PPy/Fe3O4/reduced graphene oxide ternary composite wave-absorbing material and preparation method thereof

A composite wave absorbing material and technology of wave absorbing material, applied in the field of wave absorbing material, can solve the problems of poor wave absorbing performance, complicated preparation process, long preparation time, etc., and achieve light weight, simple preparation process and high wave absorption efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

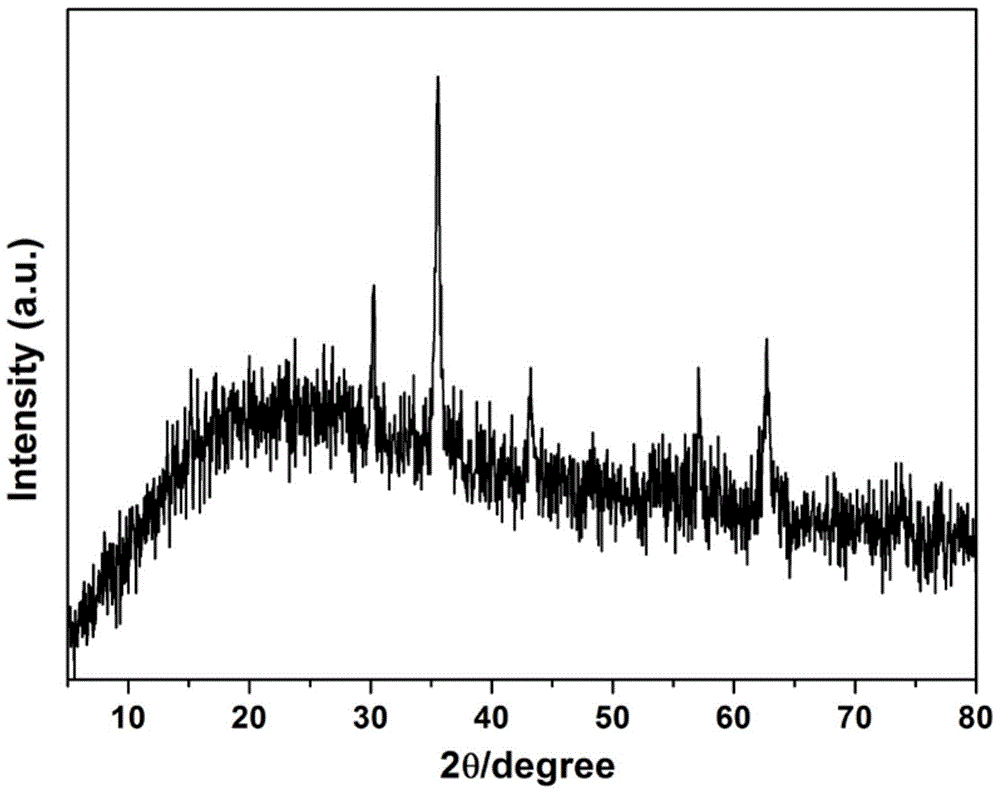

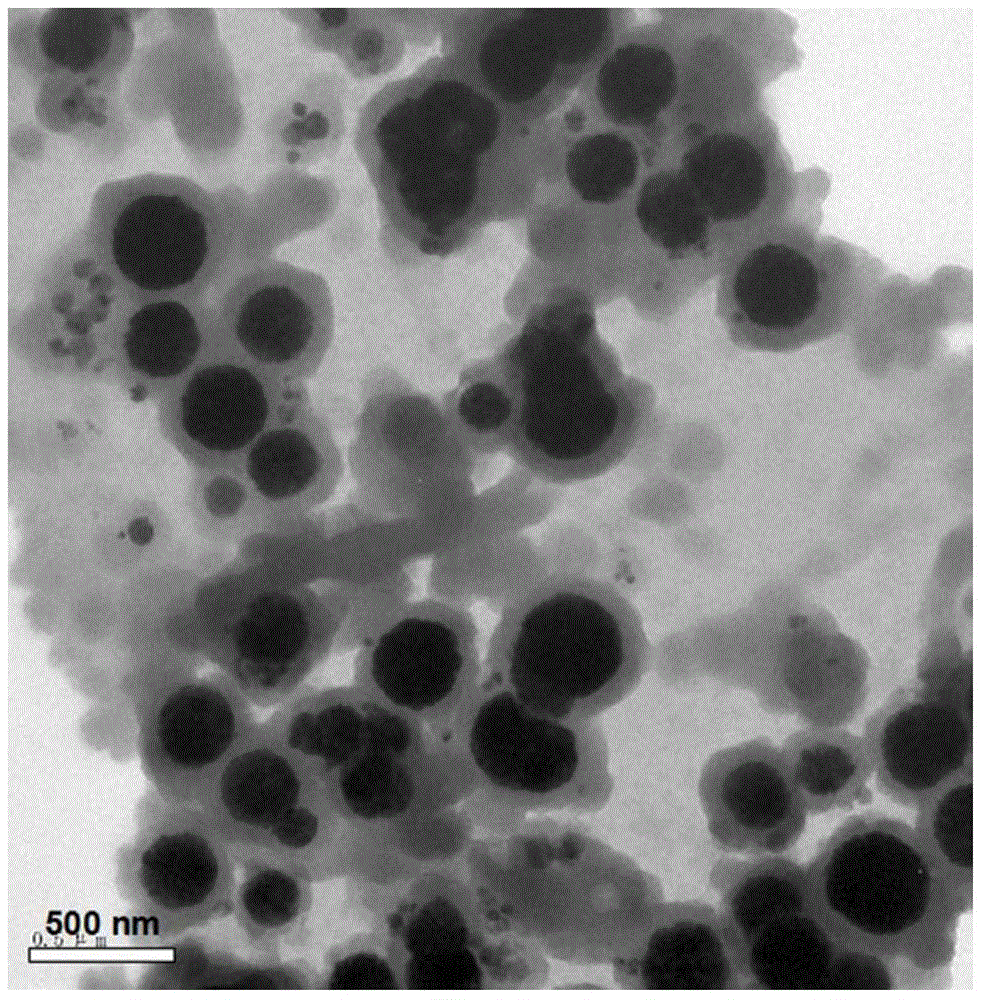

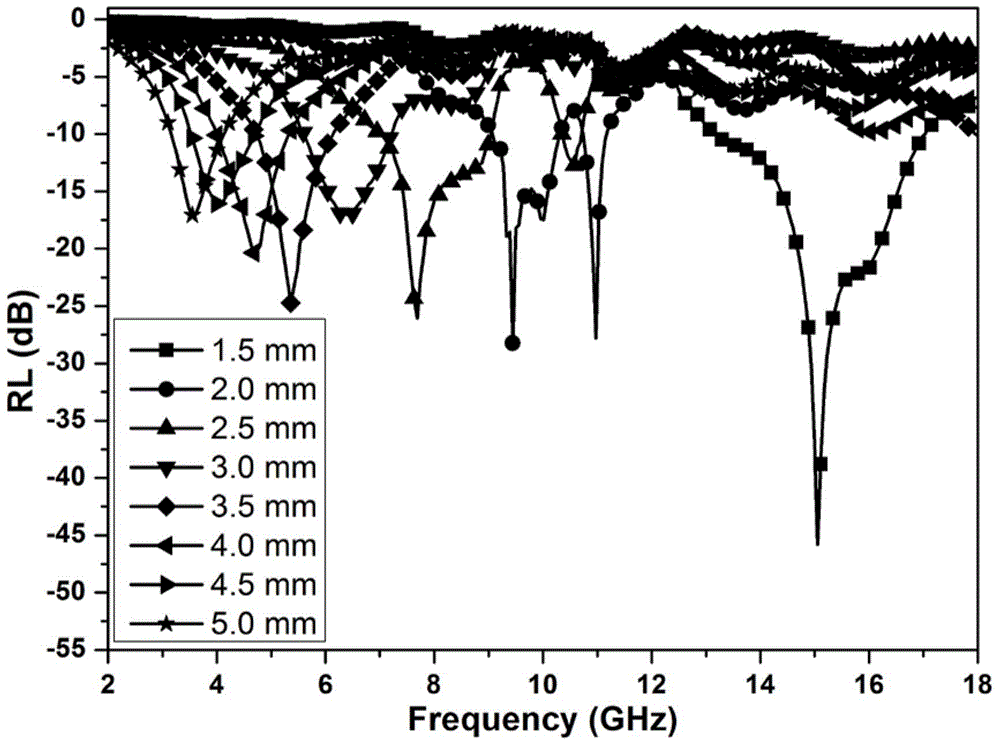

Embodiment 1

[0022] According to the mass ratio of graphite oxide and ferric chloride hexahydrate is 1:10.8, the mass ratio of graphite oxide and ethylene glycol is 1:1115, the molar ratio of graphite oxide and anhydrous sodium acetate is 1:72, weigh 0.05g graphite oxide and 0.54g of ferric chloride hexahydrate are dispersed in ethylene glycol by ultrasonic to form a mixed dispersion, then add 3.6g of anhydrous sodium acetate, stir to make it fully dissolve to form a mixed solution, transfer the mixed solution to a reaction kettle, and place it at 200 ℃ oven reaction for 10 h, after cooling to room temperature, the precipitate was washed several times with ethanol and deionized water, and then the obtained product was dried in a vacuum oven to obtain Fe 3 o 4 / Reduced graphene oxide composites. Press Fe 3 o 4 The mass ratio of / reduced graphene oxide solid powder to deionized water is 1:1429, Fe 3 o 4 The mass ratio of / reduced graphene oxide solid powder and sodium dodecylbenzenesulfo...

Embodiment 2

[0024] According to the mass ratio of graphite oxide and ferric chloride hexahydrate is 1:5.4, the mass ratio of graphite oxide and ethylene glycol is 1:1115, the molar ratio of graphite oxide and anhydrous sodium acetate is 1:60, weigh 0.05g graphite oxide and 0.27g of ferric chloride hexahydrate were dispersed in ethylene glycol by ultrasonic to form a mixed dispersion liquid, and then 3.0 g of anhydrous sodium acetate was added and stirred to fully dissolve to form a mixed liquid. Transfer the mixed solution into a reaction kettle, place it in an oven at 180°C for 12 hours, cool to room temperature, wash the precipitate with ethanol and deionized water several times, and then dry the obtained product in a vacuum oven to obtain Fe 3 o 4 / Reduced graphene oxide composites. Press Fe 3 o 4 The mass ratio of / reduced graphene oxide solid powder to deionized water is 1:1286, Fe 3 o 4 The mass ratio of / reduced graphene oxide solid powder and sodium dodecylbenzenesulfonate is ...

Embodiment 3

[0026] According to the mass ratio of graphite oxide and ferric chloride hexahydrate is 1:16.2, the mass ratio of graphite oxide and ethylene glycol is 1:1115, the molar ratio of graphite oxide and anhydrous sodium acetate is 1:80, weigh 0.05g graphite oxide and 0.81g of ferric chloride hexahydrate were dispersed in ethylene glycol by ultrasonic to form a mixed dispersion liquid, and then 4.0g of anhydrous sodium acetate was added and stirred to fully dissolve to form a mixed liquid. Transfer the mixed solution into a reaction kettle, put it in an oven at 220°C for 8 hours, and wash the precipitate with ethanol and deionized water several times after cooling to room temperature, and then dry the obtained product in a vacuum oven to obtain Fe 3 o 4 / Reduced graphene oxide composites. Press Fe 3 o 4 The mass ratio of / reduced graphene oxide solid powder to deionized water is 1:1571, Fe 3 o 4 The mass ratio of / reduced graphene oxide solid powder and sodium dodecylbenzenesulf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com