Method and device for realizing zero discharge of desulfurization wastewater

A technology for desulfurization wastewater and zero discharge, applied in chemical instruments and methods, gaseous effluent wastewater treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problems of large floor area, high heat loss, high investment cost, etc. Achieve the effects of small footprint, less equipment, and short process routes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

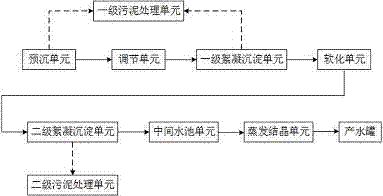

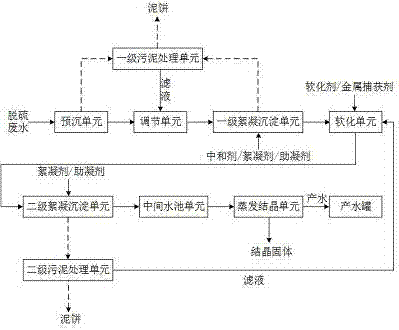

Method used

Image

Examples

Embodiment 1

[0073] Example 1 is a zero-discharge and resource-based treatment process for wet flue gas desulfurization wastewater from a power plant in Hebei, raw water Cl - , Ca 2 + , Mg 2+ , SO 4 2- , NO 3 - , SiO 2 , fluoride and suspended matter concentrations were 12000, 1618.5, 5380, 8000, 300, 250, 125 and 4000mg / L and contained a small amount of heavy metal ions. Ca in desulfurization wastewater after chemical softening and two-stage flocculation-sedimentation treatment 2+ , Mg 2+ , SiO 2 , fluoride, SO 4 2- The removal rates of suspended solids and suspended solids reached 98.6%, 96.9%, 93.5%, 88%, 90% and 99.5% respectively, meeting the water inlet requirements of the MVR evaporator. The effluent from the secondary flocculation and sedimentation unit enters the MVR evaporator for evaporation and crystallization, and the distilled water produced by the evaporator is Cl - and NO 3 - Fresh water with a concentration of less than 200 and 100mg / L is reused in the daily...

Embodiment 2

[0074] Example 2 is a zero-discharge and resource-based treatment process for wet flue gas desulfurization wastewater from a power plant in Hubei, raw water Cl - , Ca 2 + , Mg 2+ , SO 4 2- , NO 3 - , SiO 2 , fluoride and suspended matter concentrations are 16000, 1000, 4000, 4000, 250, 180, 100 and 3500 mg / L respectively and contain a small amount of heavy metal ions. Ca in desulfurization wastewater after chemical softening and two-stage flocculation-sedimentation treatment 2+ , Mg 2+ , SiO 2 , fluoride, SO 4 2- And the removal rate of suspended solids reaches 99%, 98%, 95%, 90%, 91% and 100% respectively, meeting the water inlet requirements of the MVR evaporator. The effluent from the secondary flocculation and sedimentation unit enters the MVR evaporator for evaporation and crystallization, and the distilled water produced by the evaporator is Cl - and NO 3 - Fresh water with a concentration of less than 300 and 100mg / L is reused in the daily production proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com