Preparation method of fluor-hydroxyapatite nanoshuttle

A technology of fluorohydroxyapatite and nano-shuttle, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of high synthesis operation conditions, harsh process conditions, and large energy consumption, and achieve stable product quality, Low reaction cost and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1 Preparation of fluorohydroxyapatite nanoshuttle

[0020] In a 50mL beaker, add 2mL oleic acid, 1ml oleylamine, 10mL ethanol, then add 8mL of 0.25M calcium nitrate solution, 8mL of 0.15M sodium phosphate solution and 1.6mL of 0.25M sodium fluoride solution, stir well, seal Seal the mouth of the beaker with a porous film and let it stand at room temperature for 5 days. After the reaction, the precipitate was collected by centrifugation and washed several times with cyclohexane and ethanol to obtain the final product.

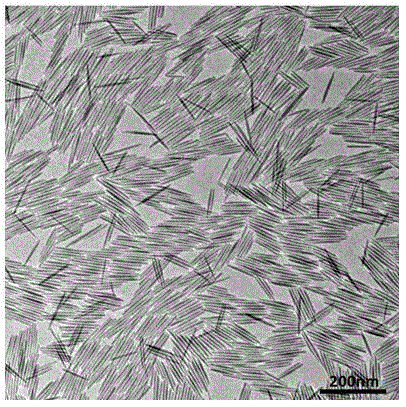

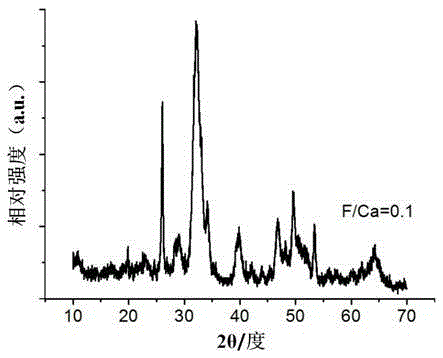

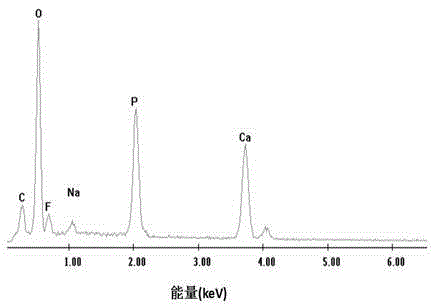

[0021] Detection by transmission electron microscopy shows that the product of the reaction is a nano-shuttle with a uniform scale, with a maximum diameter of about 10 nm and a length of about 100 nm, such as figure 1 Shown; The product identified by X-ray powder diffraction is hydroxyapatite, such as figure 2 Shown; After EDS analysis, it is known that the obtained product contains calcium, phosphorus, and fluorine elements, and is fluorine-...

Embodiment 2

[0022] Example 2 Preparation of fluorohydroxyapatite nanoshuttle

[0023] In a 50mL beaker, add 2mL oleic acid, 1ml oleylamine, 10mL ethanol, then add 0.25M calcium nitrate 8mL, 0.15M sodium phosphate solution 8mL and 0.25M sodium fluoride solution 0.8mL, stir well, seal Seal the mouth of the beaker with a porous film, and let it stand in a refrigerator at 4°C for 7 days. After the reaction, the precipitate was collected by centrifugation and washed several times with cyclohexane and ethanol to obtain the final product. The product is a nano-shuttle with uniform scale, the largest diameter is about 6nm, and the length is about 90nm.

Embodiment 3

[0024] Example 3 Preparation of fluorohydroxyapatite nanoshuttle

[0025] In a 50mL beaker, add 4mL oleic acid, 1ml oleylamine, 10mL ethanol, then add 8mL of 0.25M calcium nitrate solution, 8mL of 0.15M sodium phosphate solution and 0.8mL of 0.25M sodium fluoride solution, stir well, seal Seal the mouth of the beaker with a porous film, and let it stand in a thermostat at 10°C for 7 days. After the reaction, the precipitate was collected by centrifugation and washed several times with cyclohexane and ethanol to obtain the final product. The product is a nano-shuttle with uniform size, the largest diameter is about 8nm, and the length is about 100nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com