Soluble graphene nanoribbon as well as synthetic method and application thereof

A graphene nanobelt and a synthesis method technology are applied in graphene nanobelt, nanotechnology, nanotechnology and other directions, can solve the problems of low yield, high cost, complicated route and the like, and achieve high mobility, reliable process, The effect of a wide range of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of soluble graphene nanoribbon, its synthetic method comprises the steps:

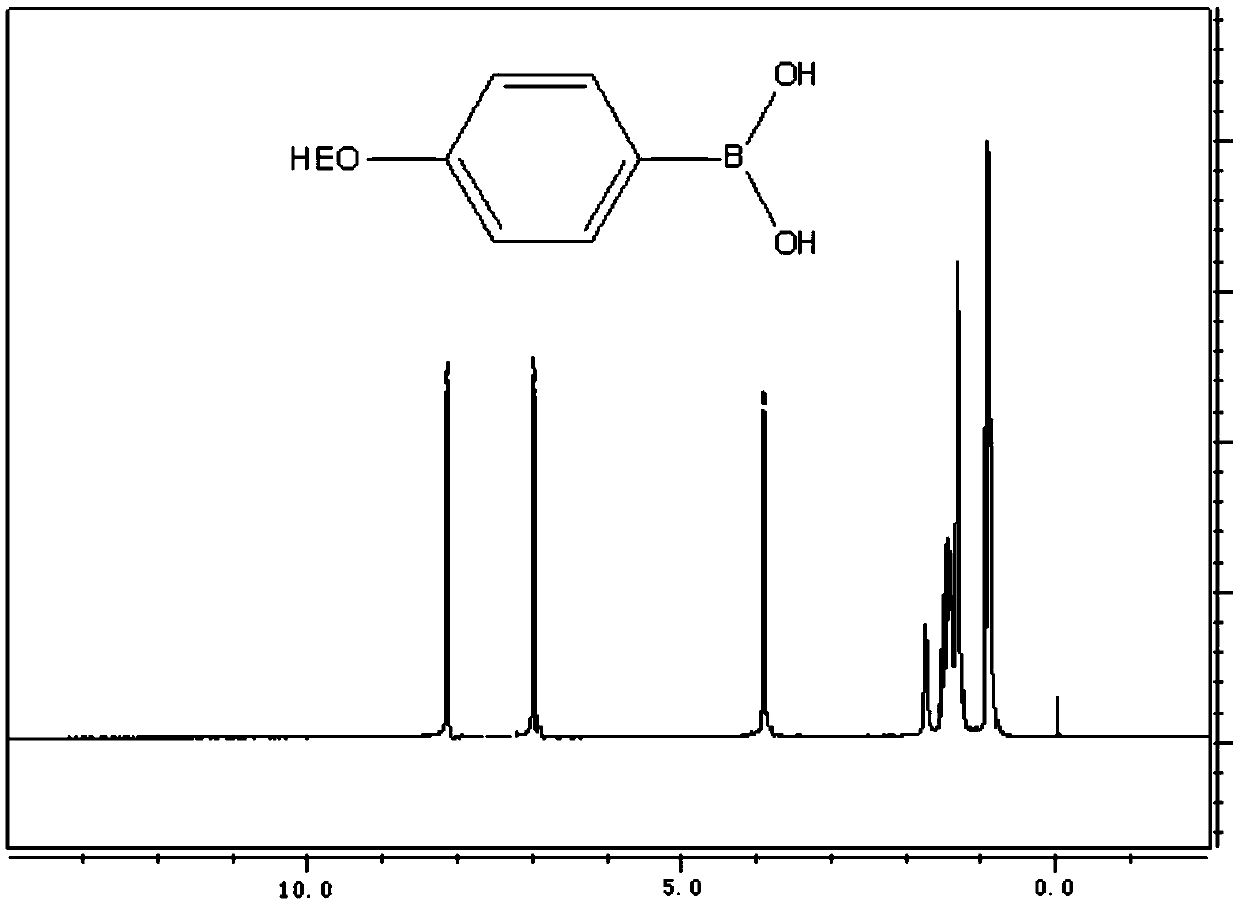

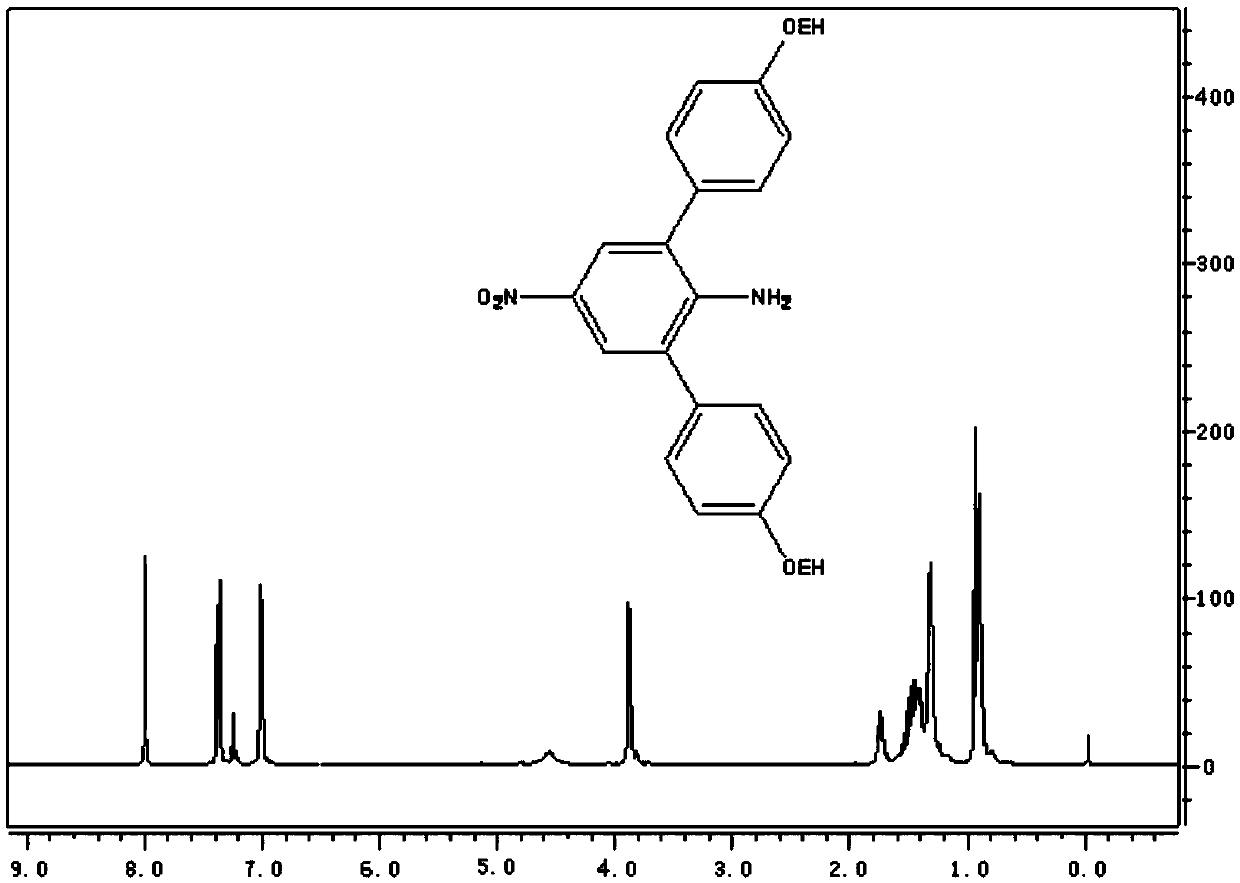

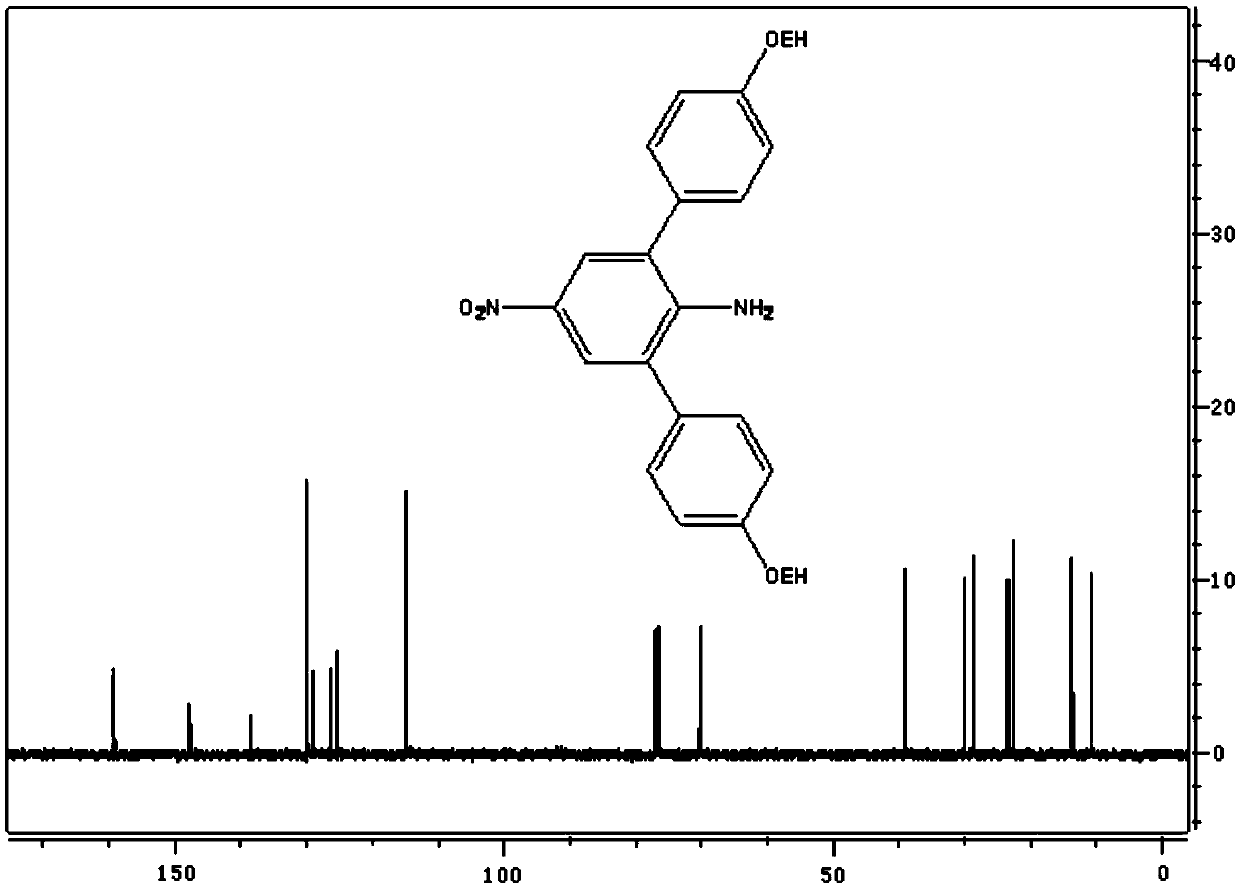

[0038] (1) Synthesis of 4-(2-ethylhexyloxy)phenylboronic acid:

[0039] The synthetic route is shown in the following formula:

[0040]

[0041] The specific operation is:

[0042] Take activated magnesium powder (100mmol, 2.4g), 4-(2-ethylhexyloxy) bromobenzene (100mmol, 28.5g) in a 500mL three-necked bottle, change argon three times, inject tetrahydrofuran (THF) 100mL, heat Reflux for 3 hours (until the magnesium powder disappears completely), cool to room temperature, add THF150mL, cool down to -80°C, add 24mL trimethyl borate at one time, react at -65°C for 3 hours, and react overnight without removing the thermos; the next day Add 20 mL of concentrated sulfuric acid and 100 mL of water dropwise into ice, stir for half an hour, separate layers, add water, extract with ethyl acetate, wash with saturated brine, and dry over magnesium sulfate; A 25 cm column was filled with silica ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com