Graphite anode material for lithium-ion battery and preparation method of graphite anode material

A lithium-ion battery and graphite negative electrode technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of high cost and low yield in large-scale production, and achieve the effects of low price, abundant sources, and excellent rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

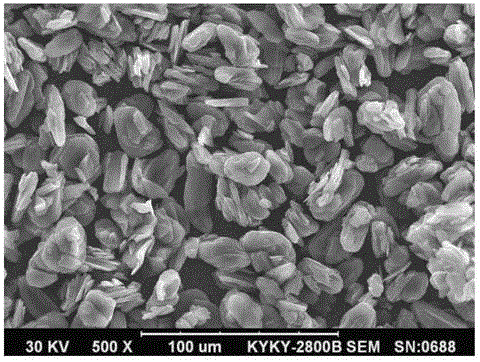

[0035] Petroleum coke with a fixed carbon mass content greater than or equal to 99.5% is crushed by a 70 machine, shaped by a ball mill, and sieved to obtain a particle size distribution of D10 greater than or equal to 2 microns, D50 of 8-10 microns, D90 of 30 microns or less, and an aspect ratio of 3 The primary particle between -15; Take by weighing this primary particle of 100 parts of quality, the asphalt of 5 parts of quality, the ferric oxide of 1 part of quality, the carbon tetrachloride of 5 parts of quality, be placed in high-temperature reactor, inert Under the protection of the atmosphere, heat and stir, among which 300 ° C for 6 hours, 600 ° C for 6 hours, and then cool and discharge; the material after granulation is graphitized at 3400 ° C for 10 hours, and the final product is obtained after classification or sieving (SEM diagram see figure 1 ).

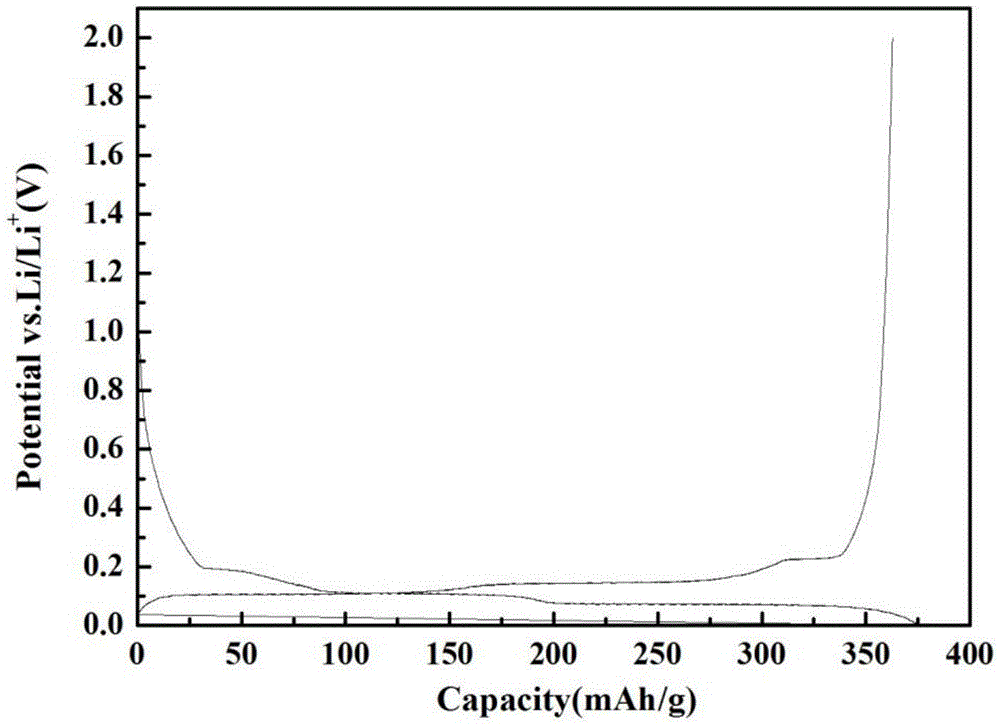

[0036] Active material (prepared graphite material), conductive agent (superP carbon black), sodium carboxymethyl ce...

Embodiment 2

[0039]Petroleum coke with a fixed carbon mass content greater than or equal to 99.5% is crushed by a 70 machine, shaped by a ball mill, and sieved to obtain a particle size distribution of D10 greater than or equal to 2 microns, D50 of 8-10 microns, D90 of 30 microns or less, and an aspect ratio of 3 The primary particle between -15; Take this primary particle of 100 parts of quality, the bitumen of 15 parts of quality, the ferric oxide of 5 parts of quality, the carbon tetrachloride of 15 parts of quality, be placed in high-temperature reactor, inert Under the protection of the atmosphere, heat and stir, among which 300 ° C for 6 hours, 800 ° C for 6 hours, then cool and discharge; the material after granulation is graphitized at 2600 ° C for 48 hours, and the final product is obtained after classification or sieving.

[0040] Its charge and discharge capacity is 358.2mAh / g, the initial efficiency is 95.7%, and the 100-cycle cycle capacity retention rate is 99.09% (the button ...

Embodiment 3

[0042] Petroleum coke with a fixed carbon mass content greater than or equal to 99.5% is crushed by a 70 machine, shaped by a ball mill, and sieved to obtain a particle size distribution of D10 greater than or equal to 2 microns, D50 of 8-10 microns, D90 of 30 microns or less, and an aspect ratio of 3 The primary particle between -15; Take by weighing this primary particle of 100 parts of quality, the asphalt of 30 parts of quality, the ferric oxide of 10 parts of quality, the carbon tetrachloride of 30 parts of quality, be placed in high-temperature reactor, inert Under the protection of the atmosphere, heat and stir, among which 300 ° C for 6 hours, 800 ° C for 6 hours, then cool and discharge; the material after granulation is graphitized at 3000 ° C for 24 hours, and the final product is obtained after classification or sieving.

[0043] Its charge and discharge capacity is 361.0mAh / g, the initial efficiency is 96.2%, and the 100-cycle cycle capacity retention rate is 99.17...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size distribution | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com