Preparation method of crystal porous composite titanium dioxide for purifying air

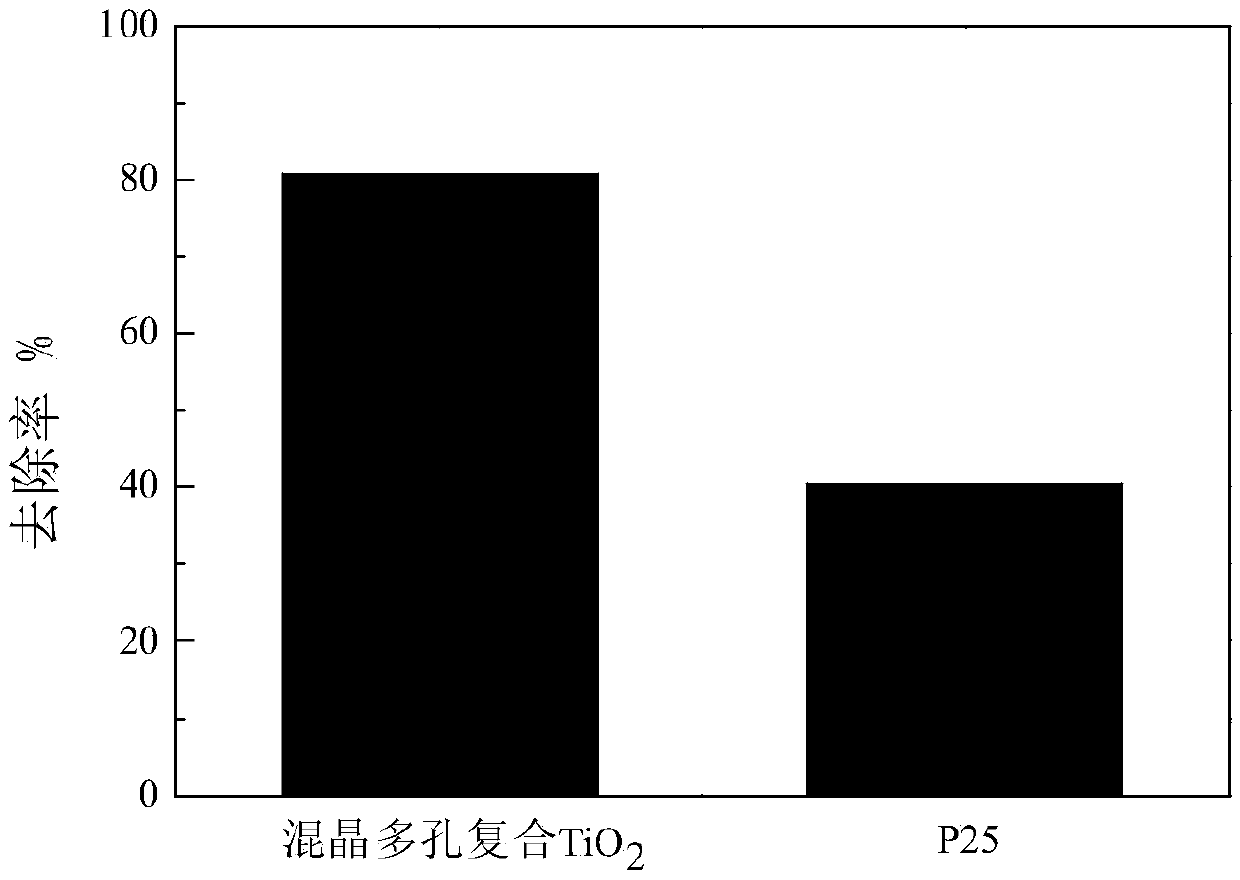

A titanium dioxide and crystal technology, applied in the field of crystal porous composite titanium dioxide and its preparation, can solve the problems of limiting material purification efficiency, amorphous structure, poor optical activity, etc., and achieve adsorption and photocatalytic degradation performance improvement, high crystallinity, and good crystallization degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

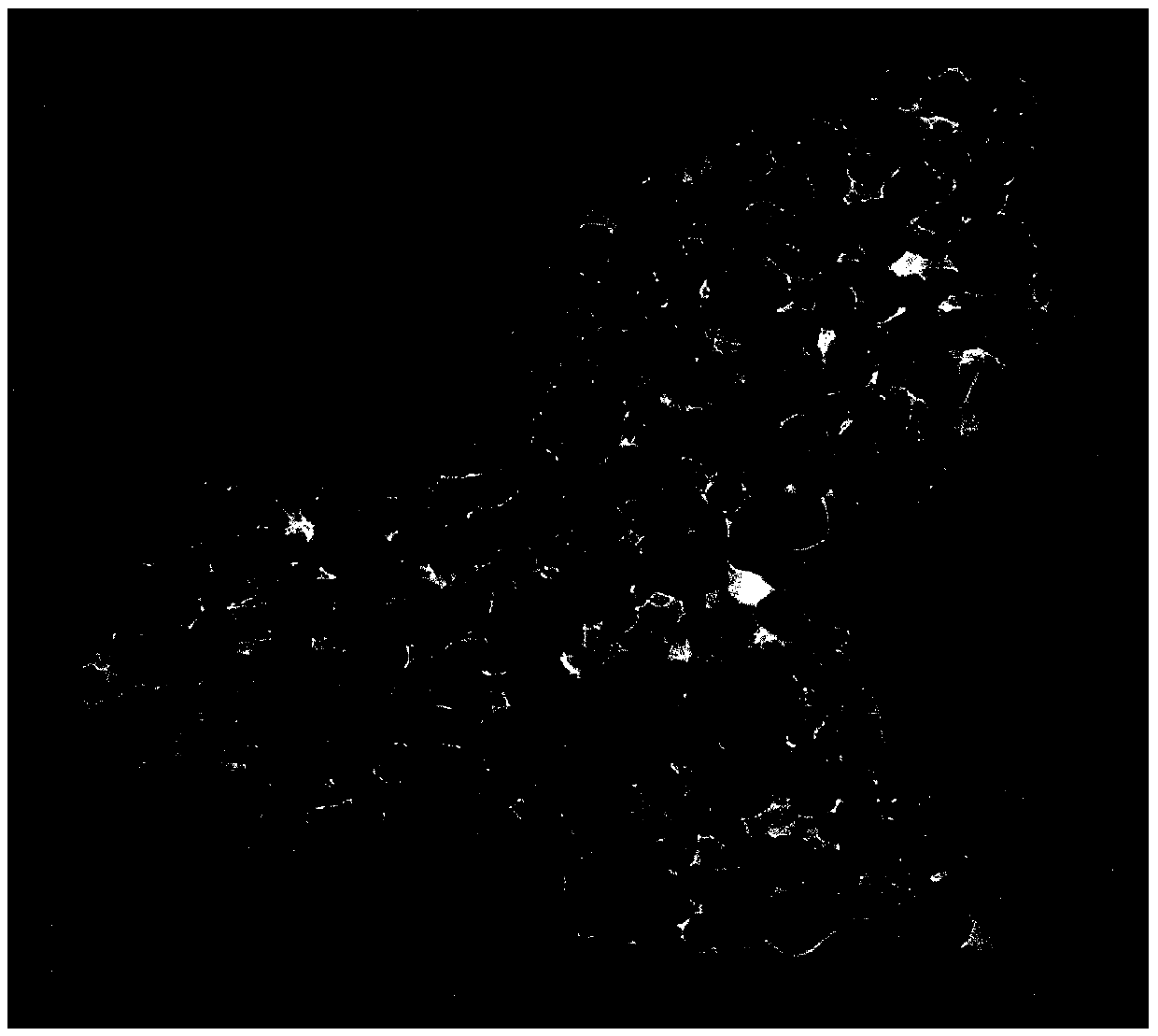

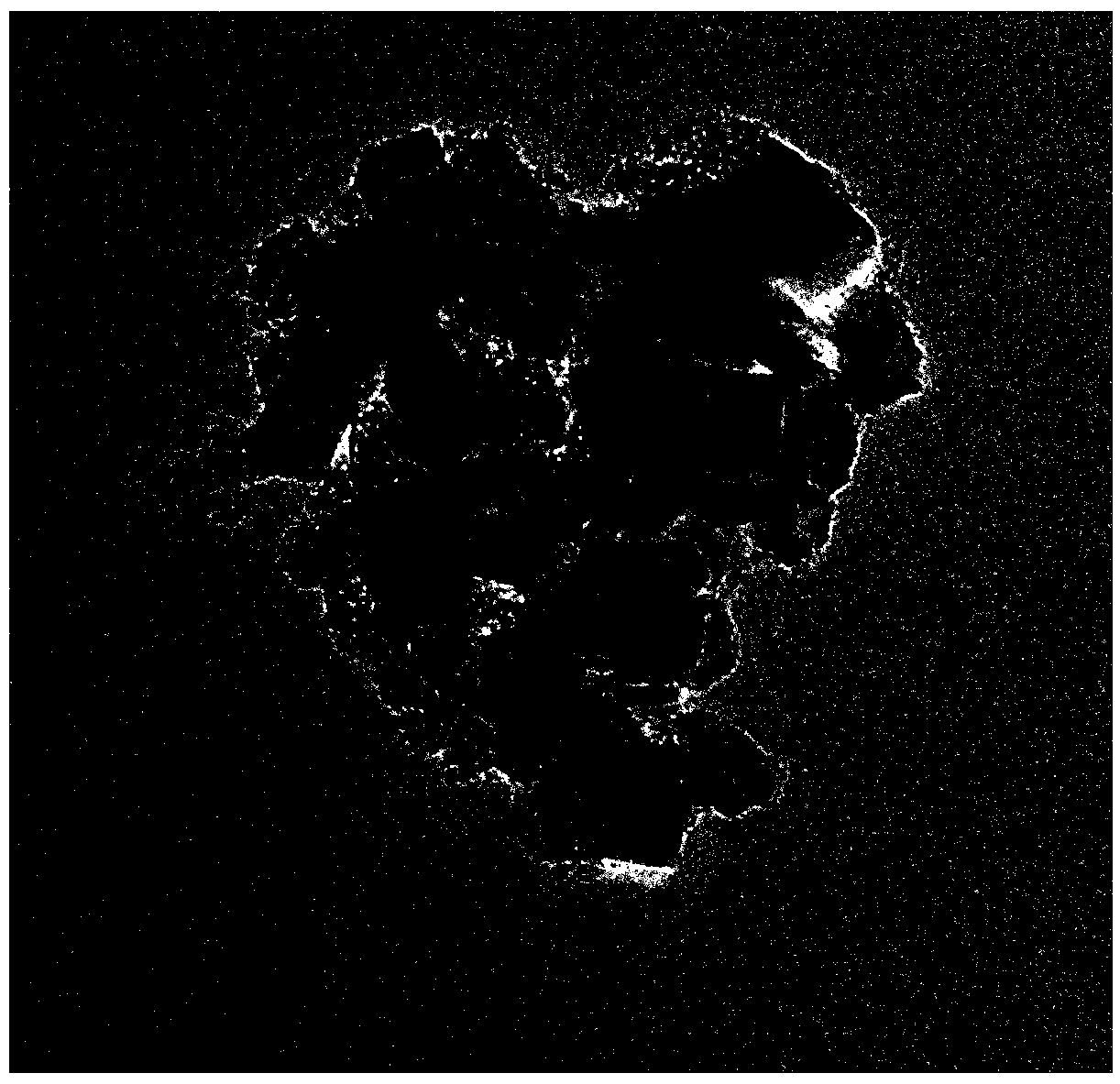

Embodiment 1

[0036] Mix hydrochloric acid and titanium tetrachloride, wherein the molar ratio of hydrogen chloride to titanium tetrachloride is 1:28. Anatase and rutile mixed crystal titanium dioxide (P25, 80% anatase and 20% rutile) were added to the obtained solution to form a suspension with a mass ratio of 1:15, and stirred in a water bath at 70°C for 1 h. The obtained suspension is centrifuged and washed 5 times with water until the pH value is 6, the obtained suspension is centrifuged or filtered, and the obtained solid is naturally air-dried or oven-dried. The obtained solid powder was heated at 500° C. for 30 min to obtain the seed crystal P25 solid. Under vigorous stirring conditions, the prepared seed crystal P25 solid powder was added to absolute ethanol to form a suspension with a concentration of 8 g / L, and the suspension was stirred for 0.5 h. Dodecylamine was added to the above suspension to form a suspension with a concentration of dodecylamine of 2 mmol / L. Add butyl tita...

Embodiment 2

[0041]Mix hydrochloric acid and titanium tetrachloride, wherein the molar ratio of hydrogen chloride to titanium tetrachloride is 1:28. Anatase titanium dioxide was added to the obtained solution to form a suspension with a mass ratio of 1:10, and stirred in a water bath at 70°C for 1 hour. The obtained suspension was centrifuged and washed 7 times with water until the pH value was 7, the obtained suspension was centrifuged or filtered, and the obtained solid was naturally air-dried or oven-dried. The obtained solid powder was heated at 600° C. for 60 min to obtain a seed crystal anatase titanium dioxide solid. Under vigorous stirring conditions, the obtained anatase-type titanium dioxide solid powder with seed crystals was added into absolute ethanol to form a suspension with a concentration of 10 g / L, and the suspension was stirred for 1 h. Dodecylamine was added to the above suspension to form a suspension with a concentration of dodecylamine of 6 mmol / L. Add butyl titana...

Embodiment 3

[0047] Mix hydrochloric acid and titanium tetrachloride, wherein the molar ratio of hydrogen chloride to titanium tetrachloride is 1:30. Crystalline titanium dioxide was added to the obtained solution to form a suspension with a mass ratio of 1:5, and stirred in a water bath at 50°C for 5 hours. The obtained suspension was centrifuged and washed 7 times with water until the pH value was 7, the obtained suspension was centrifuged or filtered, and the obtained solid was naturally air-dried or oven-dried. The obtained solid powder was heated at 350° C. for 100 min to obtain a seed crystal titanium dioxide solid. Under vigorous stirring conditions, the prepared seed crystal titanium dioxide solid powder was added into absolute ethanol to form a suspension with a concentration of 20 g / L, and the suspension was stirred for 1 h. Dodecylamine was added to the above suspension to form a suspension with a concentration of dodecylamine of 0.1 mmol / L. Butyl titanate was added to the abs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com