Method for preparing super-hydrophobic copper surface by combining electro-deposition with CVD

An electrodeposition and combination technology, applied in the field of preparation of superhydrophobic surfaces, can solve the problems of restricting the practical application of metal surfaces, time-consuming, cumbersome and other problems, and achieve the effect of excellent superhydrophobic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Copper sheet pretreatment

[0029] Put the copper sheet into anhydrous acetone, absolute ethanol and deionized aqueous solution in turn, and perform ultrasonic cleaning, each cleaning time is 10~20min; The slices were mechanically polished.

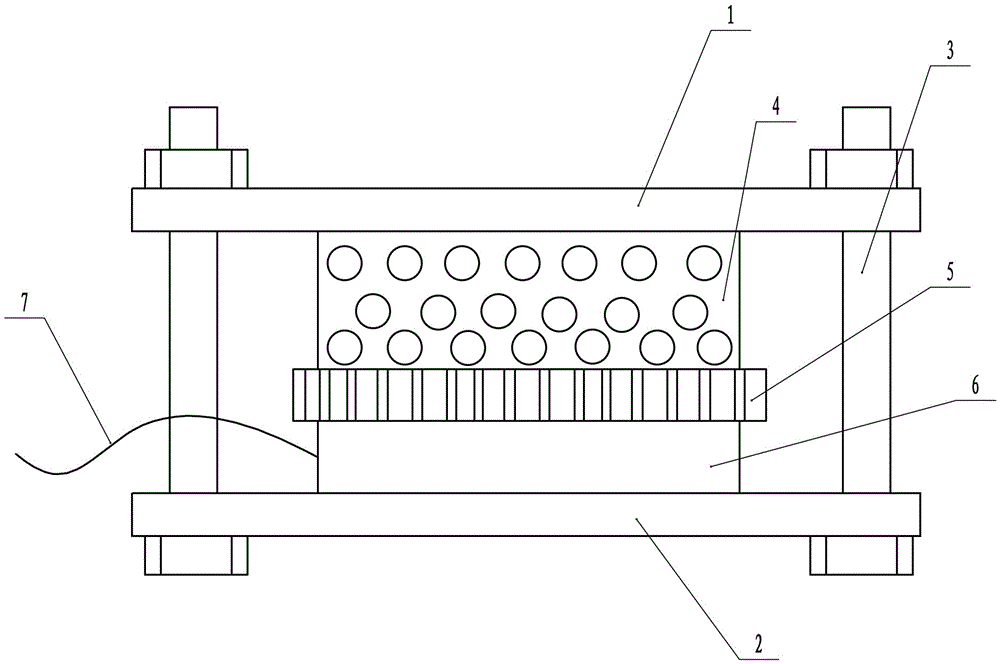

[0030] (2) Electrodeposition reaction

[0031] Connect the copper sheet treated in step (1) with the anodized aluminum template using a clamp, such as figure 1 As shown, the upper splint 1 is arranged on the upper part of the lower splint 2, the porous glass 4, the anodized aluminum template 5 and the copper sheet 6 are arranged from top to bottom and placed between the upper splint 1 and the lower splint 2, and the upper splint 2 is fixed by bolts 3. Press between the splint 1 and the lower splint 2, the copper sheet 6 is provided with a wire 7, the copper sheet is used as the cathode, and the platinum electrode is used as the anode to contain 350g / LNiSO 4 , 50g / LNiCl 2 ·6H 2 O and 450g / LH 3 BO 3 The nickel ion solution...

Embodiment 2

[0038] (1) Copper sheet pretreatment

[0039] Put the copper sheet into acetone solution, ethanol solution and deionized water solution in turn, and perform ultrasonic cleaning, each cleaning time is 10~20min; Mechanically polished.

[0040] (2) Electrodeposition reaction

[0041] Connect the copper sheet treated in step (1) with a commercial anodized aluminum template using a fixture, such as figure 1 As shown, the upper splint 1 is arranged on the upper part of the lower splint 2, the porous glass 4, the commercial anodized aluminum template 5 and the copper sheet 6 are arranged from top to bottom and placed between the upper splint 1 and the lower splint 2, and the Press between the upper splint 1 and the lower splint 2, the copper sheet 6 is provided with a wire 7, the copper sheet is used as the cathode, and the platinum electrode is used as the anode to contain 300g / LNiSO 4 , 100g / LNiCl 2 ·6H 2 O and 400g / LH 3 BO 3 The nickel ion solution was used as the electroly...

Embodiment 3

[0048] (1) Copper sheet pretreatment

[0049] Put the copper sheet into acetone solution, ethanol solution and deionized water solution in turn, and perform ultrasonic cleaning, each cleaning time is 10~20min; Mechanically polished.

[0050] (2) Electrodeposition reaction

[0051] Connect the copper sheet treated in step (1) with a commercial anodized aluminum template using a fixture, such as figure 1 As shown, the upper splint 1 is arranged on the upper part of the lower splint 2, the porous glass 4, the commercial anodized aluminum template 5 and the copper sheet 6 are arranged from top to bottom and placed between the upper splint 1 and the lower splint 2, and the Press between the upper splint 1 and the lower splint 2, the copper sheet 6 is provided with a wire 7, the copper sheet is used as the cathode, and the platinum electrode is used as the anode to contain 320g / LNiSO4 , 75g / LNiCl 2 ·6H 2 O and 500g / LH 3 BO 3 The nickel ion solution was used as the electrolyte,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com