Method for increasing S-adenosyl-L-methionine yield by saccharomyces cerevisiae genetic engineering

A technology of Saccharomyces cerevisiae and genetic engineering, which is applied in the field of microbial technology and metabolic engineering, can solve problems such as unsatisfactory, and achieve the effects of improving knockout efficiency, excellent food safety biological performance, and excellent fermentation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

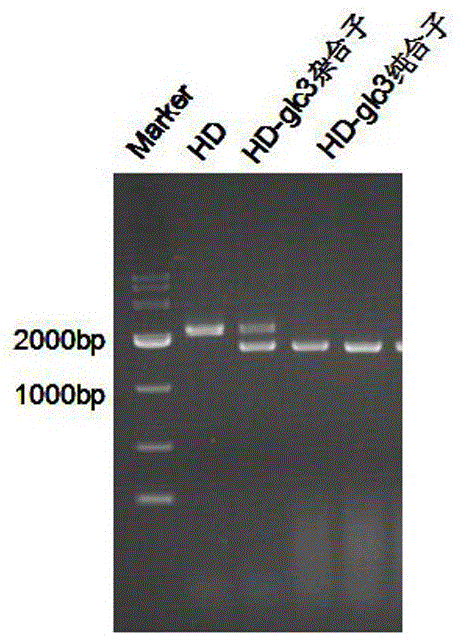

[0032] Example 1: Taking the diploid Saccharomyces cerevisiae strain HD as an example, a heterozygote for GLC3 gene knockout was constructed.

[0033] 1. Construction of the knockout box by PCR. The method is as follows: use the plasmid pUG6 as a template, and use primers to perform PCR reactions on GLC3-up and GLC3-down. The PCR products are purified and recovered with a DNA purification kit, confirmed by DNA electrophoresis, and finally used as a knockout frame for GLC3 gene knockout.

[0034] 2. LiAC conversion. The method is as follows: Pick a single colony of the original strain HD and place it in a 20mLYPD shake flask at a speed of 200rpm, culture overnight at 30°C, then transfer 2mL to a 50mLYPD shake flask and continue to culture for 3-4 hours, OD 600 The cells were collected by centrifugation at about 1 hour. Wash once with 20mL sterile water, centrifuge, remove the supernatant; wash again with 0.1M LiAC, centrifuge, remove the supernatant; resuspend the bacteria wi...

Embodiment 2

[0036] Example 2: Taking diploid Saccharomyces cerevisiae strain HD as an example, spore haploids were isolated and knockout homozygotes were obtained.

[0037] The method is as follows: Spread the knockout heterozygote obtained in Example 1 on the McFarland sporulation medium (glucose 1g / L, KCl 1.8g / L, sodium acetate 8.2g / L and agar 15g / L) and culture for 3-4 On the next day, the spore yield was confirmed to be over 95% under a microscope; collect a small amount of spores, add 400 μL of helicase reaction solution (from Shanghai Sangong Yeast Genome Extraction Kit), suspend the spores, then add 10 μl of helicase solution, and place in a water bath at 37°C 3h; centrifuge, resuspend with 500μL sterile water, then 100W ultrasonic vibration treatment for 5s, 7s intermittent, 5 cycles of oscillation; finally, confirm under the microscope that the spores are relatively fully separated (separation rate greater than 80%), and take a small amount with an inoculation loop The bacterial so...

Embodiment 3

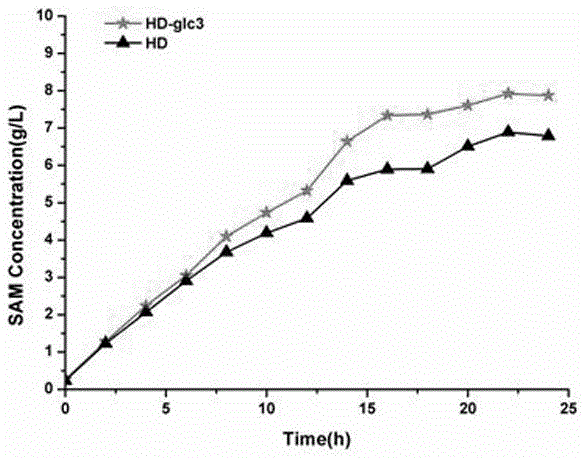

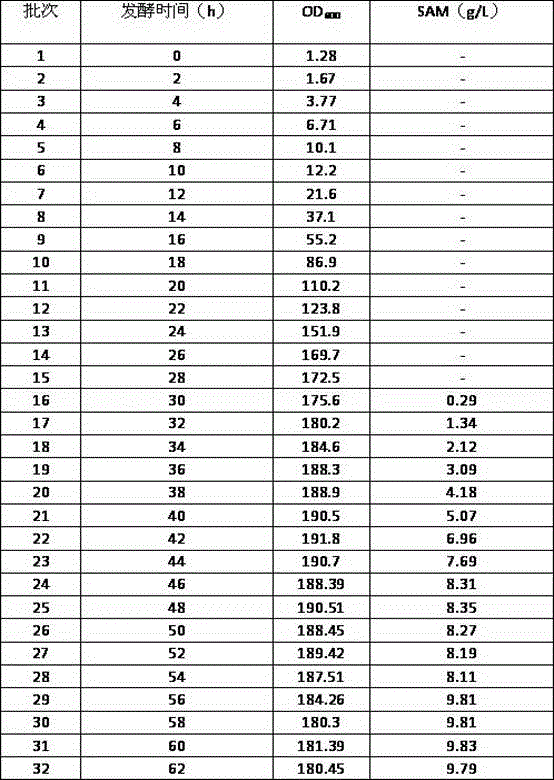

[0038] Example 3: Taking diploid Saccharomyces cerevisiae strain HD and HD-glc3 strain with GLC3 gene mutation as an example, SAM was produced by fermentation. Methods as below:

[0039] 1. Inoculate HD and HD-glc3 into 50mL LYPD liquid medium respectively, and after cultivating on a constant temperature shaker at 200rpm and 30°C for 18 hours, transfer them to several 50mLYPD shake flasks, transfer 3mL to each shake flask, and continue to cultivate for 12 hours, as the seed liquid of the fermenter.

[0040] 2. After the 10L fermenter has been sterilized to confirm that the fermenter has good performance, add 7L of SAM-producing fermentation medium, sterilize at 115°C for 30 minutes, and then cool and control the temperature to 30°C; the composition of the SAM-producing fermentation medium is as follows: 10g / L glucose , 3g / L yeast powder, 5g / L (NH 4 ) 2 SO 4 , 10g / LKH 2 PO 4 , 3g / LMgSO 4 , 0.1g / LMnSO 4 ·7H 2 O, 0.6g / LZnSO 4 ·7H 2 O, 0.55g / LFeSO 4 , 0.5g / LNaCl, 0.5g / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com