Heterogeneous catalyst for catalyzing asymmetric Aldol reaction and preparation method thereof

A heterogeneous catalyst and asymmetric technology, which is applied in catalytic reactions, preparation of organic compounds, physical/chemical process catalysts, etc., can solve problems such as complex operation, difficult mass transfer of multiphase reactions, and harsh experimental conditions. The effect of mild reaction conditions, simple preparation process and controllable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

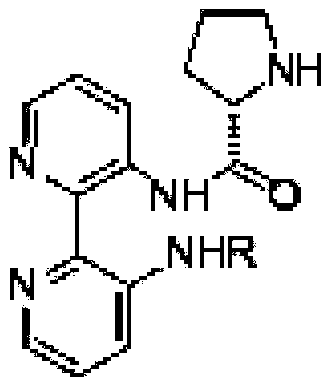

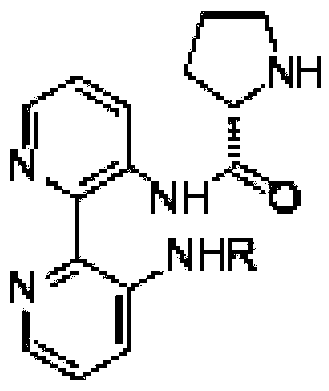

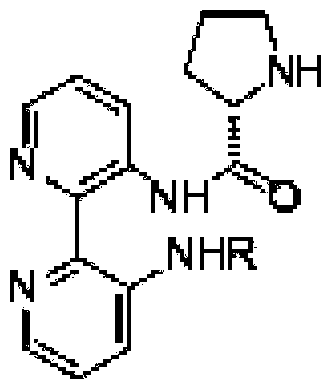

[0030] The heterogeneous catalyst in the present invention is that the bipyridyl proline derivative is immobilized on the metal-modified dual-model mesoporous silica nanometer material carrier. The metal-modified dual-model mesoporous silicon oxide nanomaterial carrier has mesopores with a diameter of 2-4nm and spherical particle stacking pores with a diameter of 10-30nm. The silicon oxide nanomaterial itself is a spherical particle of 40-100nm, and the spherical particle has mesopores of 2-4nm. When a large number of silicon oxide nanomaterials accumulate with each other, a stacking hole will appear, and the diameter of the stacking hole is 10-30nm. Wherein, the molecular structural formula of bipyridyl proline derivative is

[0031]

[0032] Where R stands for H, L-proline, N-Cbz-prolinamide, 3-CH 3 C 6 h 4 CO,(CH 3 ) 3 CO,CH 3 One of a kind in CO.

Embodiment 2

[0034] This embodiment provides a method for preparing a heterogeneous catalyst for catalytic asymmetric Aldol reaction in Example 1, comprising the following steps:

[0035] Step 1. Prepare dual-model mesoporous silicon oxide nanomaterials.

[0036] Step 2, preparing a metal-modified dual-model mesoporous silica nanomaterial carrier, including the following sub-steps:

[0037] Step 21, drying the dual-model mesoporous silica nanomaterial;

[0038] Step 22, mixing the dried mesoporous silica nanomaterial with a methanol solution of metal acetate and stirring to react, so that metal elements are immobilized on the mesoporous silica nanomaterial;

[0039] Step 23, evaporating the solvent, and vacuum drying;

[0040] Step 24, washing with water and methanol for several times, and drying to obtain the metal-modified dual-model mesoporous silica nanomaterial carrier, the metal is bonded to the silicon hydroxyl group on the surface of the silica nanomaterial, and is uniformly dist...

Embodiment 3

[0062] Step 1: Preparation of dual-model mesoporous silica nanomaterials

[0063] Dissolve 2.81g of octadecyltrimethylammonium bromide in 104g of distilled water, stir until dissolved, pipette 8mL of ethyl orthosilicate into the solution, add 2.6ml of ammonia water with a mass fraction of 25%, stir until white lumps are produced shaped gel, filtered, washed, dried, and the obtained white powder was heated to 550° C. for 5 hours and calcined to obtain a dual-model mesoporous silica nanomaterial with a diameter of 4 nm in the primary channel and a diameter of 30 nm in the secondary channel structure.

[0064] Here, the primary pores refer to the mesoporous pores on the spherical particles of the silicon oxide nanomaterials, and the secondary pores refer to the spherical particle accumulation pores generated by the particles of the silicon oxide nanomaterials stacked on each other.

[0065] Step 2: Preparation of metallic nickel-modified dual-model mesoporous silica nanomaterial ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com