Dispersant-containing carbon material film containing light-responsive dispersant, and method for producing carbon material film using said dispersant-containing carbon material film

A technology of photoresponsiveness and manufacturing method, applied in the direction of photosensitive materials used in optomechanical equipment, photosensitive material processing, carbon preparation/purification, etc., can solve the problem of no report on carbon material film patterning technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0147]

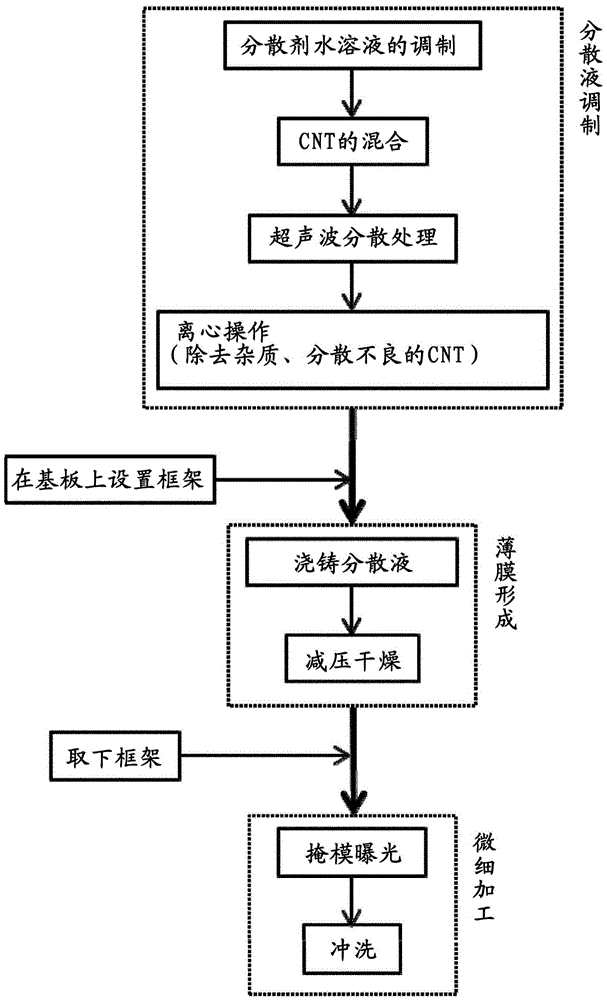

[0148] · Preparation of CNT dispersion

[0149] The weighing is represented by the following general formula (II) and R in the formula 3 and R 4 A dispersant aqueous solution was prepared by dissolving 3 mg of a butyl stilbene-based compound in 3 ml of ultrapure water (water purified by Purelab / ELGA). 1 mg of SWCNTs (produced by the HiPco method / NanoIntegris) were weighed and mixed with the above-mentioned dispersant aqueous solution. The mixed aqueous solution was treated with bath-type ultrasonic waves (37 kHz, 80 W, 1 hr) to promote the dispersion of CNTs. The obtained black liquid was centrifuged (25000×g, 4hrs, 5417R / eppendorf) to precipitate impurities such as catalyst metal and amorphous carbon, and 80% of the supernatant was recovered to prepare a CNT dispersion from which the above impurities were removed.

[0150] [hua 2]

[0151]

[0152] Preparation of CNT film containing dispersant

[0153] A fused silica substrate of 3 cm in width x 3 cm in...

Embodiment 2

[0162]

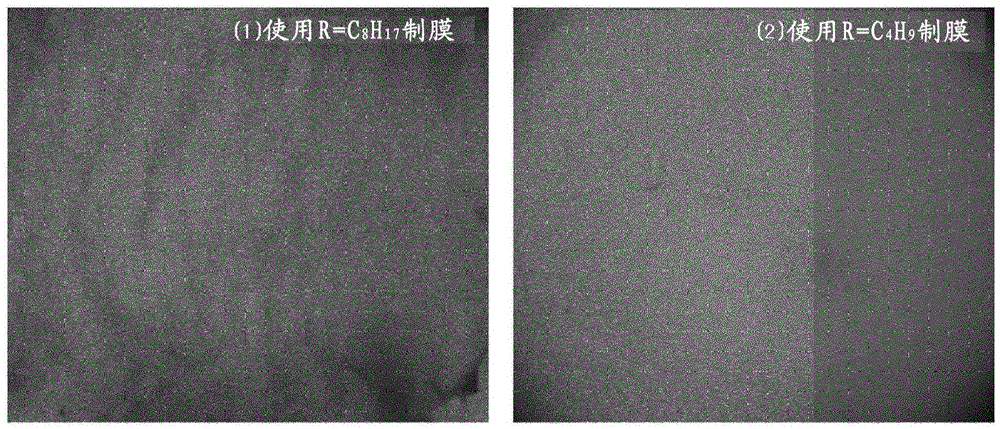

[0163] In the method shown in Example 1, the above-mentioned compound was used as a photo-responsive CNT dispersant, HiPco was used as SWCNT, and a CNT film containing a dispersant was prepared on a PET (toray Lumirror U35, easily accessible untreated surface) substrate. (the weight ratio of CNT to dispersant in the CNT film containing the dispersant is about 1:3, and the content of the liquid solvent is less than 0.1 wt%) and microfabrication via mask exposure (the dispersant content in the patterned CNT film is less than 0.1 wt%). Even if it is a substrate lacking in hydrophilicity such as PET (substrate with poor wetting of the CNT dispersion), the frame can be formed from the Si rubber sheet, so that the cast film can be easily produced. The result of optical microscope observation of the obtained microfabricated film is shown in Figure 8 middle. It was found that the line width of 10 μm or less, which is difficult in screen printing, can be processed.

[01...

Embodiment 3

[0166]

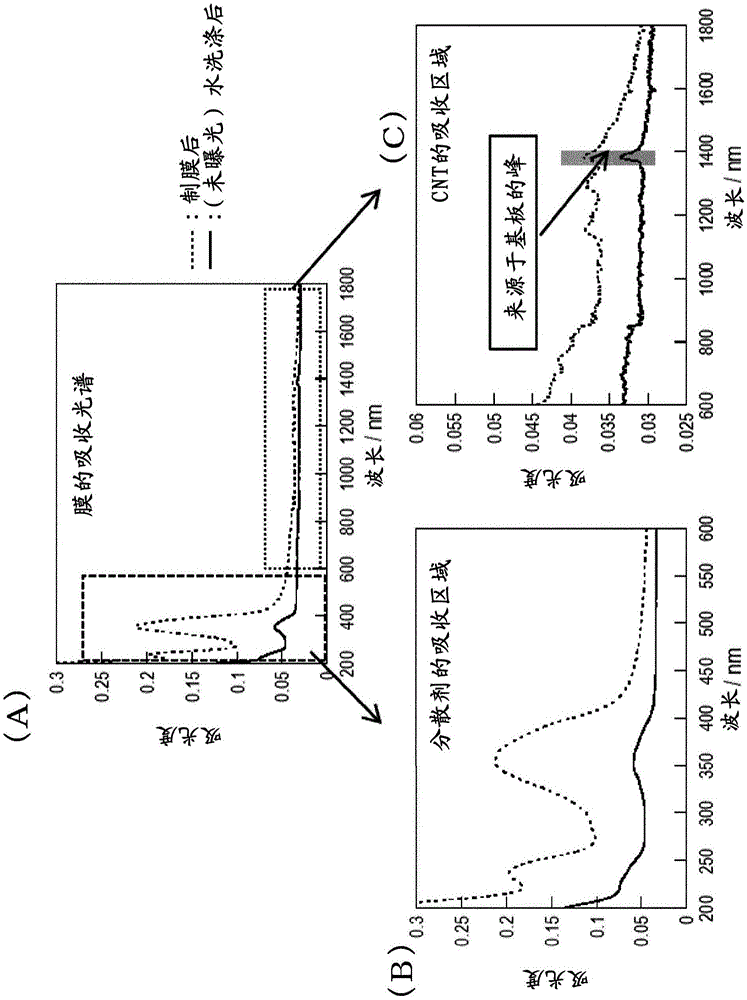

[0167] In the method shown in Example 1, instead of the stilbene-based compound of the general formula (II), an azobenzene-based compound represented by the following general formula (III) (in the formula, R 3 and R 4 As the photoresponsive CNT dispersant, HiPco was used as the SWCNT, and a dispersant-containing CNT film was fabricated on a fused silica substrate (the weight ratio of CNT to dispersant in the dispersant-containing CNT film was about 1:3, the content of the liquid solvent is less than 0.1 wt%) and the microfabrication via mask exposure (the dispersant content in the patterned CNT film is less than 0.1 wt%). The compound represented by general formula (III) is such as Figure 9 As shown in the spectrum of , E-Z isomerization proceeds by irradiating light at 385 nm, and rapidly returns to the E form in the dark. The effect of light irradiation was investigated with respect to the obtained CNT film. UV-visible-near-infrared absorption spectra (385nm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com