Nano titanium dioxide/graphene composite material and preparation method thereof

A nano-titanium dioxide and composite material technology is applied in the field of nano-titanium dioxide/graphene composite materials and their preparation, which can solve the problems of no chemical bonding, incomplete bonding, and inability to composite, so as to suppress accumulation and agglomeration, be difficult to decay, and improve electrical conductivity. poor sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

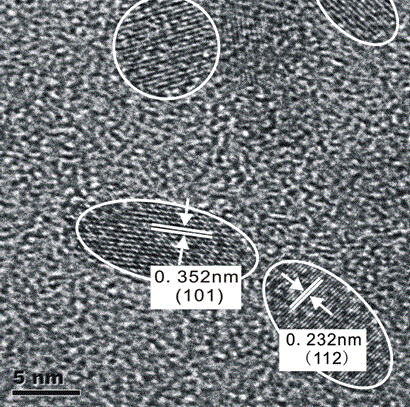

[0036] A preparation method of nano-titanium dioxide / graphene composite material, comprising the following steps:

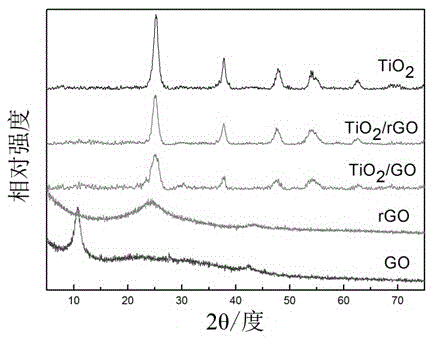

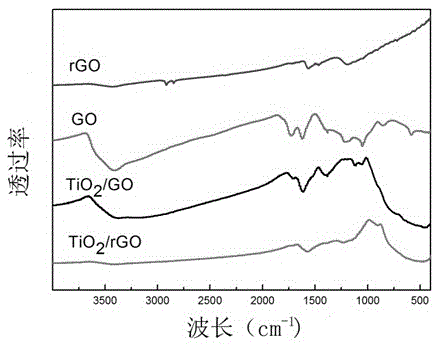

[0037] (1) Preparation of graphene oxide colloid: use the improved hummer method to prepare graphite oxide, add flake graphite (2g) into ice-bathed concentrated sulfuric acid (98wt%, 69ml), stir for 30min, add potassium permanganate (8g) The above solution was stirred for 2h. Moved to 35 ℃ water bath and stirred for 12h. Add 276ml deionized water three times, after adding, add H 2 o 2 (30%, 25ml) centrifuge, wash, dry and grind to get graphite oxide. 0.2 g of graphite oxide powder was ultrasonically dispersed in 400 ml of deionized water to obtain graphene oxide colloid with a concentration of 0.5 mg / ml.

[0038](2) Preparation of titanium dioxide colloid: Mix glacial acetic acid (20.00ml) and tetrabutyl titanate (20.00ml) and stir for 30 minutes to obtain solution A, mix glacial acetic acid (5.00ml) and deionized water (95ml) to obtain solution B, put Drop ...

Embodiment 2

[0045] A preparation method of nano-titanium dioxide / graphene composite material, comprising the following steps:

[0046] Graphene oxide colloid and titanium dioxide colloid were prepared according to the same method as in Example 1. Measure 6.2ml of titanium dioxide colloid and drop it into the graphene oxide colloid (400ml, 0.5mg / ml) in a stirring state. Pour off the supernatant, transfer the turbid floc liquid to a high-temperature reaction kettle, add 0.5g sodium borohydride, and react at 140°C for 14 hours. After the reaction is complete, cool, centrifuge, dry, and grind to obtain the mass ratio of titanium dioxide to graphene It is a 5:5 titanium dioxide / graphene composite material.

[0047] Mix the titanium dioxide / graphene composite, acetylene black, and PTFE at a mass ratio of 80:10:10, add an appropriate amount of ethanol, disperse ultrasonically, coat the nickel foam, dry, press into tablets, and make a cyclic voltammetry curve measurement (see Figure 4 ), the c...

Embodiment 3

[0049] A preparation method of nano-titanium dioxide / graphene composite material, comprising the following steps:

[0050] Graphene oxide colloid and titanium dioxide colloid were prepared according to the method of Example 1. Measure 2.6ml of titanium dioxide colloid and drop it into graphene oxide colloid (400ml, 0.5mg / ml) under stirring state. Remove the supernatant, transfer the turbid floc liquid to a high-temperature reaction kettle, add 0.5g sodium borohydride, and react at 140°C for 14 hours. After the reaction is complete, cool, centrifuge, dry, and grind to obtain a mass ratio of titanium dioxide to graphene A titanium dioxide / graphene composite material with a mass ratio of 3:7. Mix titanium dioxide / graphene composite, acetylene black, and PVDF at a mass ratio of 80:10:10, add a certain amount of NMF (1-methylpyrrolidone), grind it into a slurry, coat it on copper foil, and bake dry, cut into pieces, assembled into a button battery, and measured on a charge-dischar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com