A kind of high temperature low friction coefficient hard coating and preparation method thereof

A low friction coefficient, hard coating technology, applied in coating, metal material coating process, ion implantation plating and other directions, can solve the problems of wear resistance decline, limited application and other problems, achieve easy content, easy implementation, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

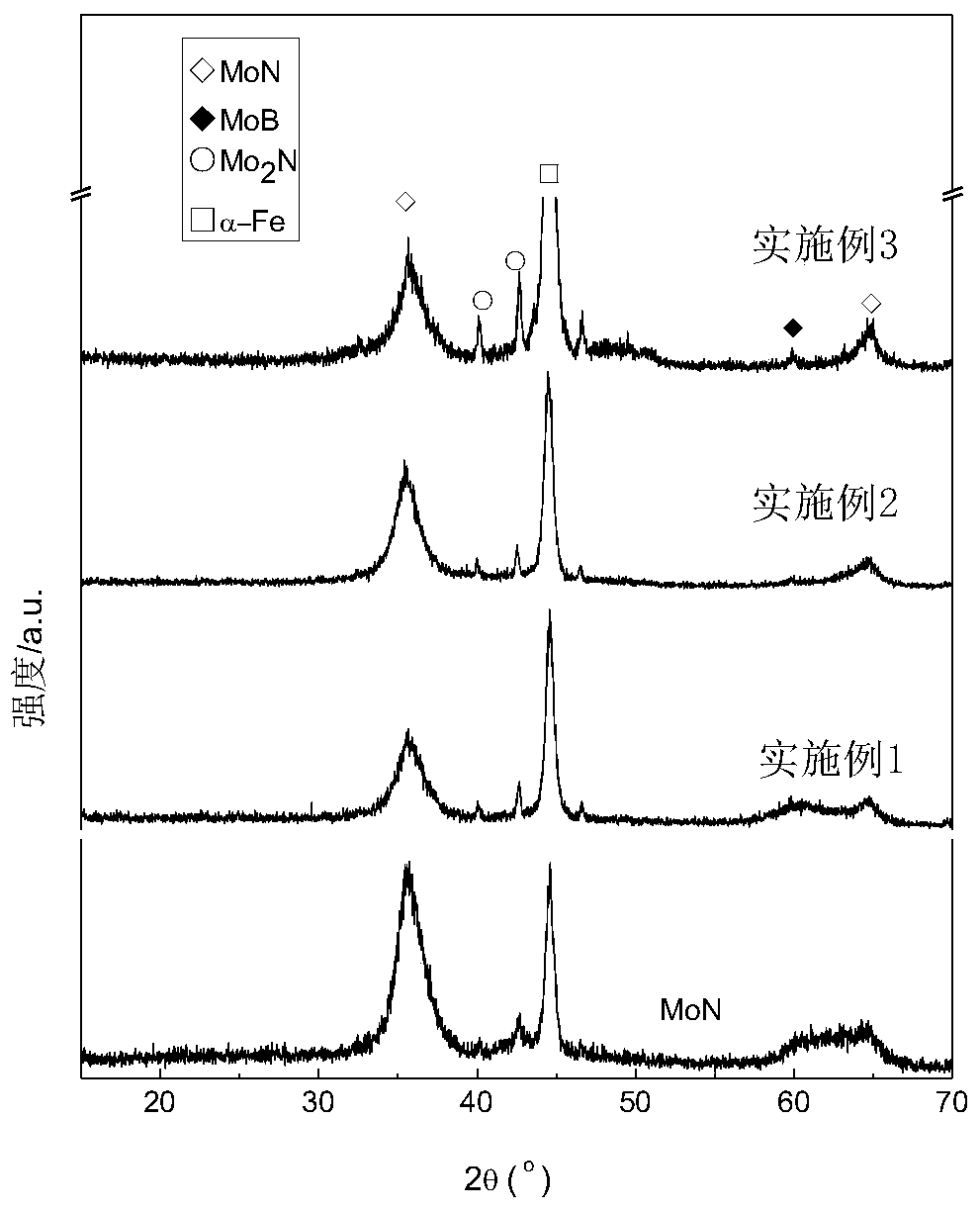

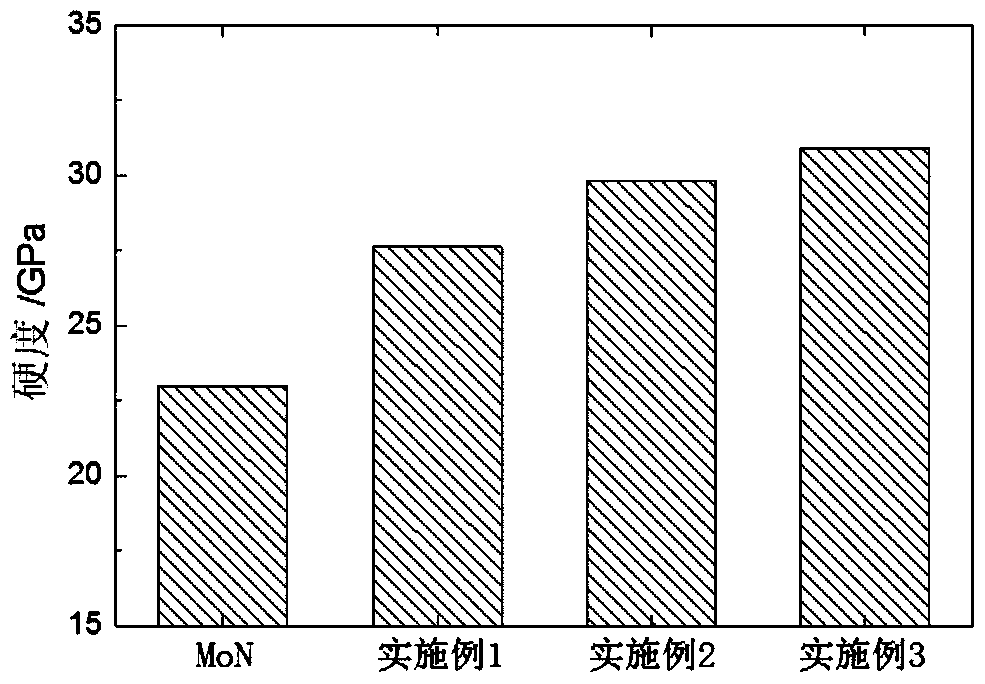

Examples

preparation example Construction

[0032] The specific steps of the preparation method of the high temperature low friction coefficient hard coating provided by the invention are:

[0033] 1) Use metal (steel, cast iron or hard alloy) or ceramics as the base, degrease, deoxidize, dry with hot air, and then fix it on the rotatable workpiece holder in the vacuum chamber;

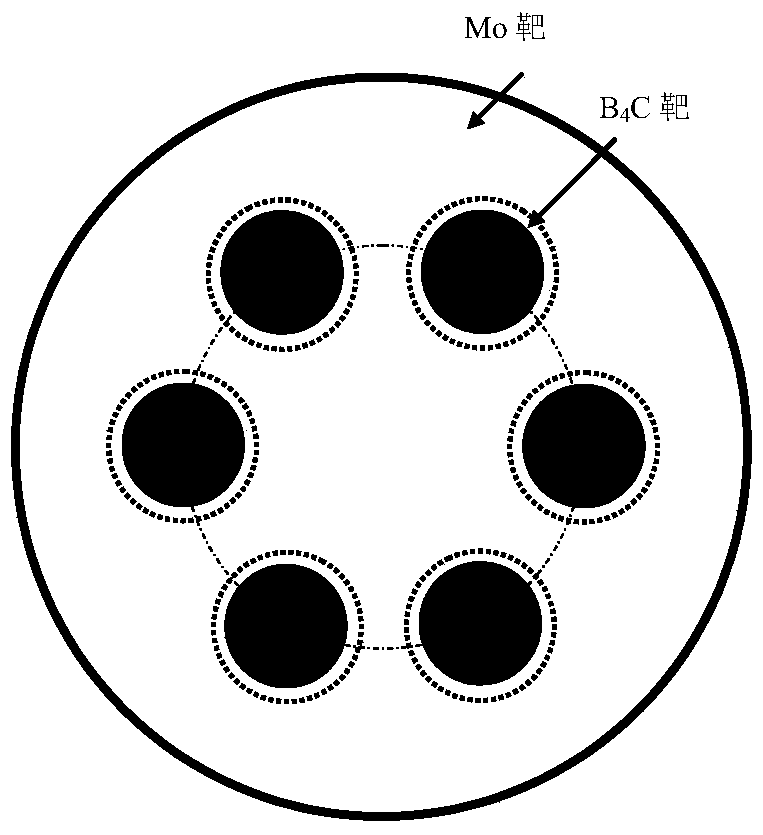

[0034] 2) Combine high-purity Mo and a certain amount of B 4 The composite target composed of C sheets is installed on the magnetron sputtering source; the metal Mo and B in the composite target 4 The area ratio of C is 20:1~2:1, the purity of Mo is 99.99%, B 4 The purity of C is 99.9%, and the distance between the composite target and the substrate is 80-120mm;

[0035] 3) Then pump the vacuum in the vacuum chamber to ≤5×10 -4 Pa, the flow rate is 20sccm Ar, when the vacuum chamber pressure is 0.3Pa, pre-sputtering Mo / B 4 C composite target 5min, pre-sputtering power is 150W;

[0036] 4) Then the ion source is fed with 6sccm argon gas, an...

Embodiment 1

[0041] 1) Will figure 1 Medium molybdenum target and 2 pieces of B 4 The composite target composed of C is used as the magnetron sputtering source, where B 4 The area ratio of C to Mo is 1:9, and the distance between the composite target and the substrate is 10cm;

[0042] 2) Select high-speed steel as the base material, derust and polish its surface, and clean it with acetone, alcohol and deionized water in an ultrasonic cleaner for 10 minutes respectively, then dry it with hot air and place it on the sample stage in the vacuum chamber;

[0043] 3) The vacuum degree in the vacuum chamber is pumped to ≤5×10 -4 After Pa, clean the surface of the substrate with argon ion beam sputtering for 10 min, ion energy 800eV, beam current density 10μA / cm 2 ;

[0044] 4) Introduce 4sccm argon and 20sccm nitrogen, the flow ratio is 1:5, and the working pressure is 1Pa to form a mixed atmosphere, using magnetron sputtering technology to sputter Mo and B 4 C composite target, energy 2000eV...

Embodiment 2

[0046] 1) Will figure 1 Medium molybdenum target and 4 pieces of B 4 The composite target composed of C is used as the magnetron sputtering source, where B 4 The area ratio of C to Mo is 1:4.5, and the distance between the composite target and the substrate is 10cm;

[0047] 2) Select high-speed steel as the base material, derust and polish its surface, and clean it with acetone, alcohol and deionized water in an ultrasonic cleaner for 10 minutes respectively, then dry it with hot air and place it on the sample stage in the vacuum chamber;

[0048] 3) The vacuum degree in the vacuum chamber is pumped to ≤5×10 -4 After Pa, clean the surface of the substrate with argon ion beam sputtering for 10 min, ion energy 800eV, beam current density 10μA / cm 2 ;

[0049] 4) Introduce 4sccm argon and 20sccm nitrogen, the flow ratio is 1:5, and the working pressure is 1Pa to form a mixed atmosphere, using magnetron sputtering technology to sputter Mo and B 4 C composite target, energy 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com