Method for simultaneously producing dimethyl sulfone and dimethyl sulfoxide

A technology of dimethyl sulfoxide and dimethyl sulfone, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problem of increasing the complexity of process operations, high cost of hydrogen peroxide, increasing operating costs, etc. problem, to achieve high selectivity, improve conversion rate, and reduce operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

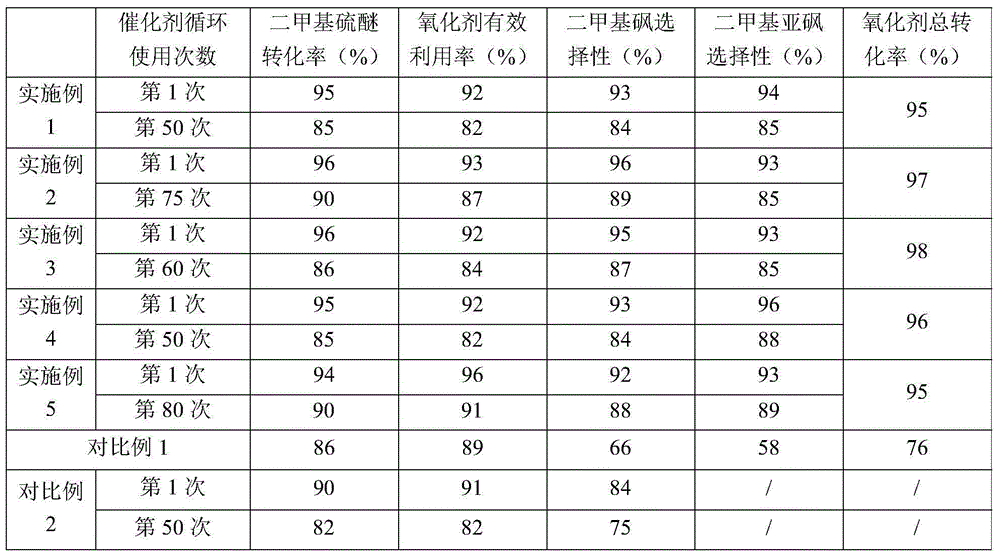

Embodiment 1

[0090] (1) The first oxidation reaction step

[0091] The original powder of titanium silicon molecular sieve TS-1 as catalyst, the first part of dimethyl sulfide, methanol as solvent and hydrogen peroxide as oxidant (provided in the form of hydrogen peroxide with a concentration of 27.5% by weight) were mixed to form a slurry and react. Wherein, the molar ratio of the first part of dimethyl sulfide to the oxidant is 1:5, the weight ratio of the first part of dimethyl sulfide to the catalyst is 10:1, and the weight ratio of the first part of dimethyl sulfide to the solvent is 1 : 5, the temperature in the reactor is 70° C., the pressure in the reactor is 0.5 MPa, and the reaction time is 2 hours.

[0092] After the reaction is completed, it is filtered to obtain the recovered catalyst and the first liquid mixture. The recovered catalyst is directly recycled, and the first liquid mixture is sent to an intermediate separation step for separation. The composition of the first ...

Embodiment 2

[0100] The reaction is carried out in the same method as in Example 1, except that in the first oxidation reaction step, the original powder of titanium-silicon molecular sieve TS-1 is modified as follows before being used as a catalyst: the original powder of titanium-silicon molecular sieve TS-1 is mixed with Hydrochloric acid (mass concentration is the aqueous solution of 36% by weight) is mixed, the mixture obtained is stirred and reacted at 90 DEG C for 5 hours, the temperature of the reaction mixture obtained is down to room temperature and then filtered, and the solid phase material obtained is dried to constant temperature at 120 DEG C. Heavy, to obtain a modified titanium silicon molecular sieve. Among them, titanium silicon molecular sieve TS-1 is made of SiO 2 Calculated, the molar ratio of titanium silicon molecular sieve to HCl is 1:0.2. After characterization, compared with the raw material titanium-silicon molecular sieve TS-1, the peak height of the absorption...

Embodiment 3

[0103] Adopt the same method as Example 1 to react, the difference is that in the first oxidation reaction step, hydrochloric acid (concentration is 36% by weight) is also added in the slurry, and the pH value of the liquid phase mixture in the slurry is adjusted by 6.3 adjusted to 5.0. The experimental results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com