Water-soluble organic silicone modified polyester resin as well as preparation method and application thereof

A technology for modifying polyester and organosilicon, which is applied in the direction of polyester coatings and coatings, which can solve the problems of adverse effects on environmental construction personnel and achieve the effects of simple and easy preparation process, reduced cost and reduced damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

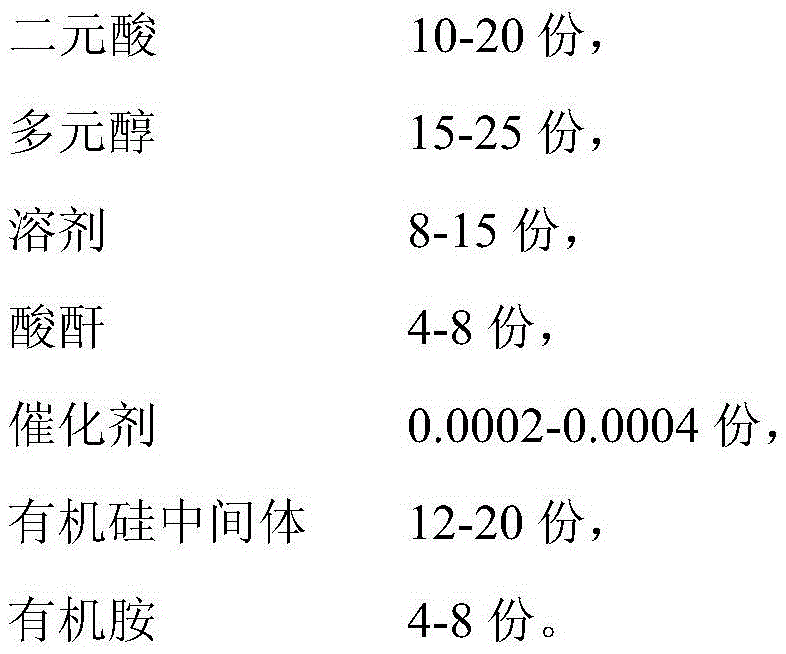

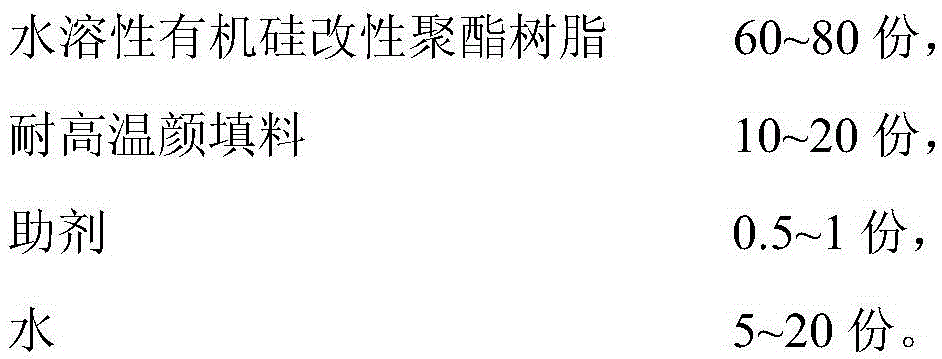

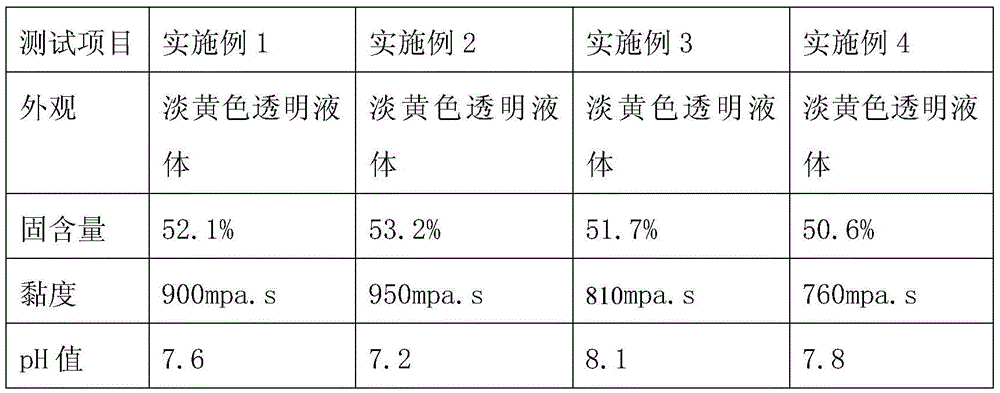

[0030] Embodiment 1: Preparation of water-soluble silicone modified polyester resin

[0031] Put 16 parts of neopentyl glycol, 4 parts of trimethylolpropane, 9 parts of adipic acid, and 5 parts of phthalic anhydride into a reaction kettle with a water separator and stirring, start stirring after melting, and continue to heat up to 160°C. After 6 hours of esterification at heat preservation, continue to raise the temperature to 260°C, keep the xylene at reflux during the reaction process, take out the generated water in time, and react until the acid value is below 10mgKOH / g. Cool down to 190°C, add 14 parts of solvent propylene glycol methyl ether acetate and 5 parts of trimellitic anhydride, react until the acid value is 80 mgKOH / g, then cool down to 130°C, add 0.00038 parts of aluminum acetylacetonate and 16 parts of Corning's 3037, react for 2 hours until transparent , lower the temperature to 90°C, add 6 parts of AMP-95, and neutralize for 30 minutes. Finally, 24 parts of...

Embodiment 2

[0034] Embodiment 2: Preparation of water-soluble organosilicon-modified polyester resin

[0035] Put 15 parts of 1,5-pentanediol, 10 parts of trimethylolpropane, 11 parts of adipic acid, and 9 parts of isophthalic acid into a reaction kettle with a water separator and stirring, and start stirring after melting. Continue to raise the temperature to 200°C, keep warm for 2 hours after esterification, then continue to raise the temperature to 240°C, keep the xylene under reflux during the reaction, take out the generated water in time, and react until the acid value is below 10mgKOH / g. Cool down to 160°C, add 11 parts of solvent ethylene glycol butyl ether and 8 parts of trimellitic anhydride, react until the acid value is 60mgKOH / g, then cool down to 100°C, add 0.0002 parts of aluminum acetylacetonate, 0.0002 parts of aluminum metachlorate and 12 parts of Shin-Etsu KR-510, react for 1h until transparent, cool down to 95°C, add 4 parts of AMP-95, and neutralize for 30min. Finall...

Embodiment 3

[0038] Embodiment 3: Preparation of water-soluble silicone modified polyester resin

[0039]Put 10 parts of 1,4-cyclohexanedimethanol, 5 parts of trimethylolethane, 3 parts of pimelic acid, and 9 parts of 1,4-cyclohexanedicarboxylic acid into the reaction with water separator and stirring In the kettle, start stirring after melting, continue to heat up to 170°C, keep warm for esterification for 4 hours, continue to heat up to 200°C, keep the xylene in reflux during the reaction, take out the generated water in time, and react until the acid value is 10mgKOH / Below g is enough. Lower the temperature to 170°C, add 15 parts of solvent propylene glycol methyl ether and 7 parts of pyromellitic anhydride, and react until the acid value is 90 mgKOH / g. Cool down to 100°C, add 0.0002 parts of sodium metaaluminate and 16 parts of Wacker IC678, react for 2 hours until transparent, then cool down to 85°C, add 7 parts of YT-99, and neutralize for 30 minutes. Finally, add water to dilute ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com