Preparation method for stannous sulfide nanosheet and photoelectric detector prepared based on stannous sulfide nanosheet

A technology of stannous sulfide and nanosheets, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of lack of stannous sulfide nanosheets, complicated preparation process, and high risk of operation , to achieve the effects that are conducive to popularization and application, good photoelectric response, and high operational safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

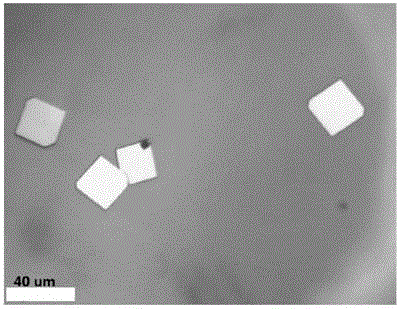

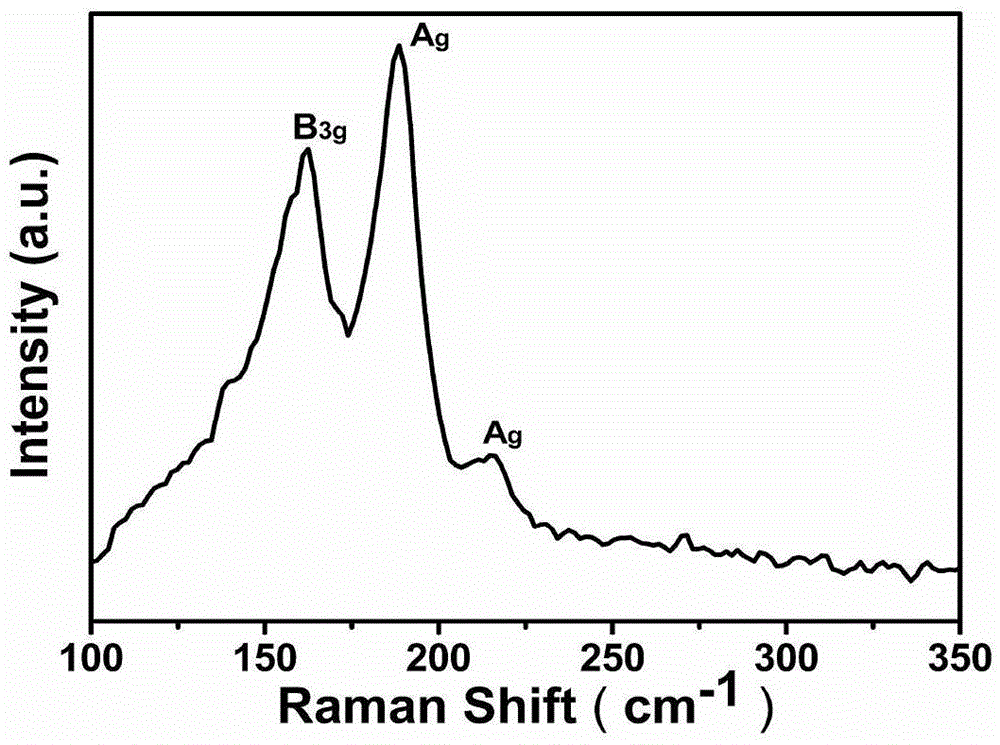

[0025] Embodiment 1: a kind of preparation method of stannous sulfide nanosheet, specifically comprises the following steps:

[0026] Step 1: First put the SiO 2 / Si substrate in H 2 SO 4 :H 2 o 2 Soak in the mixed solution prepared at a ratio of 3:1 for 1 hour, and then ultrasonically clean it with deionized water, acetone, alcohol, and deionized water once to obtain a clean SiO2 / Si substrate. Then place 0.02g of stannous sulfide powder in a clean quartz boat, place the cleaned SiO2 / Si substrate horizontally directly above the quartz boat; place the quartz boat in the middle of the quartz tube heating zone, and seal the quartz tube;

[0027] Step 2: Pass inert gas argon or nitrogen into the quartz tube as a protective gas, the gas flow rate is 300 sccm, and continue to ventilate for 20 minutes to completely discharge the air in the quartz tube;

[0028] Step 3: Heating the quartz tube: heat up the quartz tube, and during the heating process, when the temperature rises to...

Embodiment 2

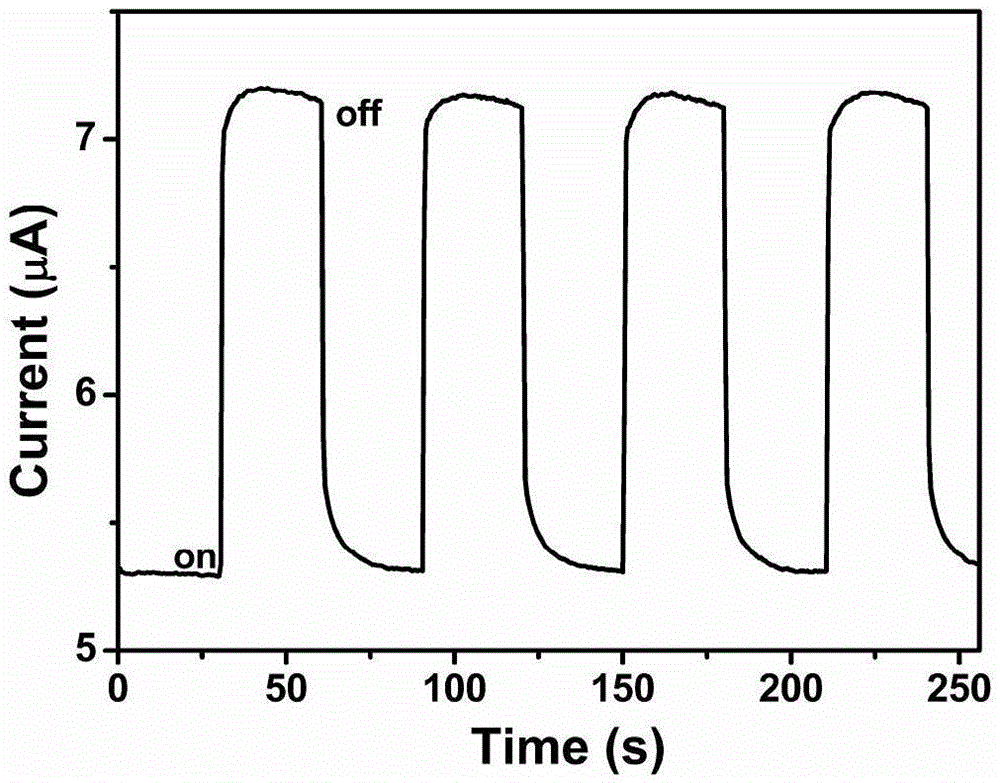

[0033] Embodiment 2: A photoelectric device prepared by stannous sulfide nanosheets, the stannous sulfide nanosheets prepared in Example 1 are made into photoelectric devices by means of photolithography and other technical means, and the optoelectronic devices are tested by CHI660D electrochemical workstation. The photoresponse of infrared light, the infrared light (638nm) response curve of the optoelectronic device that makes in the present embodiment sees image 3 , the results show that the device has very good photodetection performance.

Embodiment 3

[0034] Embodiment 3: a kind of preparation method of stannous sulfide nanosheet, described preparation method comprises the steps:

[0035] Step 1, put stannous sulfide powder in a clean quartz boat, clean up SiO 2 The / Si substrate is placed horizontally directly above the quartz boat. Then place the quartz boat in the middle of the heating zone of the quartz tube to seal the quartz tube;

[0036] Step 2. Pass an inert gas into the quartz tube for 10-30 minutes to exhaust the air in the quartz tube;

[0037] Step 3. Heat the quartz tube to 700-750°C; reduce the flow rate of the inert gas during the heating process;

[0038] Step 4. Keep the quartz tube in a high temperature zone with a temperature of 700-720°C for 6-12 minutes, and then let it cool down naturally;

[0039] Step 5. After the quartz tube is naturally cooled to 560-600°C, push the quartz tube out of the tube furnace to cool down quickly;

[0040] Step 6. When the temperature of the quartz tube drops to room ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com