High nutrition pure solid saccharum officinarum juice and preparation method thereof

A pure solid, high-nutrition technology, applied in the fields of food science, food preservation, application, etc., can solve the problems of loss of nutrient functional substances, discoloration, change of the aroma and flavor of the original sugarcane juice, etc., to achieve convenient carrying and transportation, golden color, Long shelf life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: powder

[0040] 1) Squeeze fresh sugar cane, and take the first initial pressing juice;

[0041] 2) After the first initial press juice is filtered through a 40-mesh sieve, the enzyme is instantaneously inactivated by high temperature at a temperature of 140°C for 5 seconds;

[0042] 3) the sugarcane juice after deenzyme is centrifuged with a centrifuge at 21000 rpm to get the clarified liquid;

[0043] 4) The clarified liquid is filtered through an ultrafiltration membrane with a pore size of 0.05 μm;

[0044] 5) The filtrate is spray-dried, the air inlet gas is air, the inlet air temperature is 130°C, the outlet air temperature is 60°C, and the wind speed is 0.5m 3 / min, the feed flow rate is 3000mL / h, the feed concentration is 7%, the pressure is -200pa, the drying time is 10s, and the product is collected to get final product.

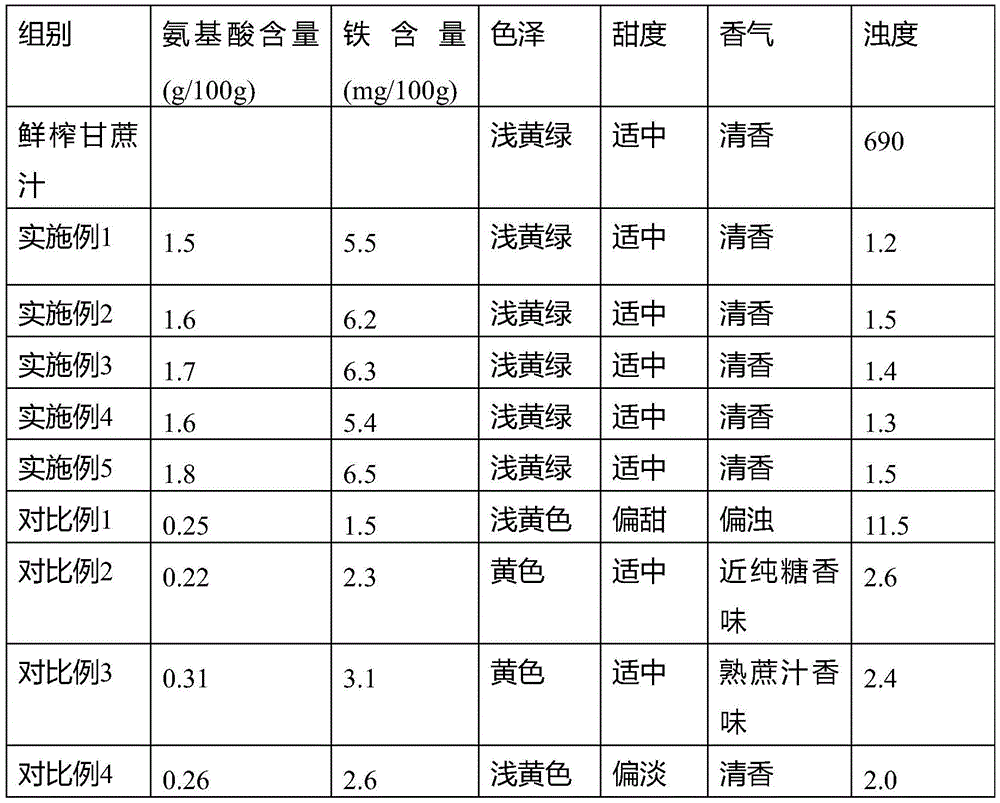

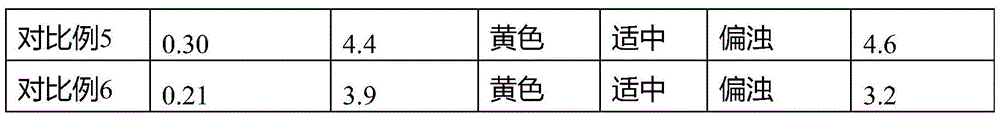

[0045] The sensory indexes are compared with fresh sugarcane juice after being dissolved in water with a weight ratio of 5 ...

Embodiment 2

[0046] Embodiment 2: Granules

[0047] 1) Squeeze fresh fruit cane, and take the first initial pressing juice;

[0048] 2) After the first initial press juice is filtered through a 60-mesh sieve, the enzyme is instantaneously inactivated by high temperature at a temperature of 180°C for 3 seconds;

[0049] 3) the sugarcane juice after deenzyme is centrifuged with a centrifuge at 11000 rpm to get the clarified liquid;

[0050] 4) The clarified liquid is filtered through an ultrafiltration membrane with a pore size of 0.1 μm;

[0051] 5) The filtrate is spray-dried, the air inlet gas is nitrogen, the air inlet temperature is 150°C, the outlet air temperature is 70°C, and the wind speed is 1.0m 3 / min, the feed flow rate is 5000mL / h, the feed concentration is 15%, the pressure is -300pa, and the drying time is 5s. Collect the product and make it into granules.

[0052] Add water with a weight ratio of 25 times to dissolve and compare various sensory indicators with fresh sugar...

Embodiment 3

[0053] Embodiment 3: tablet

[0054] 1) Fresh sugar cane and fruit cane are mixed and squeezed to obtain the squeezed juice;

[0055] 2) After the sugarcane juice is filtered through a 50-mesh sieve, the enzyme is instantaneously inactivated by high temperature at a temperature of 160°C for 4s;

[0056] 3) the sugarcane juice after deenzyme is centrifuged with a centrifuge at 16000 rpm to get the clarified liquid;

[0057] 4) The clarified liquid is filtered through an ultrafiltration membrane with a pore size of 0.075 μm;

[0058] 5) The filtrate is spray-dried, the operating parameters are helium as the air inlet gas, the inlet air temperature is 120°C, the outlet air temperature is 55°C, and the wind speed is 0.75m 3 / min, the feed flow rate is 4000mL / h, the feed concentration is 20%, the pressure is -250pa, and the drying time is 7s; collect the products and make them into flakes.

[0059] After adding water with a weight ratio of 15 times and dissolving it, the sensory...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com