Long-service-life and high-heat-radiation-performance set-top-box

A high heat dissipation, set-top box technology, applied in the direction of modification, cooling/ventilation/heating transformation, electrical components, etc. through conduction and heat transfer, it can solve the problems of increased surface stress, bulging, and shedding of the coating, and reduce the interface thermal resistance. , The effect of high heat dissipation efficiency and not easy to accumulate dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

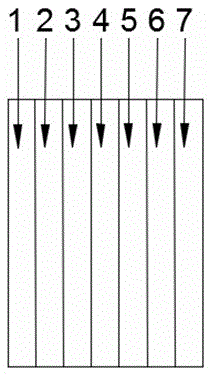

[0021] see figure 1 , in an embodiment of the present invention, a high-life and high-heat-dissipation set-top box is provided with a titanium-silver white finish coating 1, a heat-dissipating connection layer 2, a pre-coating layer 3, a first protective layer 4, and a galvanized sheet 5 in order from top to bottom. , second protective layer 6 and titanium silver white back coating 7;

[0022] The raw materials of the titanium-silver white finish coating 1 according to parts by weight include: 100-120 parts of silicone resin, 10-20 parts of glass fiber powder, 20-30 parts of silver powder, 10-18 parts of zirconium carbide, 2-8 parts of titanium dioxide, 1-3 parts of surfactant;

[0023] The raw materials of the precoat 3 include 30-45 parts by weight of fluorocarbon resin, 10-20 parts of zinc powder, 3-4 parts of silicon carbide, 3-4 parts of boron oxide, and 1-3 parts of surfactant;

[0024] The heat dissipation connection layer 2 includes raw materials in parts by weight: ...

Embodiment 2

[0029] see figure 1 , in an embodiment of the present invention, a high-life and high-heat-dissipation set-top box is provided with a titanium-silver white finish coating 1, a heat-dissipating connection layer 2, a pre-coating layer 3, a first protective layer 4, and a galvanized sheet 5 in order from top to bottom. , second protective layer 6 and titanium silver white back coating 7;

[0030] The raw materials of the titanium-silver white finish coating include by weight: 110 parts of silicone resin, 15 parts of glass fiber powder, 25 parts of silver powder, 14 parts of zirconium carbide, 5 parts of titanium dioxide, and 2 parts of surfactant;

[0031] The raw materials of the pre-coating layer in parts by weight include: 37.5 parts of fluorocarbon resin, 15 parts of zinc powder, 3.5 parts of silicon carbide, 3.5 parts of boron oxide, and 2 parts of surfactant;

[0032] The raw materials of the heat-dissipating connection layer include: 80 parts of propylene-octyl acrylate c...

Embodiment 3

[0037] see figure 1 , in an embodiment of the present invention, a high-life and high-heat-dissipation set-top box is provided with a titanium-silver white finish coating 1, a heat-dissipating connection layer 2, a pre-coating layer 3, a first protective layer 4, and a galvanized sheet 5 in order from top to bottom. , second protective layer 6 and titanium silver white back coating 7;

[0038] The raw material of described titanium-silver white fine coating 1 comprises according to weight: 120 parts of silicone resin, 20 parts of glass fiber powder, 30 parts of silver powder, 18 parts of zirconium carbide, 8 parts of titanium dioxide, 3 parts of surfactant;

[0039] The raw materials of the pre-coat 3 in parts by weight include: 45 parts of fluorocarbon resin, 20 parts of zinc powder, 4 parts of silicon carbide, 4 parts of boron oxide, and 3 parts of surfactant;

[0040] The heat dissipation connecting layer 2 includes raw materials in parts by weight: 90 parts of propylene-o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com