Barreled water tray and processing method thereof

A processing method and technology for bottled water, applied in the directions of packaging, transportation and packaging, containers, etc., can solve the problems of easy rupture, inconvenient transportation of bottled water, etc., to reduce production costs, solve inconvenient transportation, and reasonable structural design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

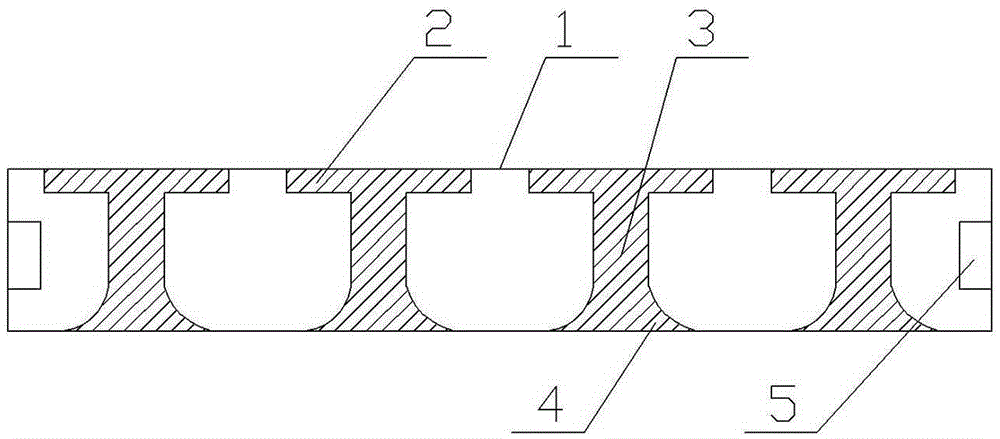

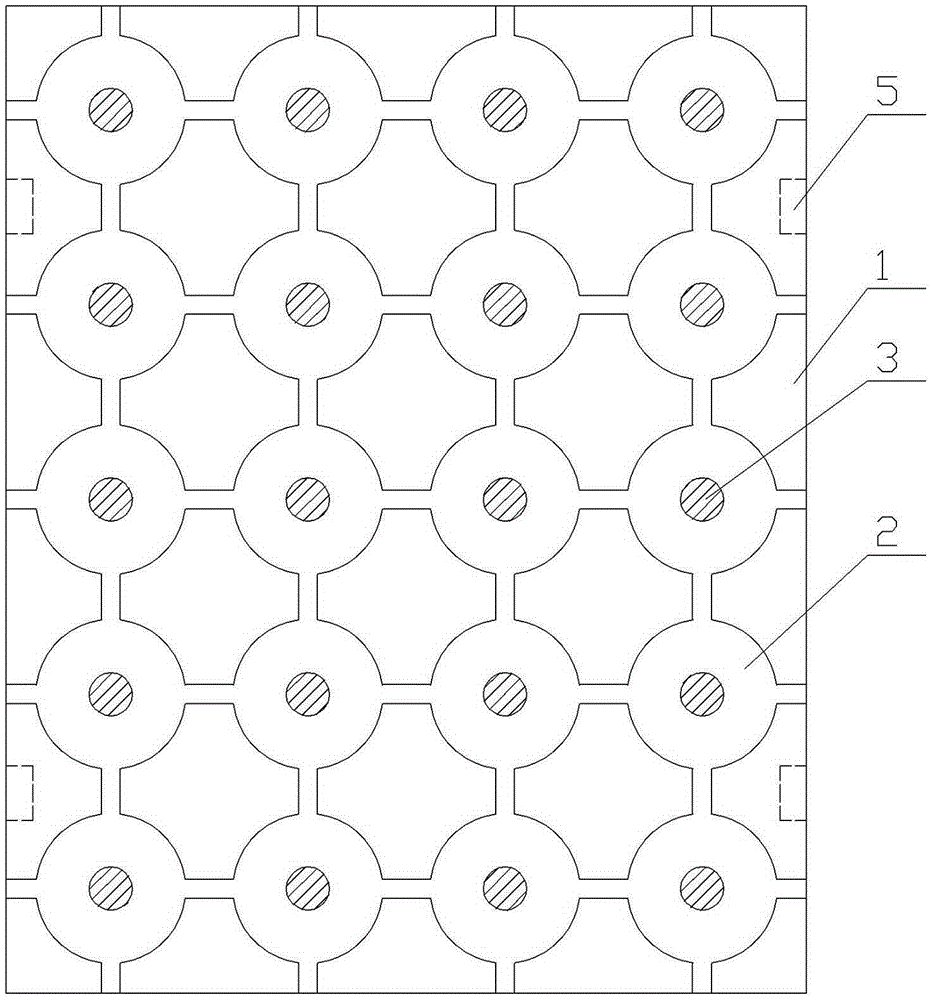

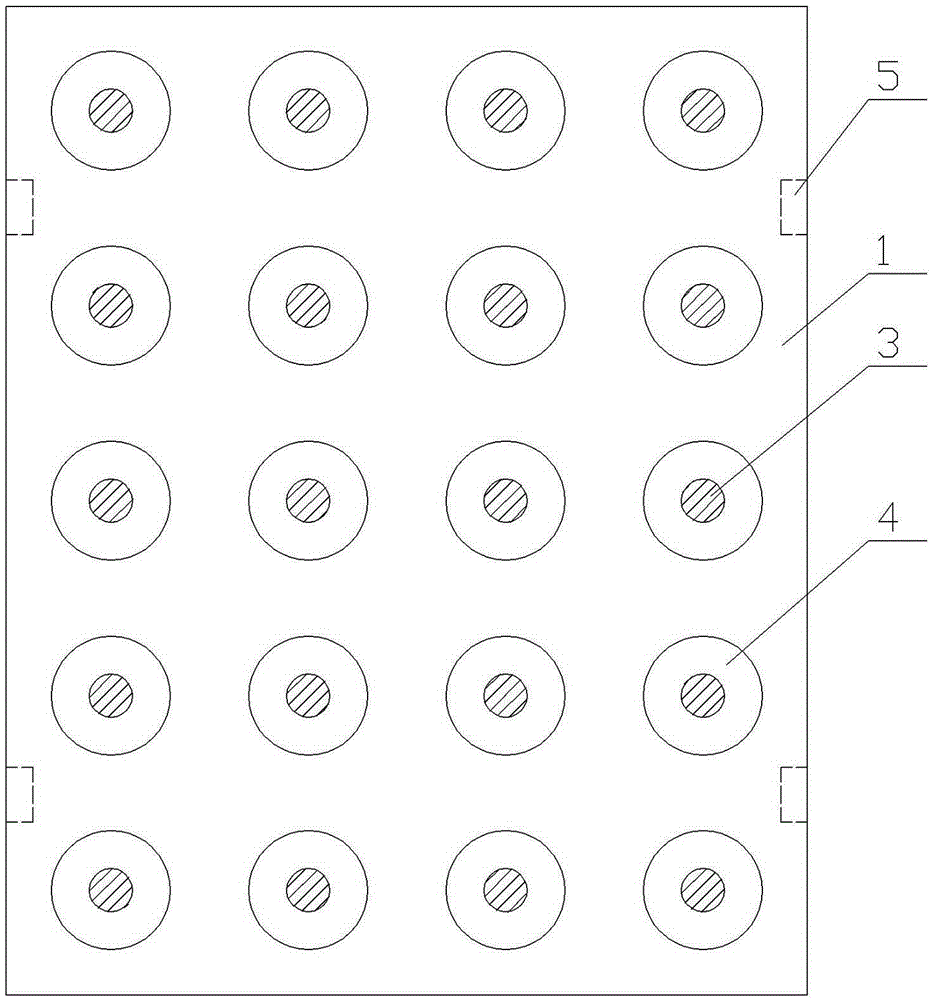

[0022] refer to figure 1 , figure 2 and image 3 , a barreled water tray, which includes a tray 1, two concave handles 5 are provided on both sides of the tray; circular bucket seat grooves 2 distributed in a rectangular array are provided on the tray The back of the tray corresponding to the barrel seat groove is provided with a barrel neck groove 4; the barrel seat groove and the barrel neck groove are connected through the communication hole 3.

[0023] The barrel neck groove and the communication hole are connected in an arc surface.

[0024] Before loading bottled mineral water, first lay a tray in the compartment with the groove of the bucket seat facing upwards, then place the bucket neatly in the groove of the bucket seat, after the bucket is full, continue to lay the tray on the bucket, the neck of the tray is concave The groove is sleeved on the barrel neck of the water bucket, and the water outlet of the water bucket is just located in the communication hole. A...

Embodiment 2

[0026] A barreled water tray, which is prepared from the following raw materials in parts by weight:

[0027] 0.1 part of sepiolite powder, 0.1 part of zinc stearate, 0.2 part of white graphite, 0.5 part of talc powder, 0.6 part of pentaerythritol, 1 part of cyclopentasiloxane, 1.5 part of phthalate, trimer 1.5 parts of sodium phosphate, 3 parts of calcium silicate, 5 parts of dolomite powder, 6 parts of chitin, 10 parts of borax, 22 parts of epoxy acrylate resin, 25 parts of phenolic resin, 45 parts of polyethylene resin. Among them, the particle diameters of sepiolite powder, white graphite, talc powder, dolomite powder and borax are all 200 mesh.

[0028] The processing method of the barreled water tray comprises the following steps:

[0029] Take each raw material according to parts by weight for subsequent use;

[0030] Sepiolite powder, white graphite, cyclopentasiloxane, phthalate, sodium tripolyphosphate, calcium silicate, dolomite powder, borax, epoxy acrylate resin...

Embodiment 3

[0034] Example 2 of the present invention takes the production of a tray with a length, width and height of 500mm×500mm×80mm as an example, and its performance test is shown in Table 1:

[0035] Table 1

[0036] group Example 2 Bending strength Mpa ≥100 Static load (tons) 5.1 Dynamic load (ton) 2.3 Diagonal drop from 5M height No damage 6 hours under steam at 100°C no softening 30 days at -30°C No embrittlement

[0037] Heat resistance: The test group was placed in hot water at 100°C for 24 hours. After taking it out, there was no obvious change on the surface, and the bending strength and load remained above 99%.

[0038] Corrosion resistance: The test group was placed in 10% salt water for 200 hours of corrosion, the surface remained bright without significant changes, and the bending strength and load remained above 98%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com