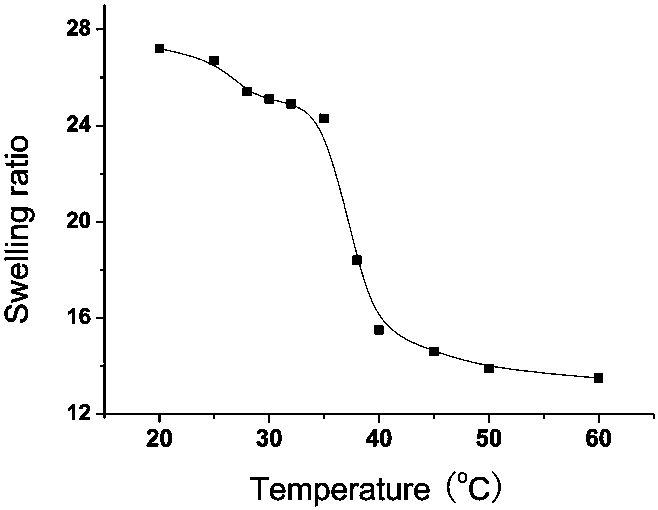

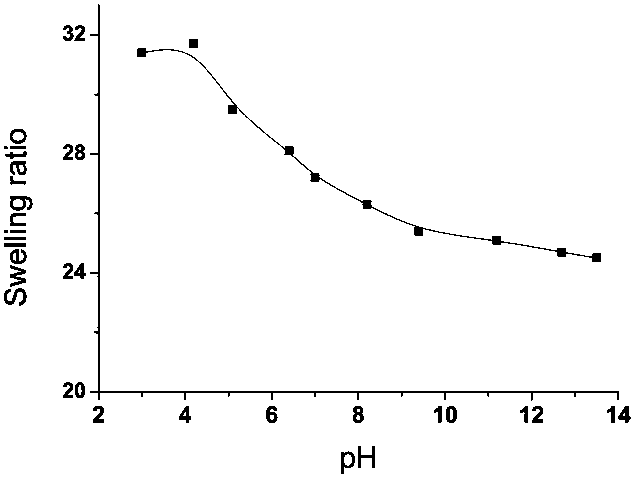

A kind of high-strength cellulose-based nanocomposite temperature, pH dual stimulus responsive gel and preparation method thereof

A cellulose-based, nano-composite technology, used in fiber processing, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of inability to human body environment, poor responsiveness, weak mechanical properties, etc., to ensure biocompatibility, Guarantee the effect of surface characteristics and strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 7.32g (N-isopropylacrylamide-N,N-dimethylaminoethyl methacrylate) copolymer, 0.27g 2-ethyl-4-methylimidazole, 1.2g eight-arm epoxypropyl cage silsesquioxane, dissolved in 50.6g of a mixed solution of DMF and THF with a mass ratio of 1:1, stirred at room temperature for 30 minutes to form a pre-spinning solution, and the pre-spinning solution was placed in a needle electrospinning device, The solution flow rate, voltage and spinning distance were set to 0.6 ml / h, 13 kV and 17 cm. After spinning, the responsive polymer nanofibers were heated to 160 degrees in a vacuum and dried for 4 hours before use;

[0044] (2) Dissolution of cellulose: prepare 6wt% NaOH 4wt% urea aqueous solution, then use G2 funnel to filter and use it as a cellulose solvent, weigh 400g of the solution, disperse 32.1g of cellulose in the solvent, and stir at room temperature for 5 minutes Put it in the refrigerator and freeze it for 12 hours. The frozen solid sample was thawed and stirred at room tem...

Embodiment 2

[0056] 11.56g (N-isopropylacrylamide-N,N-dimethylaminoethyl methacrylate) copolymer, 0.41g 2-ethyl-4-methylimidazole, 2.12g eight-arm epoxypropyl cage silsesquioxane, dissolved in 81.4g of a mixed solution of DMF and THF with a mass ratio of 1:1, stirred at room temperature for 30 minutes to form a pre-spinning solution, and the pre-spinning solution was placed in a needle electrospinning device, The solution flow rate, voltage and spinning distance were set to 0.6 ml / h, 13 kV and 17 cm. After spinning, the nanofibers were heated to 160 degrees in a vacuum and dried for 4 hours for later use;

[0057] (2) Dissolution of cellulose: prepare 6wt% NaOH 4wt% urea aqueous solution, then use G2 funnel to filter it as the cellulose solvent, weigh 600g solution, disperse 48.5g cellulose in the solvent, stir at room temperature for 5 minutes Put it in the refrigerator and freeze it for 12 hours. The frozen solid sample was thawed and stirred at room temperature, and finally a colorless ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com