Filter cloth capable of forming micro-electrolysis and application of filter cloth

A micro-electrolysis and filter cloth technology, applied in the field of filter cloth, can solve the problems of inability to apply air treatment, heavy workload, loss of function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

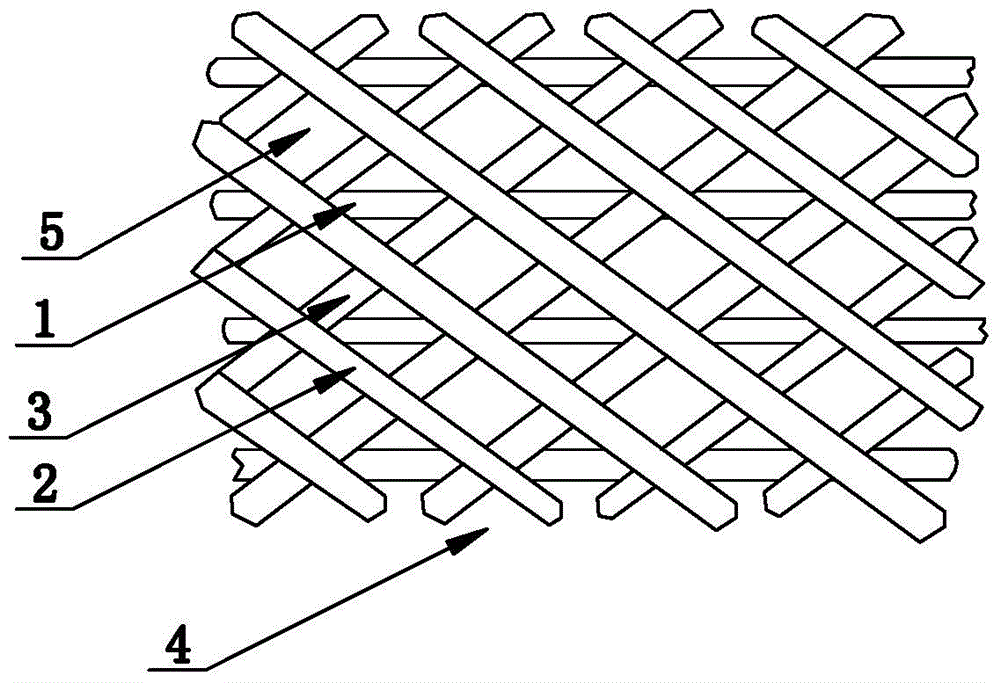

[0024] like figure 1 As shown, the filter cloth that can form micro-electrolysis is taken as 200g of carbon fiber 1, the K number of carbon fiber 1 is 1K, each of iron wire 2 and aluminum wire 3 is 100g, and the diameter of iron wire 2 and aluminum wire 3 is 0.1mm. Cloth 4, the diameter of the filter hole 5 on the base cloth 4 is 0.01mm.

[0025] Test 1: In an environment with a relative humidity of 10% and a temperature of 30°C, 8,000 volts of DC high voltage is used to energize the filter cloth in this embodiment, and keep the filter cloth moist;

[0026] With a wind speed of 1 meter per second, the polluted air containing 6,000 mg of PM2.5 particles per cubic meter is continuously passed through the above energized filter cloth, and the content of PM2.5 particles in the polluted air is reduced to 380 mg per cubic meter after being filtered by the above filter cloth. Cubic meters, the effect is remarkable;

[0027] Test 2: After the filter cloth is folded densely, the acid...

Embodiment 2

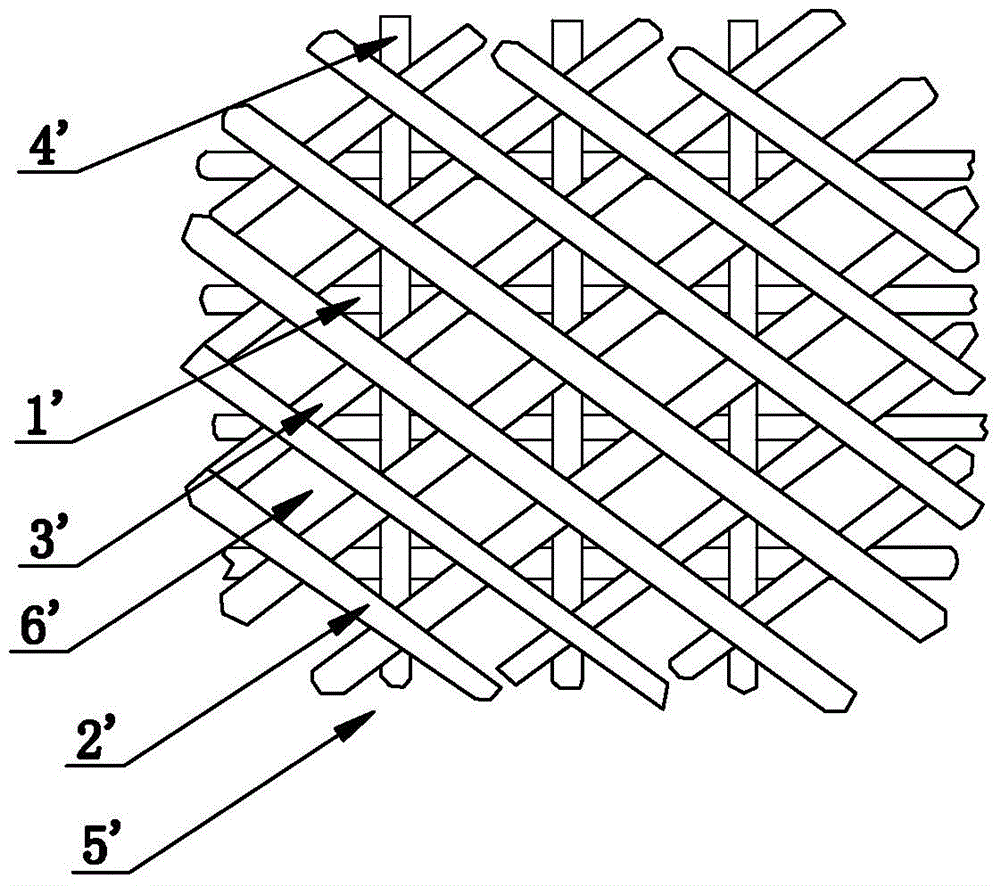

[0038] like figure 2 As shown, the filter cloth that can form micro-electrolysis, take carbon fiber 1' as 300g, the K number of carbon fiber 1' as 12K, iron wire 2', aluminum wire 3', copper wire 4' each 500g, iron wire 2', aluminum wire 3', the copper wire 4' has a diameter of 1.3 mm, and is woven into a base cloth 5', and the diameter of the filter hole 6' on the base cloth 5' is 2.5 mm.

[0039] Test 1: In an environment with a relative humidity of 30% and a temperature of 300°C, a 6,000-volt DC high voltage was used to energize the filter cloth in this embodiment and keep the filter cloth moist;

[0040] With a wind speed of 0.6 meters per second, the polluted air containing 6000 mg of PM2.5 particles per cubic meter is continuously passed through the above energized filter cloth, and the content of PM2.5 particles in the polluted air is reduced to 280 mg per cubic meter after being filtered by the above filter cloth Cubic meters, the effect is remarkable;

[0041] Test 2...

Embodiment 3

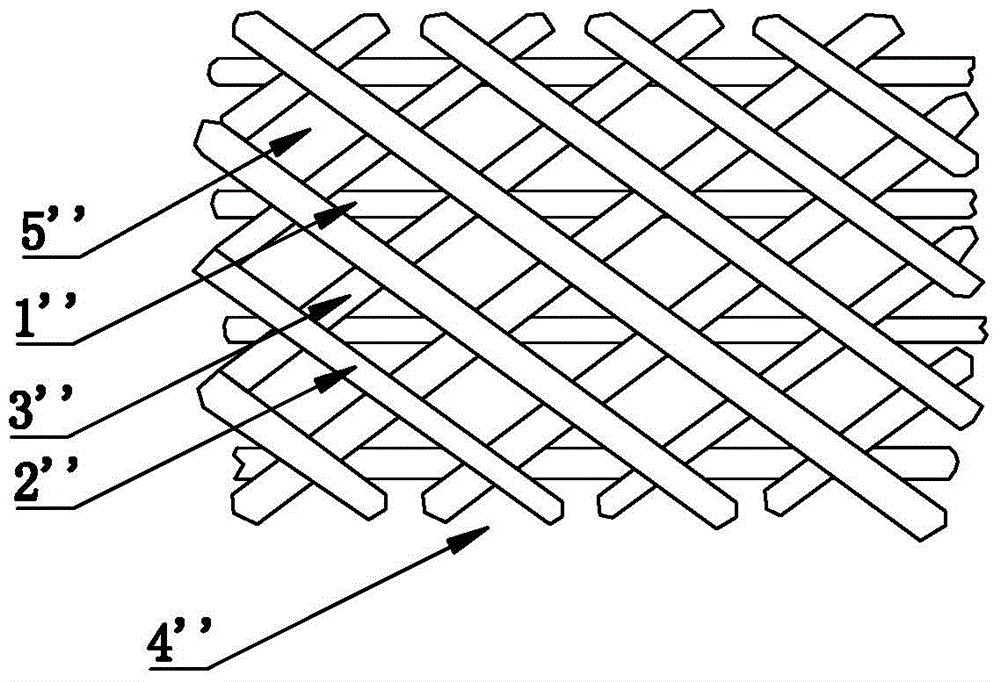

[0052] like image 3 As shown, the filter cloth that can form micro-electrolysis, take 200g of carbon fiber 1'', the K number of carbon fiber 1'' is 6K, iron wire 2'', aluminum wire 3'' each 1000g, iron wire 2'', aluminum wire 3' ' is 2.5 mm in diameter, knitted into a base cloth 4'', and the diameter of the filter hole 5'' on the base cloth 4'' is 5 mm.

[0053] Test 1: In an environment with a relative humidity of 60% and a temperature of 500°C, 10,000 volts of DC high voltage was used to energize the filter cloth in this embodiment and keep the filter cloth moist;

[0054] With a wind speed of 1.5 meters per second, the polluted air containing 6000 mg of PM2.5 particles per cubic meter is continuously passed through the above energized filter cloth, and the content of PM2.5 particles in the polluted air is reduced to 340 mg per cubic meter after being filtered by the above filter cloth Cubic meters, the effect is remarkable;

[0055] Test 2: After the filter cloth is fold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com