Acrylic acid acidized polyacrylate capable of realizing ultraviolet curing as well as preparation method and application of acrylic acid acidized polyacrylate

A technology of polyacrylate and butyl acrylate, which is applied in the field of polyacrylate preparation, can solve the problems of low mechanical strength and hardness, small volume shrinkage, poor acid and alkali resistance, etc., achieve outstanding effects, increase graft density, increase The effect of weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

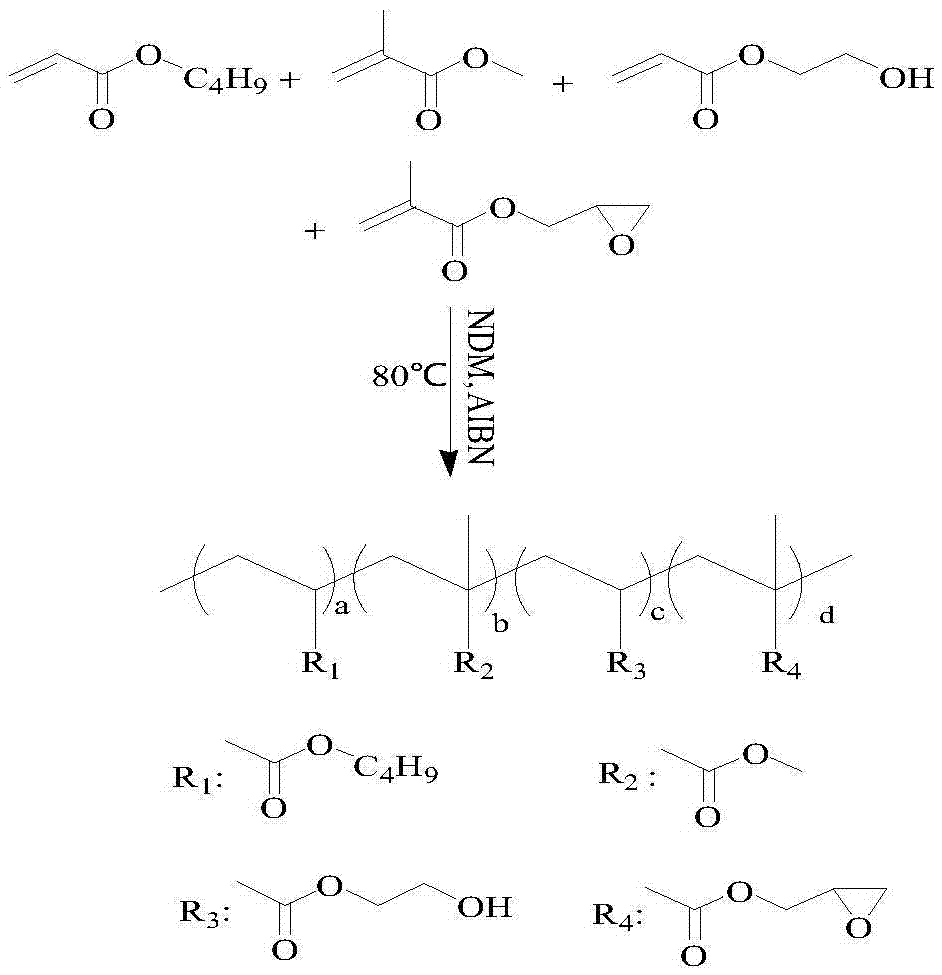

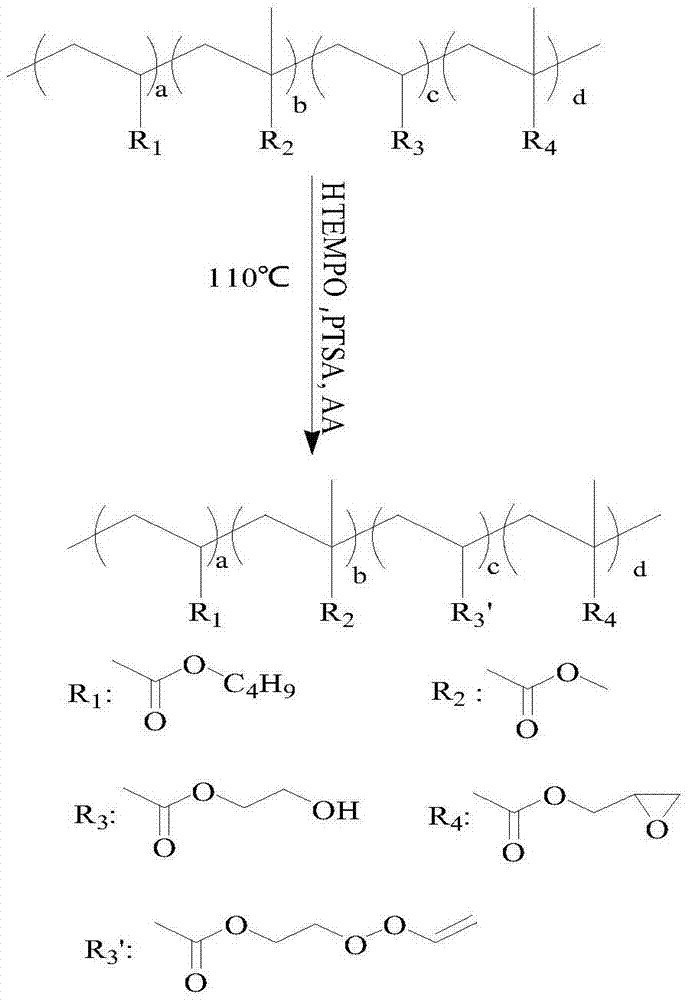

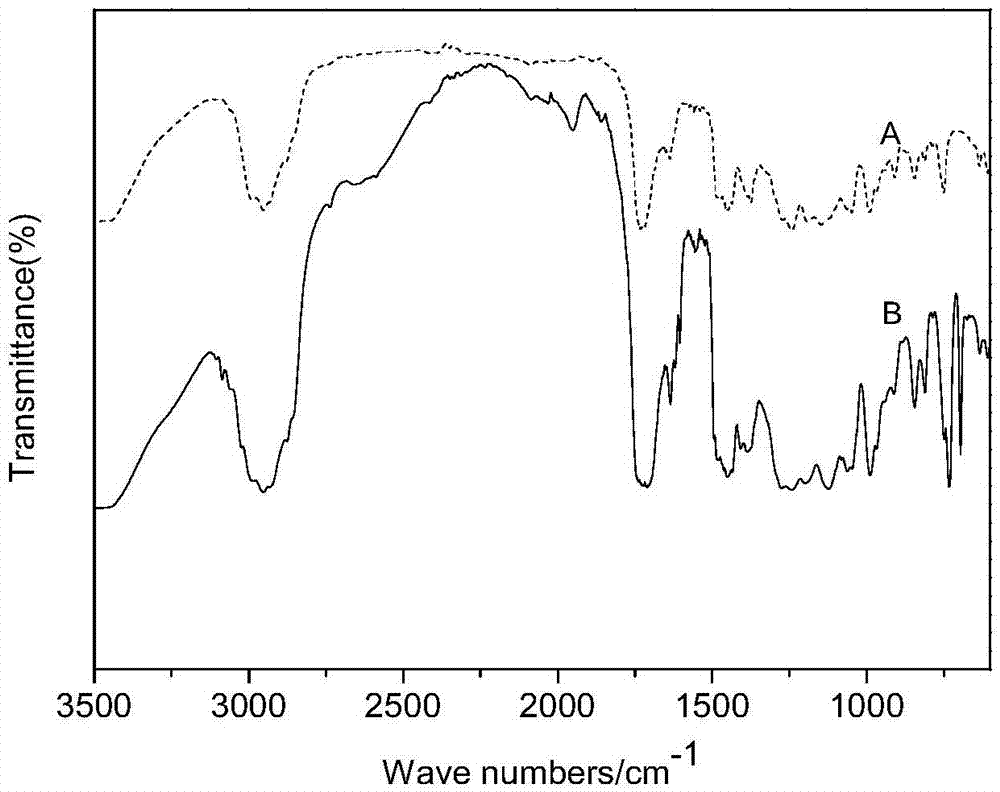

Method used

Image

Examples

Embodiment

[0041] 1. Treat 47g of MMA, 15g of BA, 19g of HEMA, and 19g of GMA with nitrogen bubbling for 30 minutes, and mix well; add 2g of chain transfer agent ethyl dodecyl mercaptan acetate, and mix well.

[0042] 2. Add the mixed solution accounting for 15% of the total mass of the mixed solution into a four-neck flask heated to 70° C., add 100 mL of ethyl acetate for mixing, and stir for 30 minutes.

[0043] 3. Add the remaining mixed solution into the constant pressure funnel, add it dropwise to the reaction solution of the second step, and react for 1.5 hours.

[0044] 4. Dissolve 4 g of azobisisobutyronitrile in 20 mL of ethyl acetate, add it to another constant pressure funnel, add dropwise to the reaction solution of the third step, and react for 2.5 hours.

[0045] 5. After the reaction is finished, cool the reaction product of step 4 to 50°C, put the material into the separatory funnel, add distilled water for extraction, let it stand for layering, collect the polyacrylate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com