Flexible cadmium telluride solar cells with graphene intercalation layer

A technology of solar cells and insertion layers, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of device performance degradation stability, unsatisfactory effect, and thickness affecting battery electrical connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

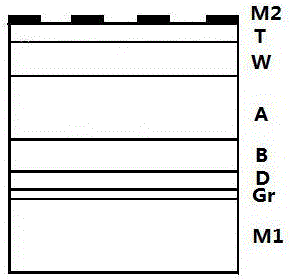

[0021] I. First, deposit graphene (Gr) by CVD method, put Ni foil (M1) into the vacuum chamber, and evacuate to about 2×10 4 Pa, the substrate temperature is 900 0 C~1000 0 C, introduce argon gas mixed with 5% methane, the gas flow rate is 50 sccm, hydrogen gas is 500 sccm, the deposition time is about 50-120 s, and 2000 sccm argon gas and 500 sccm hydrogen gas are introduced during the cooling process.

[0022] II. Next, deposit about 1 nm of Bi(D) and about 50 nm of Te(B) by evaporation.

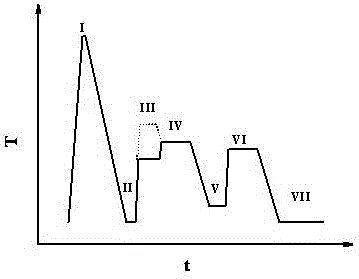

[0023] III~IV. Subsequently, as attached figure 2 As shown by the solid line in process III, cadmium telluride (A) is prepared by evaporation method with a thickness of about 5000 nm, and the substrate temperature is 350 0 C, followed by evaporation of 400 nm CdCl 2 , then annealed in air at 440 0 c.

[0024] V~VI. The deposition of cadmium sulfide (W) adopts the chemical water bath method, and the drugs used are all analytical reagents, prepared with secondary deionized water, and ...

Embodiment 2

[0027] I. Deposit graphene (Gr) by VD method, put Ni foil (M1) into the vacuum chamber, and evacuate to about 2×10 4 Pa, the substrate temperature is 900 0 C~1000 0 C, introduce argon gas mixed with 5% methane, the gas flow rate is 50 sccm, hydrogen gas is 500 sccm, the deposition time is about 50-120 s, and 2000 sccm argon gas and 500 sccm hydrogen gas are introduced during the cooling process.

[0028] II. Next, deposit about 1 nm of Sb (D) and about 50 nm of Te (B) by evaporation.

[0029] III~IV. Subsequently, as attached figure 2 As shown by the dotted line in process III, Cd(A) was prepared by near-space sublimation method with a thickness of about 6 000 nm and a deposition temperature of about 570 0 C, followed by evaporation of 400 nm CdCl 2 , then annealed in air at 440 0 c.

[0030] V~VI. Deposition of cadmium sulfide (W) The sputtering method deposits about 50 nm, in which the purity of the CdS target is 99.99%, and the background vacuum is ~10 -4 Pa, the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com