A kind of tissue engineered osteochondral composite scaffold and preparation method thereof

A technology of tissue engineering bone and composite scaffold, applied in tissue regeneration, medical science, prosthesis, etc., to achieve good biocompatibility, enhanced mechanical properties, biocompatibility and degradable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

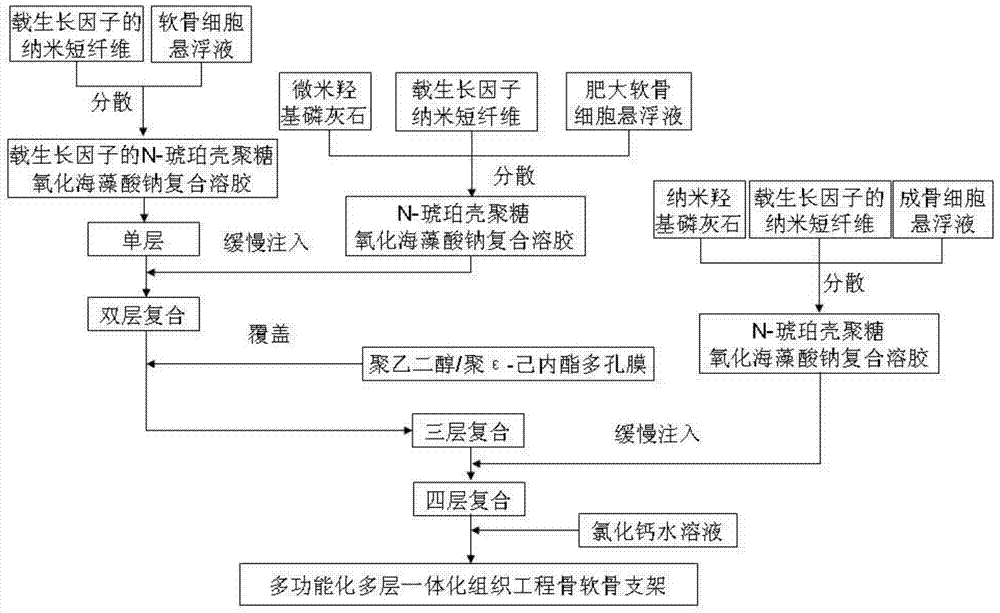

Method used

Image

Examples

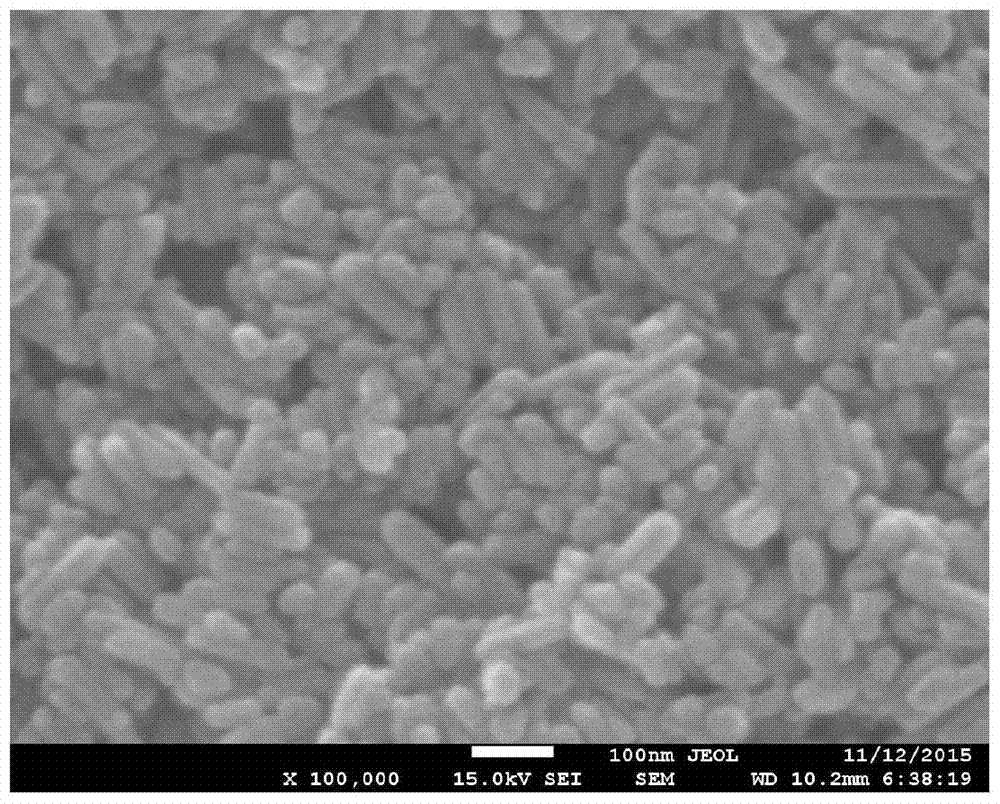

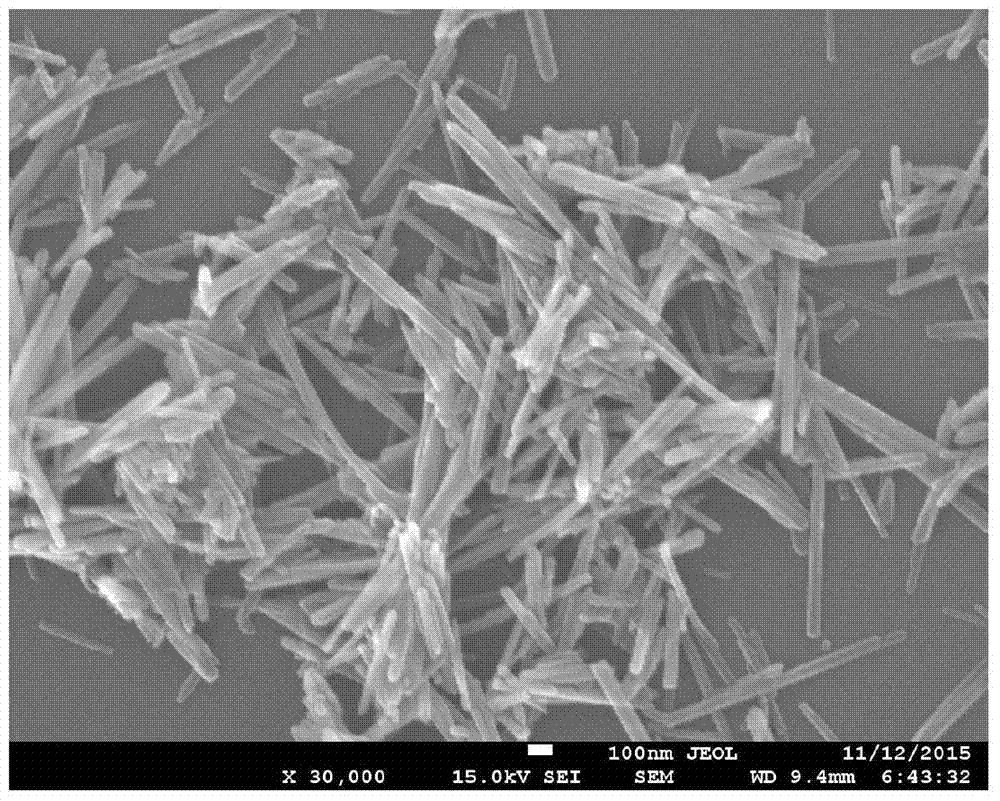

Embodiment 1

[0041] Accurately weigh 1.00g of polyε-caprolactone, add it into 5mL of chloroform, and prepare a 20w / v% solution, stir and dissolve evenly; accurately weigh 2.00g of polyethylene glycol, add 50ng of BMP-2 into 5mL of distilled water, and prepare into a 40w / v% solution, magnetically stirred to dissolve evenly. Inject into 5mL dry syringes respectively, the syringes are fixed in the card slot of the micro-injection pump, and the output end of the high-voltage DC power supply is fixed on the coaxial nozzle (the inner diameter of the outer needle is 1.1mm, the outer diameter of the inner needle is 0.6mm, and the inner diameter of the inner needle is 0.3 mm), the outer axis is polyε-caprolactone solution, and the flow rate is set at 0.5mL / h. The inner axis is polyethylene glycol solution, the flow rate is set to 0.1mL / h, and the DC high voltage is applied to 20kV. The high-speed rotating drum is used as the receiver (the speed is 1200r / min), and the distance between the coaxial no...

Embodiment 2

[0049] Accurately weigh 1.00g of polyε-caprolactone, add it into 5mL of chloroform, and prepare a 20w / v% solution, stir and dissolve evenly; accurately weigh 2.00g of polyethylene glycol, add 50ng of BMP-2 into 5mL of distilled water, and prepare into a 40w / v% solution, magnetically stirred to dissolve evenly. Inject into 5mL dry syringes respectively, the syringes are fixed in the card slot of the micro-injection pump, and the output end of the high-voltage DC power supply is fixed on the coaxial nozzle (the inner diameter of the outer needle is 1.1mm, the outer diameter of the inner needle is 0.6mm, and the inner diameter of the inner needle is 0.3 mm), the outer axis is polyε-caprolactone solution, and the flow rate is set to 0.5mL / h; the inner axis is polyethylene glycol solution, the flow rate is set to 0.1mL / h, and the DC high voltage is 20kV, which is rotated at a high speed. The roller is used as a receiver (rotating speed is 1200r / min), and the distance between the co...

Embodiment 3

[0057] Accurately weigh 1.00g of polyε-caprolactone, add it into 5mL of chloroform, and prepare a 20w / v% solution, stir and dissolve evenly; accurately weigh 2.00g of polyethylene glycol, add 50ng of BMP-2 into 5mL of distilled water, and prepare into a 40w / v% solution, magnetically stirred to dissolve evenly. Inject into 5mL dry syringes respectively, the syringes are fixed in the card slot of the micro-injection pump, and the output end of the high-voltage DC power supply is fixed on the coaxial nozzle (the inner diameter of the outer needle is 1.1mm, the outer diameter of the inner needle is 0.6mm, and the inner diameter of the inner needle is 0.3 mm), the outer axis is polyε-caprolactone solution, and the flow rate is set to 0.5mL / h; the inner axis is polyethylene glycol solution, the flow rate is set to 0.1mL / h, and the DC high voltage is 20kV, which is rotated at a high speed. The roller is used as a receiver (rotating speed is 1200r / min), and the distance between the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com