Grating preparation method through pattern transfer based on nano-imprint

A pattern transfer and nano-imprint technology, applied in diffraction grating, patterned surface photoengraving process, optics, etc., can solve the problems of complex process, uncertainty of microstructure pattern, high preparation cost, and achieve optimized preparation process, The effect of easy industrial production and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

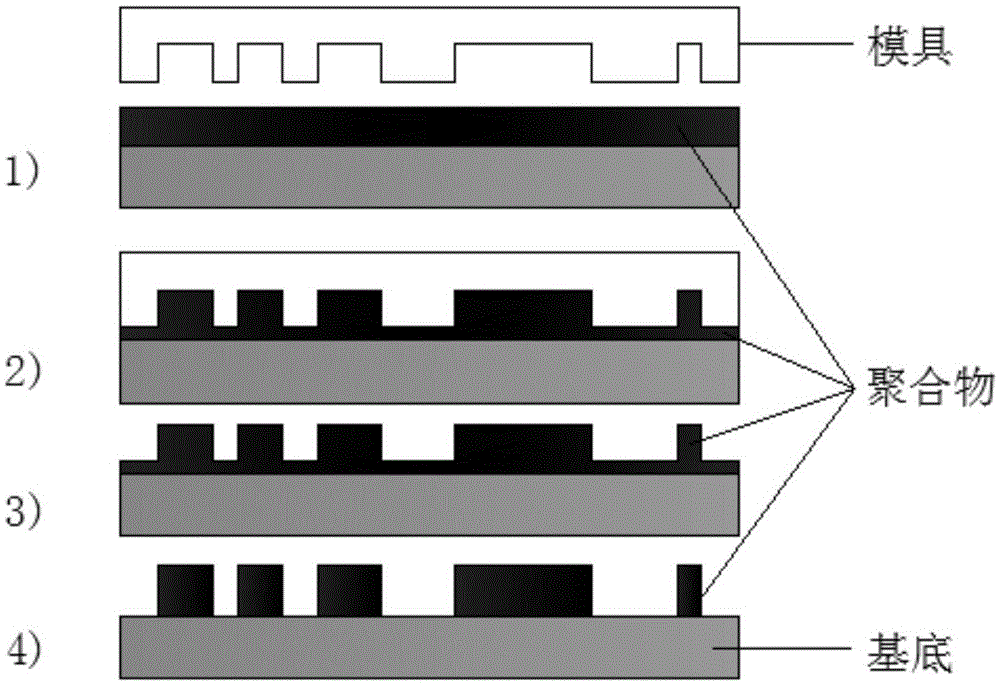

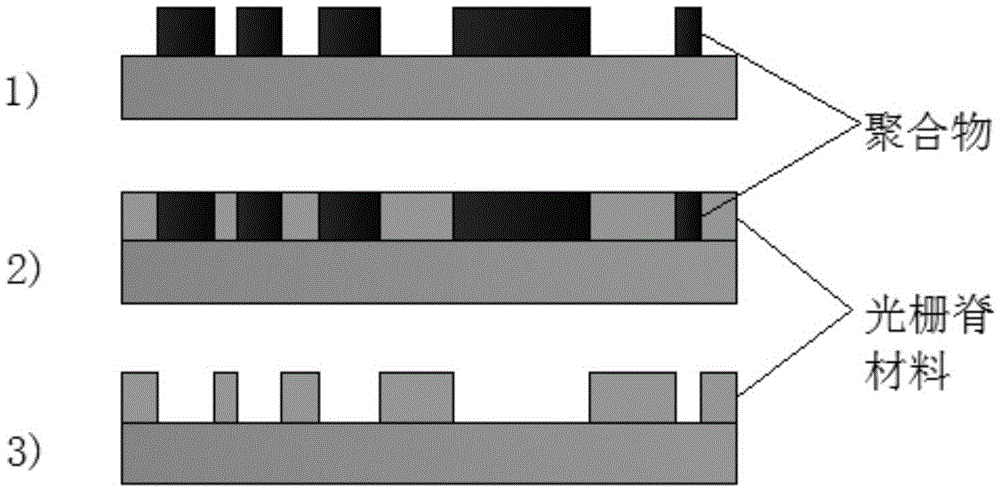

Method used

Image

Examples

Embodiment 1

[0026] Step 1): Take a substrate with a clean and smooth upper surface as the substrate for spin-coating polymer photoresist. The material of the substrate can be K9 glass or fused silica, and the shape of the substrate can be round or square. In this embodiment, a circular K9 glass with a diameter of 30mm is used as the substrate, and the pre-coated polymer surface is carefully wiped three times with acetone. After the acetone is naturally volatilized and dried, it is placed in the center of a CT62 plastic rejection table from KarlSuss, Germany. Turn on the hydraulic nitrogen to suck the substrate on the platform, drop 3 drops of polymer (PMMA) solvent into the center of the substrate, set the rotation speed to 3500r / min, and the time to 30s. The thickness of the polymer film spin-coated under this setting is about 350nm . Close the rotary cover and turn on the rotary table. After the gluing is finished, take out the substrate, put it into the oven of Heraeus Company in Germ...

Embodiment 2

[0031] Step 1): Take a round fused silica with a clean and smooth upper surface and a diameter of 30mm as the substrate, carefully wipe the pre-coated polymer surface with acetone three times, and after the acetone evaporates and dries naturally, put it into a CT62 type thrower from KarlSuss Company, Germany. Rubber table center. Turn on the hydraulic nitrogen to suck the substrate on the platform, drop 3 drops of polymer (PS) solvent into the center of the substrate, set the rotation speed to 3000r / min, and the time to 30s. The thickness of the polymer film spin-coated under this setting is about 400nm . Close the rotary cover and turn on the rotary table. After the gluing is finished, take out the substrate, put it into the oven of Heraeus Company in Germany for drying, set the oven temperature to 90°C, and bake for 30 minutes. Quartz substrate.

[0032] Step 2): Select a rectangular silicon nitride with a clean and smooth surface of 10mmx10mm as the stamper template mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spin coating thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com