A method for making light ceramsite by utilizing chromium-containing sludge

A light-weight ceramsite and chromium sludge technology, applied in the field of light-weight ceramsite, can solve the problems of high cost or potential cost, difficulty in secondary pollution, low addition ratio of chrome sludge, etc., and achieves low production cost and detoxification. Thorough, muddy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

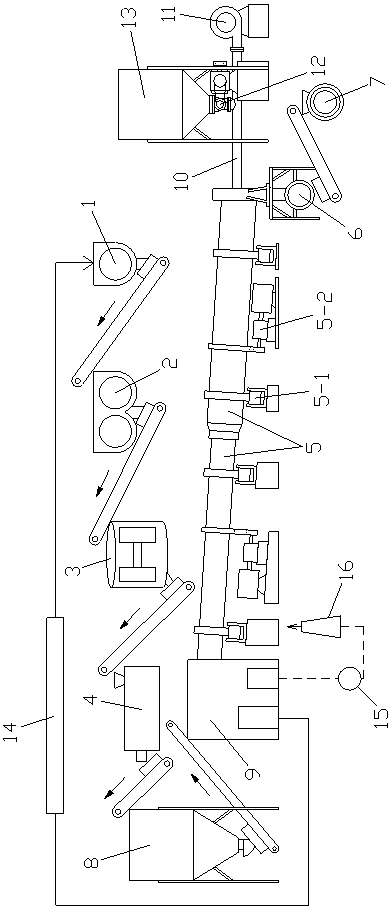

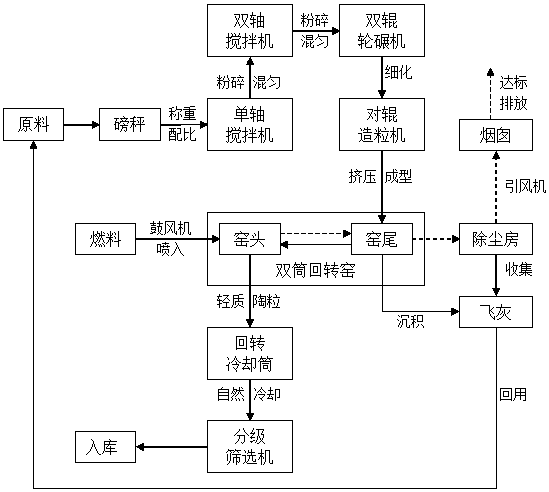

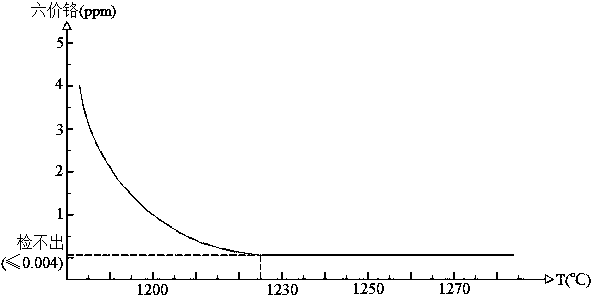

[0041] Example 1: Wet grind chromium-containing sludge to 150 mesh (the weight is 30wt% of the mixed sludge before firing), add and dry to 5% moisture content and dry grind to 100 mesh urban sludge, weathered rock, silt , clay or kaolin (the weight is 55wt% of the mixed mud before firing), and then dry-milled to 100 mesh reducing agent (the weight is 10wt% of the mixed mud before firing) and bulking agent (the weight is 10wt% of the mixed mud before firing) 5wt%), mixed uniformly, etc., the mixed sample was pressed by a granulator to grow into a long strip-shaped ceramsite raw meal of 20mm×10mm×10mm, and dried in the low-temperature zone of 300°C at the kiln tail of the double-cylinder rotary kiln 5 40 minutes, and then calcined in the high temperature zone of 1200°C at the kiln head for 50 minutes, discharged and cooled to obtain light-weight ceramsite finished products.

Embodiment 2

[0042] Example 2: Wet grind chromium-containing sludge to 160 mesh (the weight is 35wt% of the mixed mud before firing), add and dry to 6% moisture content and dry grind to 120 mesh urban sludge, weathered rock, and silt Or kaolin (the weight is 55wt% of the mixed mud before firing), and then dry-milled to 120 mesh reducing agent (the weight is 9wt% of the mixed mud before firing) and expanding agent (the weight is 1wt% of the mixed mud before firing ), mixed uniformly and other treatments, the mixed sample was pressed by a granulator to grow into a cylindrical ceramic raw material with a diameter of 20mm and a diameter of 10mm, and was dried in the low temperature zone of 350°C at the kiln tail of the double-cylinder rotary kiln 5 for 40 minutes, and then in the The kiln head is calcined in the high temperature zone of 1250°C for 45 minutes, and the light ceramsite product is obtained after discharging and cooling.

Embodiment 3

[0043] Example 3: Wet grind chromium-containing sludge to 170 mesh (the weight is 40wt% of the mixed mud before firing), add and dry to 7% moisture content and dry grind to 130 mesh urban sludge, weathered rock, and silt Or kaolin (the weight is 50wt% of the mixed mud before firing), and then add dry grinding to 130 mesh reducing agent (the weight is 8wt% of the mixed mud before firing) and expanding agent (the weight is 2wt% of the mixed mud before firing ), mixed uniformly and other treatments, the mixed sample was pressed into a spherical ceramic raw material with a diameter of 10mm by a granulator, dried in the low temperature zone of the kiln tail of the double-cylinder rotary kiln 5 at 400°C for 35 minutes, and then dried at the kiln head at 1250°C Calcined in the high temperature zone for 40 minutes, discharged and cooled to obtain light ceramsite finished products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com