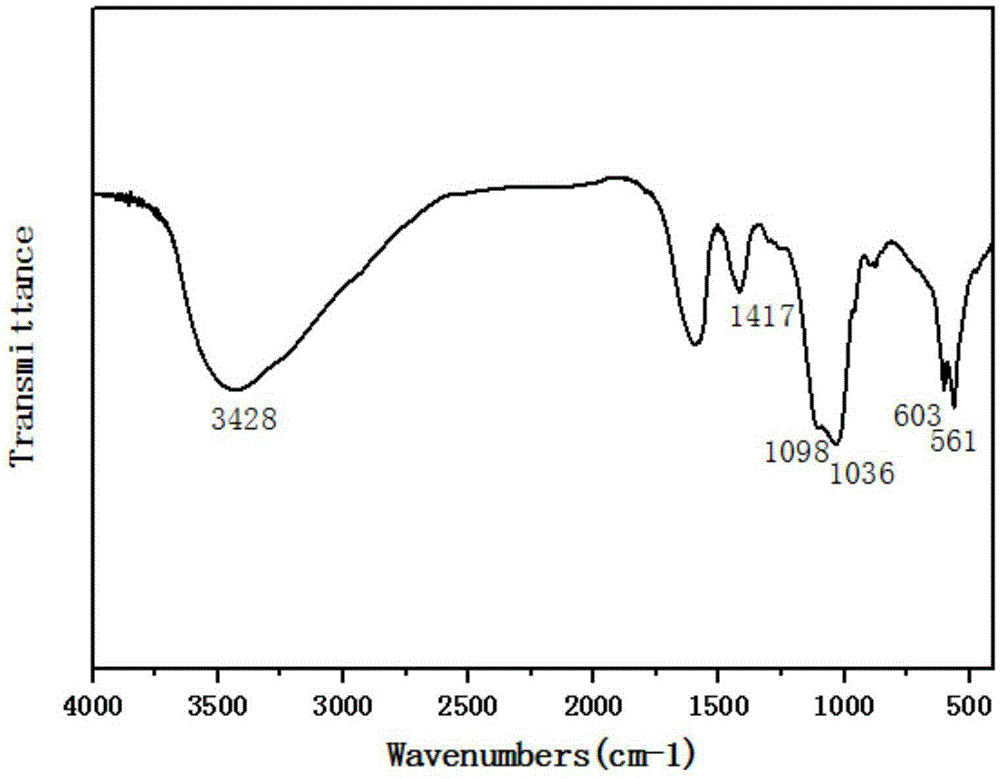

[0031] After cleaning and drying the mussel shells, grind them into a powder with a particle size of 100 mesh, take 0.5g of shell powder and add it to a beaker; add 20mL of acetic acid solution with a concentration of 0.1g / mL, react for 1h, take the supernatant after centrifugation, and use Dilute to 50mL with deionized water; take 50mL of 0.06mol / LH 3 PO 4 Solution, while stirring, add H at a rate of 10 drops / min 3 PO 4 Add the solution dropwise into the solution; then add 0.4mmol trisodium citrate to the mixed solution, stir for 30min, then add 6g of urea; put the prepared mixed solution in a water bath at 90°C, stir for 5min, and let stand until Precipitation appeared; finally, the obtained precipitate was filtered, washed twice with deionized water, washed twice with ethanol, and dried at 70° C. for 24 hours to obtain spherical hydroxyapatite particles.

[0032] The spherical nanoporous hydroxyapatite is characterized by a particle size of 4-5 μm and a specific area of ...

Embodiment 2

[0035] After cleaning and drying the mussel shells, grind them into a powder with a particle size of 100 mesh, take 0.5g of shell powder and add it to a beaker; add 20mL of acetic acid solution with a concentration of 0.1g / mL, react for 1h, take the supernatant after centrifugation, and use Dilute to 50mL with deionized water; take 50mL of 0.12mol / LH 3 PO 4 Solution, while stirring, add H at a rate of 10 drops / min 3 PO 4 Add the solution dropwise into the solution; then add 0.4mmol trisodium citrate to the mixed solution, stir for 30min, then add 6g of urea; put the prepared mixed solution in a water bath at 90°C, stir for 5min, and let stand until Precipitation appeared; finally, the obtained precipitate was filtered, washed twice with deionized water, washed twice with ethanol, and dried at 70° C. for 24 hours to obtain spherical hydroxyapatite particles.

Embodiment 3

[0037] After cleaning and drying the oyster shells, grind them into a powder with a particle size of 200 mesh, take 0.5g shell powder and add it to a beaker; add 20ml of acetic acid solution with a concentration of 0.1g / mL, react for 1h, and take the supernatant after centrifugation, and use Dilute to 50mL with deionized water; take 50mL of 0.06mol / LH 3 PO 4 Solution, while stirring, add H at a rate of 20 drops / min 3 PO 4 Add the solution dropwise into the solution; then add 0.6mmol trisodium citrate to the mixed solution, stir for 30min, then add 6g of urea; put the prepared mixed solution in a water bath at 80°C, stir for 5min, and let stand until Precipitation appeared; finally, the obtained precipitate was filtered, washed twice with deionized water, washed twice with ethanol, and dried at 70° C. for 24 hours to obtain spherical hydroxyapatite particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com