Preparation method and application of iron-sulfur heterogeneous Fenton-like catalyst

A catalyst, Fenton's technology, used in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of heterogeneous Fenton-like catalysts adapting to a narrow pH range and complex preparation processes, and achieves high Treatment effect, simple preparation process, and effect of improving catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

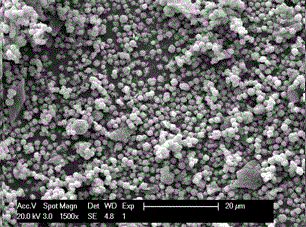

Image

Examples

Embodiment 1

[0039] (1) Dissolve ferrous sulfate heptahydrate in water, stir to dissolve, and make a solution with a concentration of 0.06mol / L; dissolve sodium hydrosulfide and sodium sulfide in water respectively, and make a solution with a concentration of 0.2mol / L Solution, sodium sulfite is made into a solution with a concentration of 0.08mol / L, and the dispersant ammonium citrate is made into a solution with a concentration of 1mol / L for subsequent use.

[0040](2) Add 0.1‰ volume of dispersant to the ferrous solution, and stir evenly on a magnetic stirrer.

[0041] (3) Under magnetic stirring, slowly pour the sodium hydrosulfide and sodium sulfide solutions into the solution prepared in step (2) in sequence, and at the same time add NaOH solution dropwise to adjust the pH of the solution to maintain it at 5.0~5.5, Stir magnetically for 10 min.

[0042] (4) Slowly add sodium sulfite solution to the solution obtained in step (3), add HCl dropwise, maintain the pH at 5.0-5.5, and stir...

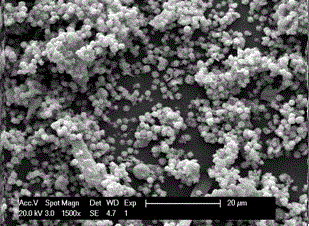

Embodiment 2

[0047] (1) Dissolve ferrous sulfate heptahydrate in water, stir to dissolve, and make a solution with a concentration of 0.1mol / L; dissolve sodium hydrosulfide and sodium sulfide in water respectively, and make a solution with a concentration of 0.3mol / L Solution, sodium sulfite is made into a solution with a concentration of 0.1mol / L, and the dispersant ammonium citrate is made into a solution with a concentration of 1mol / L for subsequent use.

[0048] (2) Add 0.1‰ volume of dispersant to the ferrous solution, and stir evenly on a magnetic stirrer.

[0049] (3) Under magnetic stirring, slowly pour the sodium hydrosulfide and sodium sulfide solutions into the solution prepared in step (2) in sequence, and at the same time add NaOH solution dropwise to adjust the pH of the solution to maintain it at 5.0~5.5, Stir magnetically for 15 min.

[0050] (4) Slowly add sodium sulfite solution to the solution obtained in step (3), add HCl dropwise, maintain the pH at 5.0-5.5, and stir ...

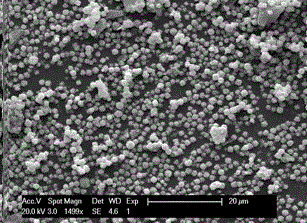

Embodiment 3

[0055] Take 200mL of the effluent from the secondary sedimentation tank of the biological treatment of printing and dyeing wastewater into a 250mL beaker. The COD of the water sample is 128mg / L, and the pH=7.2. 2mM hydrogen peroxide and 0.5mM sodium persulfate were added to the water sample, and 0.5g / L of the heterogeneous Fenton-like activator prepared in Example 1 was added thereto, and the reaction was stirred for 60min. After the reaction, the COD is 45mg / L, which meets the first-class A emission standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com