Controllable nanocrystalline TiO2 particle, and preparation method and use thereof

A crystalline and particle technology, applied in nanotechnology, nanotechnology, sustainable manufacturing/processing, etc., can solve the problems of small scale, low production efficiency, and inability to prepare nanocrystalline TiO2 particles as desired

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] A controllable nanocrystalline TiO 2 The preparation method of particles includes the following steps:

[0048] a. Add tetraisopropyl titanate to the acidic solution, and then stir and react to obtain a titanium sol;

[0049] b. Hydrothermal reaction of titanium sol;

[0050] c. After the hydrothermal reaction is over, remove the liquid phase, wash to neutral, and dry to obtain nanocrystalline TiO 2 Particles.

[0051] The above-mentioned controllable nanocrystalline TiO 2 In step a of the particle preparation method, in order to reduce the speed of the hydrolysis reaction, thereby controlling the consistency of the product particle size distribution, particle size and other factors, the stirring reaction temperature is preferably 0-4°C.

[0052] The above-mentioned controllable nanocrystalline TiO 2 In step a of the particle preparation method, in order to reduce the hydrolysis rate of tetraisopropyl titanate, the tetraisopropyl titanate is diluted with alcohol and then added to...

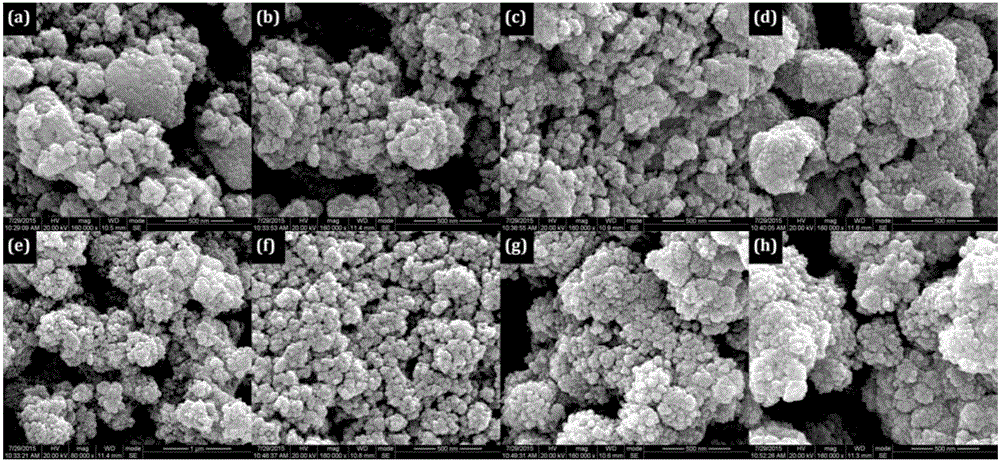

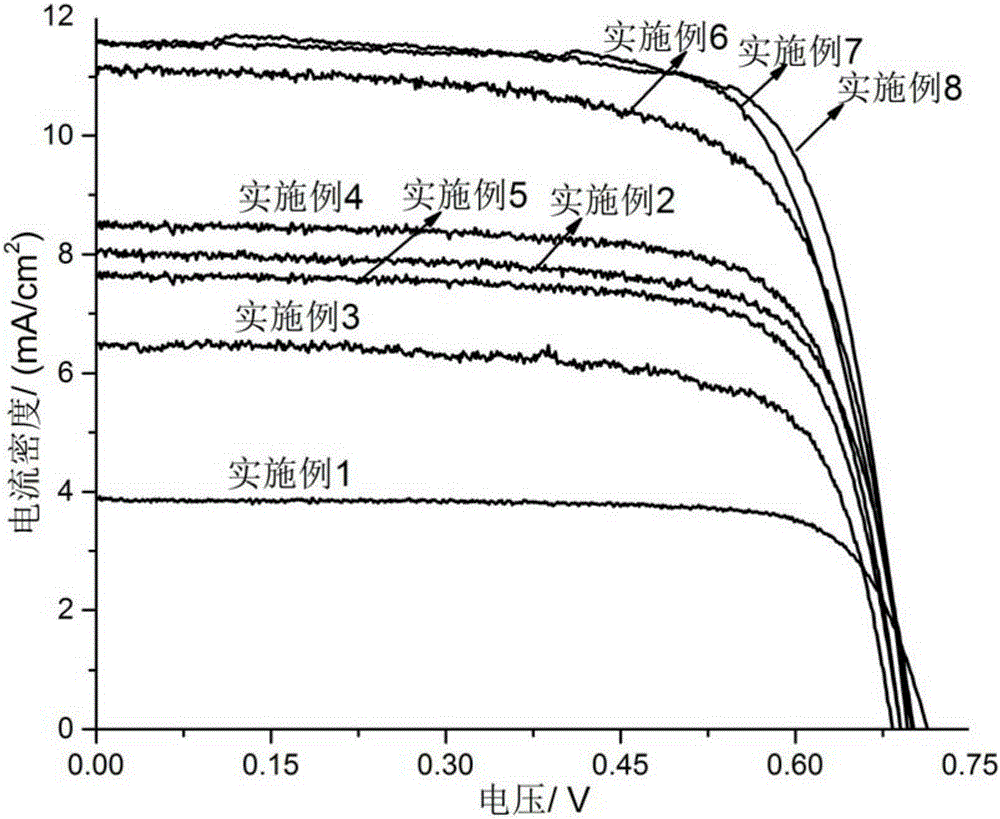

Embodiment 1

[0072] Nanocrystalline TiO 2 Preparation of particles: Weigh 2.27g of tetraisopropyl titanate as solvent A, add 2mL of concentrated nitric acid into 76mL of deionized water and mix uniformly to form solution B, place solution B in an ice water bath, and dilute the solvent A to 0.5 mL / min was added dropwise to solution B and stirred vigorously for 2 hours to form a sol. The sol was transferred to a hydrothermal kettle lined with para-polyphenol and heated to 140°C at a temperature increase rate of 1°C / min, and then taken out after 6 hours. The hydrothermal kettle was naturally cooled to room temperature, the supernatant in the lining was skimmed, washed with deionized water under ultrasonic conditions, and centrifuged to remove organic matter and excess acid. Repeated washing to pH 7.0, using absolute ethanol Exchange most of the water, transfer to a rotary evaporator to quickly remove most of the water and ethanol, and finally place it in a vacuum drying oven at 90°C for 2 hours...

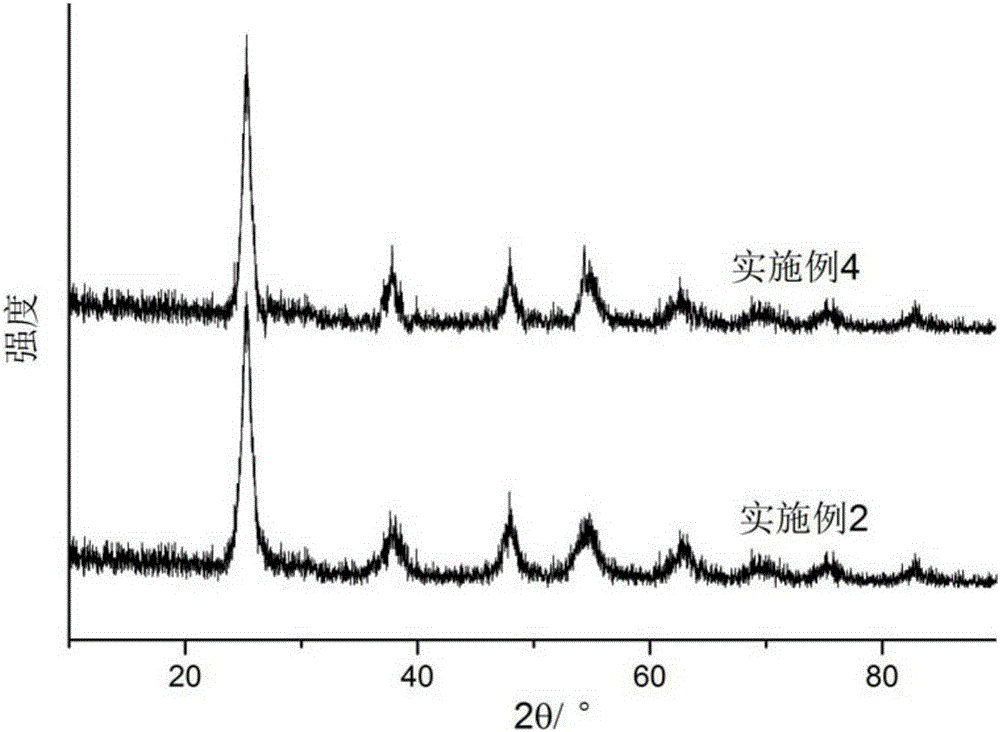

Embodiment 2

[0080] Nanocrystalline TiO 2 Preparation of particles: Weigh 2.27 g of tetraisopropyl titanate as solvent A, add 10 mL of concentrated nitric acid into 68 mL of deionized water and mix uniformly to form solution B, place solution B in an ice water bath, and dilute the solvent A to 0.5 mL / min was added dropwise to solution B and stirred vigorously for 2 hours to form a sol. The sol was transferred to a hydrothermal kettle lined with para-polyphenol and heated to 140°C at a temperature increase rate of 1°C / min, and then taken out after 6 hours. The hydrothermal kettle was naturally cooled to room temperature, the supernatant in the lining was skimmed, washed with deionized water under ultrasonic conditions and centrifuged to remove organic matter and excess acid. Repeated washing to pH 7.0, using absolute ethanol Exchange most of the water, transfer to a rotary evaporator to quickly remove most of the water and ethanol, and finally place it in a vacuum drying oven at 90°C for 2 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com