Polylactic acid-based thermoplastic resin composition and molded article thereof

A thermoplastic resin and polylactic acid resin technology, which is applied in the field of polylactic acid-based thermoplastic resin compositions, can solve the problems of non-conformity and longer molding time, and achieve the effects of good heat resistance, reduced environmental load, and short molding cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

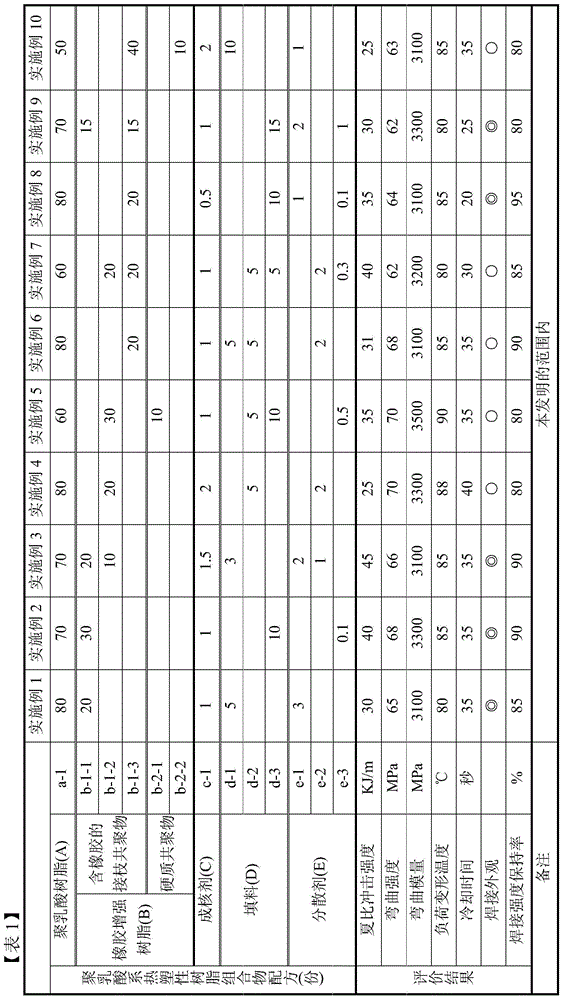

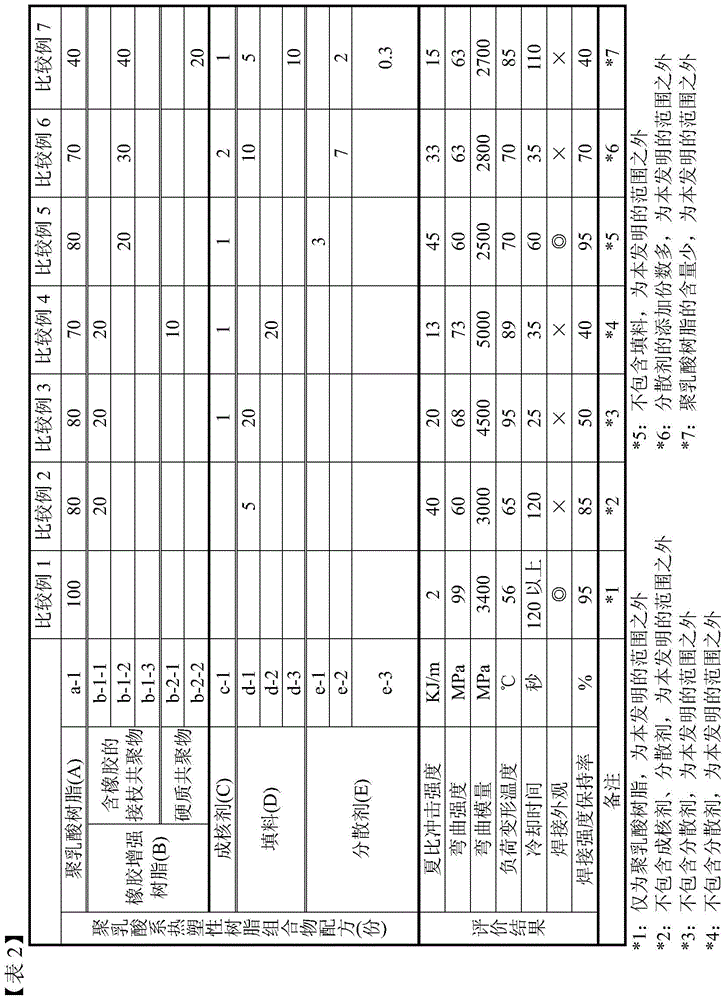

Examples

Synthetic example 1

[0118]

[0119] The rubber-containing graft copolymer was synthesized by emulsion polymerization according to the following recipe.

[0120] [formula]

[0121] Styrene (ST): 25 parts

[0122] Acrylonitrile (AN): 10 parts

[0123] Polybutadiene latex: 65 parts (based on solid content)

[0124] Potassium disproportionated abietate: 1 part

[0125] Potassium hydroxide: 0.03 parts

[0126] Tertiary dodecyl mercaptan (t-DM): 0.04 parts

[0127] Cumyl hydroperoxide: 0.3 parts

[0128] Ferrous sulfate: 0.007 parts

[0129] Sodium pyrophosphate: 0.1 parts

[0130] Crystalline glucose: 0.3 parts

[0131] Distilled water: 190 parts

[0132] Put distilled water, disproportionated potassium rosinate, potassium hydroxide and polybutadiene latex (gel content 80% by weight, average particle size 0.3μm) into the autoclave, after heating to 60°C, add ferrous sulfate and sodium pyrophosphate , Crystalline glucose. ST, AN, t-DM, and cumene hydroperoxide were continuously added over ...

Synthetic example 2

[0133]

[0134] In the raw material formulation of Synthesis Example 1, 50 parts (in terms of solid content) of polybutadiene (average particle diameter: 0.3 μm) with a gel content of 97% by weight were used as a rubbery polymer, and styrene as a monomer Except having reacted 37 parts of (ST) and 13 parts of acrylonitrile (AN), graft polymerization was performed similarly to the synthesis example 1, and the ABS graft copolymer (b-1-2) was obtained.

Synthetic example 3

[0135]

[0136] In the raw material formulation of Synthesis Example 1, 60 parts (calculated as solid content) of polybutyl acrylate (gel content 65% by weight, average particle diameter 0.34 μm) were used as a rubbery polymer, and methacrylic acid as a monomer Except having reacted 36 parts of methyl esters (MMA) and 4 parts of methyl acrylates (MA), graft polymerization was performed similarly to the synthesis example 1, and the graft copolymer (b-1-3) was obtained.

[0137] The measurement results of the rubber content, the weight composition ratio of the monomers, the graft ratio, and the weight-average molecular weight of the acetone-soluble component of the rubber-containing graft copolymers produced in Synthesis Examples 1, 2, and 3 are as follows.

[0138] Rubber-containing graft copolymer (b-1-1):

[0139] Rubber content = 66.2% by weight

[0140] AN / ST=28 / 72

[0141] Graft rate = 40% by weight

[0142] Weight average molecular weight (Mw) = 154000

[0143] Rubb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com