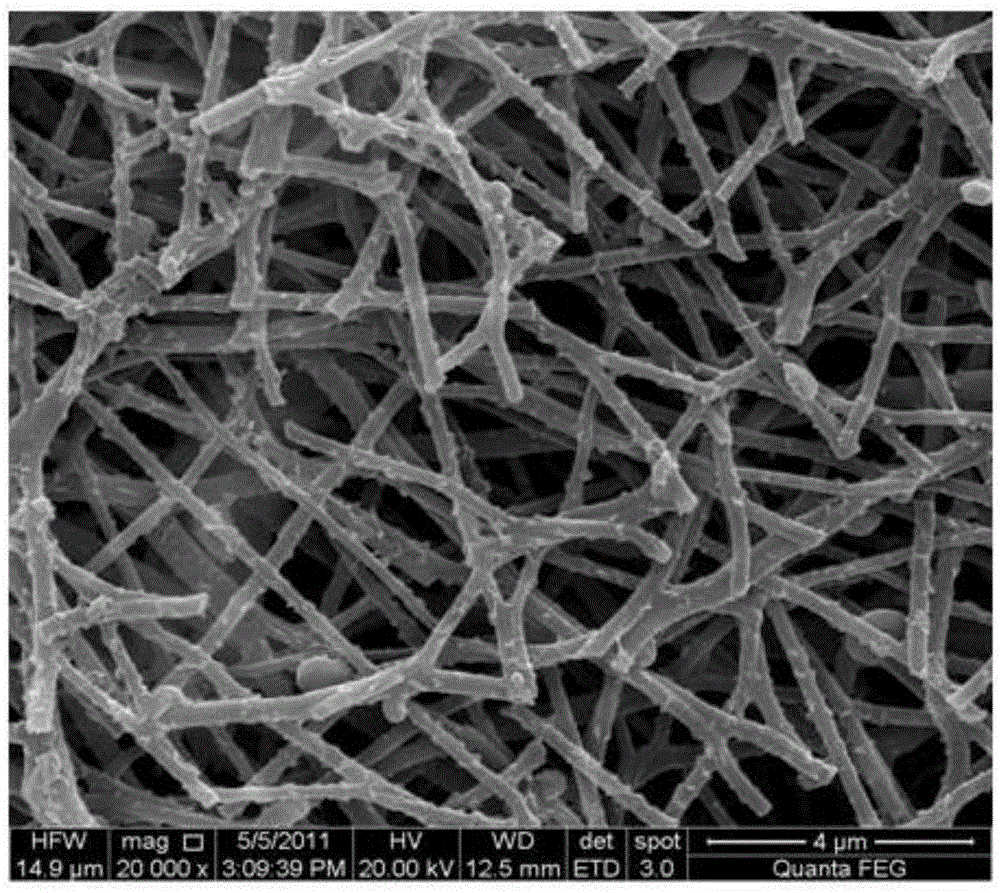

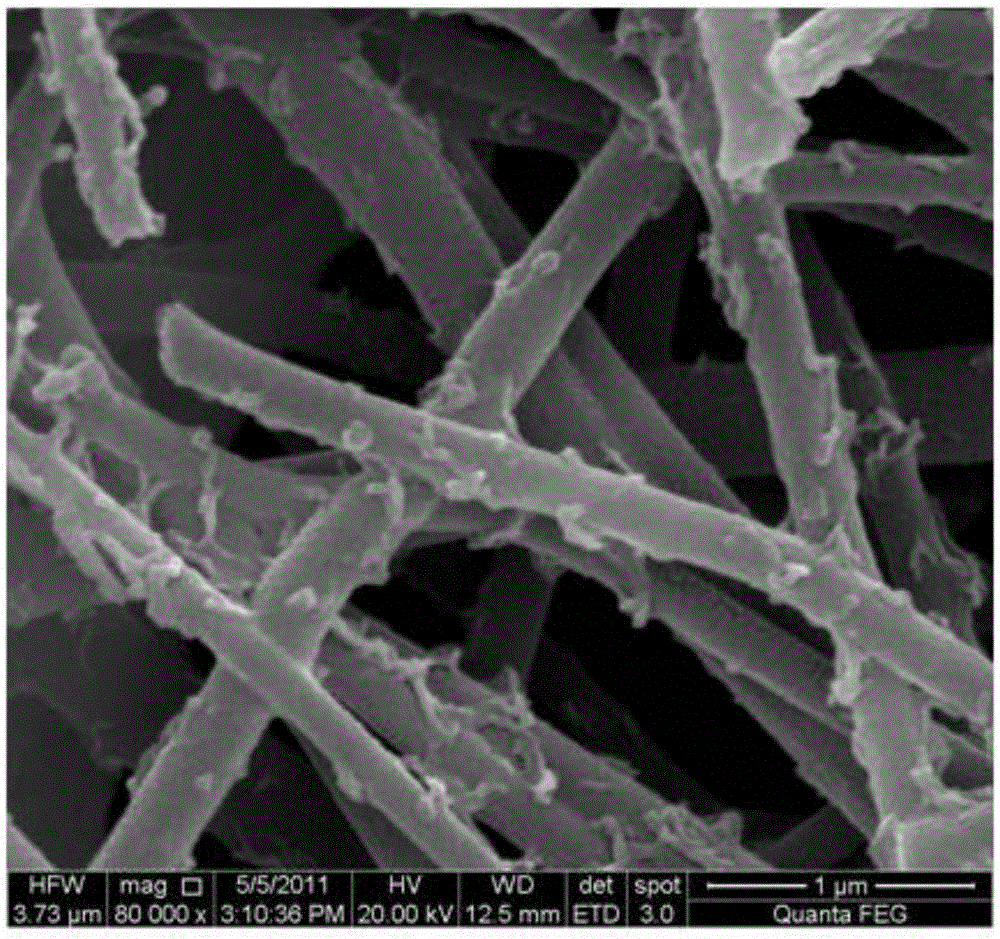

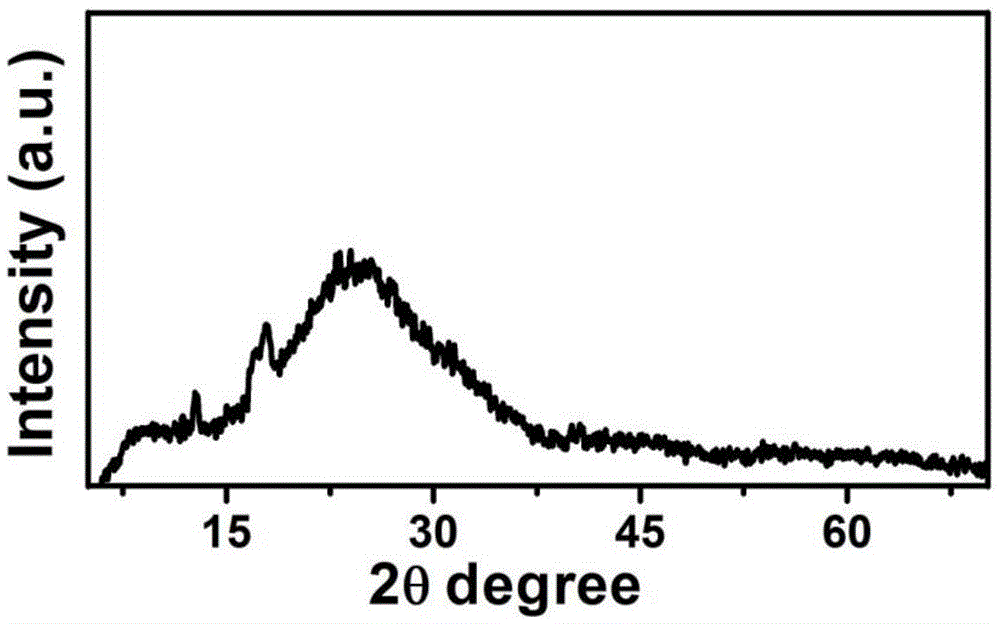

Preparing method for nanowire iron phthalocyanine/carbon nanofiber heterojunction composite material

A technology of carbon nanofibers and composite materials, applied in the field of composite materials, can solve problems such as low product yield, difficulty in forming heterojunctions, complexity, etc., and achieve the effect of achieving a firm combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Preparation of iron-containing carbon nanofibers

[0027] 1.5g polyacrylonitrile (PAN) and 0.032g FeCl 2 4H 2 O was dissolved in 12mL N,N-dimethylformamide (DMF), stirred magnetically for 24 hours, stirred until uniform, transparent and viscous, then transferred to a 10ml syringe, and connected to a metal joint through a catheter, using flow The controller controls the mixed solution to keep the flow rate at 0.1-10 sccm; use a flat electrode, a parallel metal plate electrode or a rotatable roller electrode as the receiving electrode, connect the two poles of the high-voltage electrostatic device to the metal joint and the receiving electrode respectively, and pass through the high-voltage electrostatic device Provide a high voltage of 10kV to start spinning to obtain organic nanofibers containing iron salts;

[0028] Put the organic nanofibers containing iron salts in a tubular reactor for oxidation and carbonization: adjust the temperature of the tubular reactor,...

Embodiment 2

[0032] (1) Preparation of iron-containing carbon nanofibers

[0033] 1.5g polyacrylonitrile (PAN) and 0.015gFeCl 2 4H 2 O was dissolved in N,N-dimethylformamide (DMF), and the mass percentage of polyacrylonitrile in DMF was controlled to be 11.7%, magnetically stirred for 21 hours, and then transferred to a 10ml syringe after stirring until uniform, transparent and viscous. Connect it to a metal joint through a conduit, use a flow controller to control the mixed solution to maintain the flow rate at 5 sccm; use a flat electrode, a parallel metal plate electrode or a rotatable roller electrode as the receiving electrode, and connect the two poles of the high voltage electrostatic device respectively On the metal joint and the receiving electrode, a high voltage of 10kV is provided through a high-voltage electrostatic device to start spinning to obtain organic nanofibers containing iron salts;

[0034] Put the organic nanofibers containing iron salts in a tubular reactor for o...

Embodiment 3

[0038] (1) Preparation of iron-containing carbon nanofibers

[0039] 1.5g polyacrylonitrile (PAN) and 0.045gFeCl 2 4H 2 O was dissolved in N,N-dimethylformamide (DMF), and the mass percentage of polyacrylonitrile in DMF was controlled to be 11.5%, magnetically stirred for 23 hours, stirred until uniform, transparent and viscous, and then transferred to a 10ml syringe. Connect it to a metal joint through a conduit, use a flow controller to control the mixed solution to maintain the flow rate at 6 sccm; use a flat electrode, a parallel metal plate electrode or a rotatable roller electrode as a receiving electrode, and connect the two poles of the high voltage electrostatic device respectively On the metal joint and the receiving electrode, a high voltage of 10kV is provided through a high-voltage electrostatic device to start spinning to obtain organic nanofibers containing iron salts;

[0040] Put the organic nanofibers containing iron salts in a tubular reactor for oxidation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com